An anti-rust treatment device for the production of lighting fixtures

A technology for anti-rust treatment and lighting lamps, which is applied in the direction of spraying devices, etc., can solve the problems of uneven plastic powder, poor spray effect on the outer wall of lamps, poor anti-rust effect, etc., achieve uniform distribution, improve the effect of anti-rust treatment, and improve The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

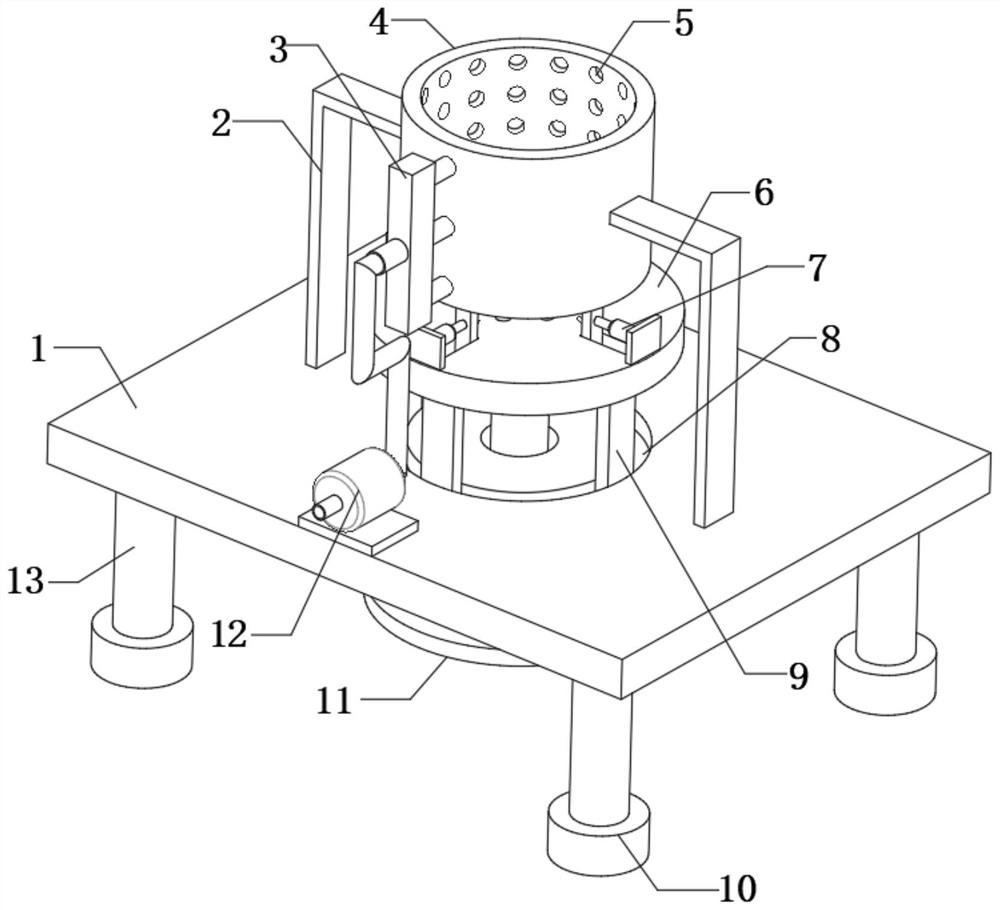

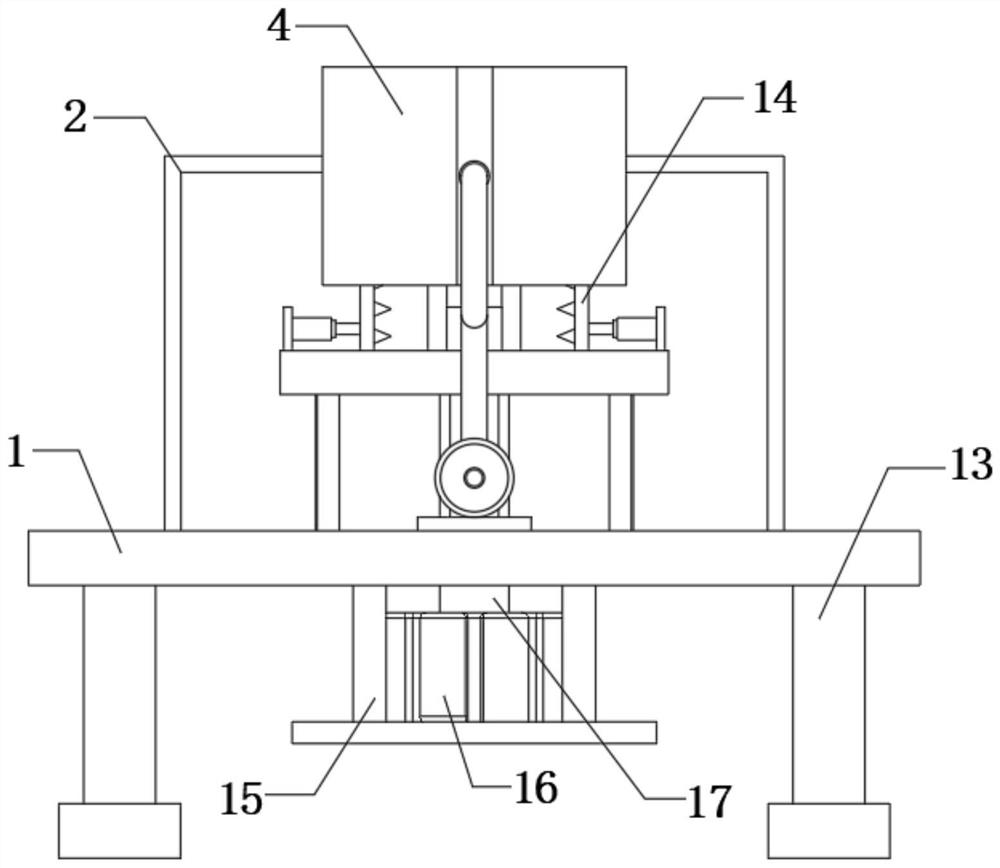

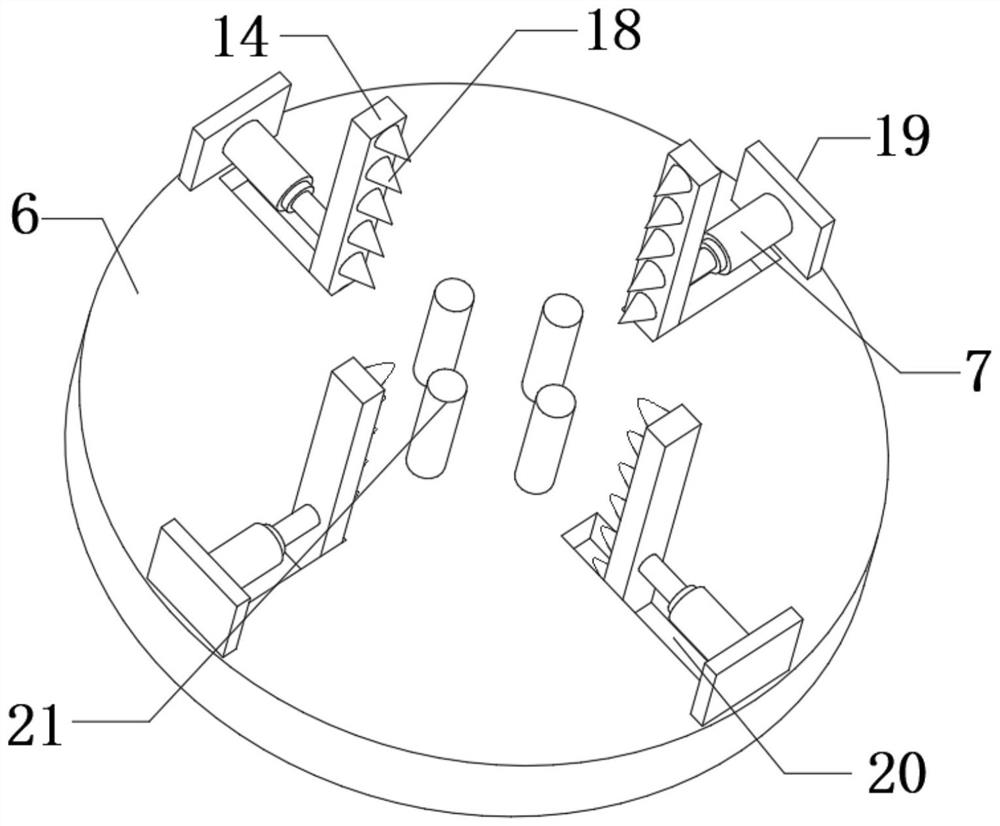

[0028] refer to Figure 1-5 , an antirust treatment device for the production of lighting fixtures, comprising a workbench 1, two fixing frames 2 are fixedly connected to the top outer wall of the workbench 1, and the same spraying tube is fixedly connected to the outer walls of the opposite sides of the two fixing frames 2 4. Spraying holes 5 are opened equidistantly on the inner and outer walls of the spraying cylinder 4, and the top outer wall of the workbench 1 is fixedly connected with a feed pump 12, and the outer wall of the spraying cylinder 4 is equidistantly provided with feeding ends. One end is fixedly connected with the same shunt pipe 3, and the feeding end of the feed pump 12 is connected to the inner wall of the shunt pipe 3 through a pipeline. The inner wall is equidistantly connected with a drain plate 22 by a hinge, and the drain plate 22 is centered on the feeding end of the spraying cylinder 4 to radiate to both ends. A connecting spring 23 is fixedly con...

Embodiment 2

[0037] refer to Figure 1-6, an antirust treatment device for the production of lighting fixtures, comprising a workbench 1, two fixing frames 2 are fixedly connected to the top outer wall of the workbench 1, and the same spraying tube is fixedly connected to the outer walls of the opposite sides of the two fixing frames 2 4. Spraying holes 5 are opened equidistantly on the inner and outer walls of the spraying cylinder 4, and the top outer wall of the workbench 1 is fixedly connected with a feed pump 12, and the outer wall of the spraying cylinder 4 is equidistantly provided with feeding ends. One end is fixedly connected with the same shunt pipe 3, and the feeding end of the feed pump 12 is connected to the inner wall of the shunt pipe 3 through a pipeline. The inner wall is equidistantly connected with a drain plate 22 by a hinge, and the drain plate 22 is centered on the feeding end of the spraying cylinder 4 to radiate to both ends. A connecting spring 23 is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com