Cutting device capable of achieving action of cutter and female die synchronously

A technology of cutting device and die, which is applied in the field of punching and processing parts, can solve the problems of high cost of punching gaps and long working cycle time, and achieve the effects of low cost, reduced moving time, and reduced action steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

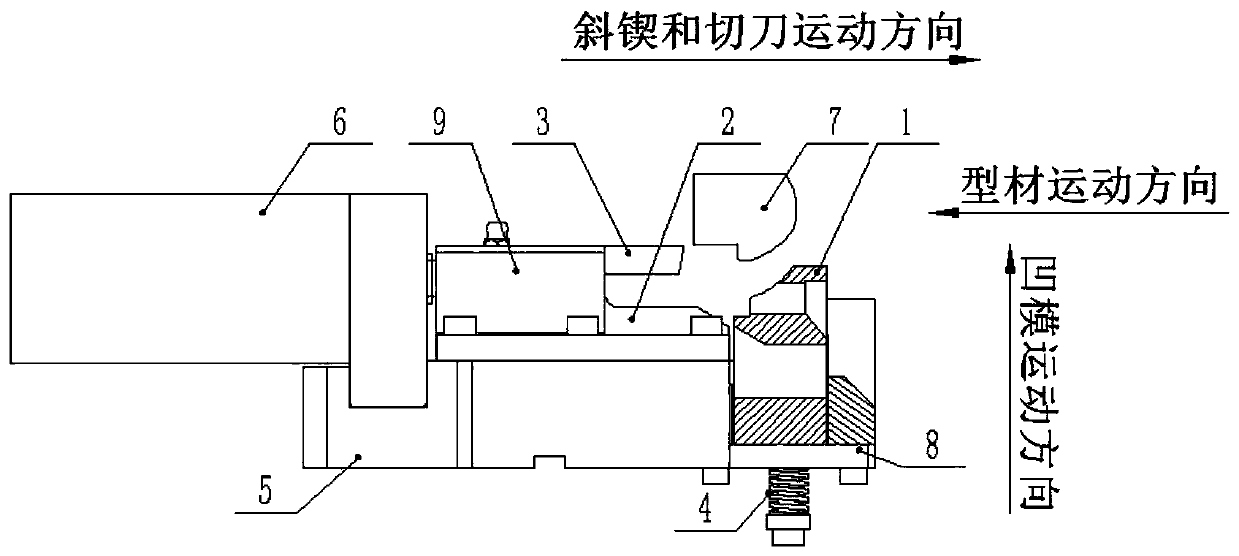

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0013] Such as figure 1 As shown, a cutting device that realizes the action of the cutter and the die at the same time can avoid the bending direction of the three-dimensional parts during work.

[0014] The cutting device comprises a base 5 and a telescoping device 6, the base 5 is provided with a connecting block 9, and the lower part of the connecting block 9 is slidably arranged on the base 5 through sliding parts such as slide rails.

[0015] The telescopic device 6 can be one of commonly used telescopic parts such as telescopic cylinders, telescopic oil cylinders, electric telescopic rods, etc. After the telescopic device 6 is started, it can drive the connecting block 9 to slide on the base 5, so that the connecting block 9 is close to or away from the three-dimensional bending The bend position of the part.

[0016] A cutter 3 and an active lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com