Hollow guide rail for guiding running direction of elevator

A hollow guide rail and elevator operation technology, which is applied in the field of elevator accessories, can solve the problems of tired installation workers and transport workers, high manufacturing costs, and high physical exertion, so as to reduce the number of vertical installations, improve area utilization, and increase The effect of cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

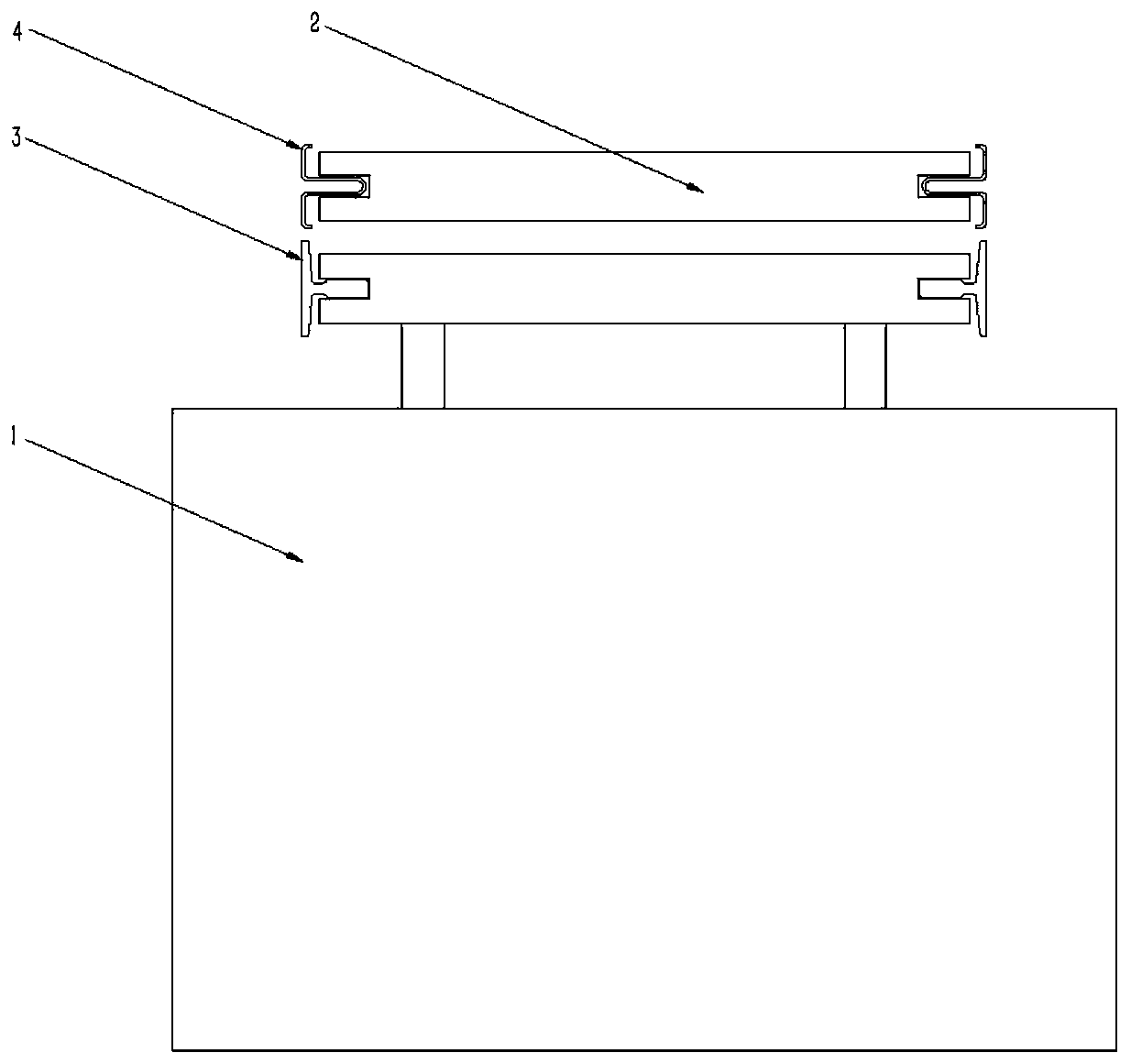

[0044] Such as Figure 4-13 As shown, a hollow guide rail oriented to the running direction of an elevator includes a hollow guide rail 4 formed by integral bending / rolling. The elevator car 1 and counterweight 2 are installed on the integrated hollow guide rail 4, and the hollow guide rail 4 is pressed The guide plate 5 is installed on the guide rail bracket 13, and the guide rail bracket 13 is installed on the wall. After the hollow guide rail 4 is bent / rolled and welded, it is formed to be connected with the counterweight guide shoe 9 on the counterweight 2 and the car on the car 1 respectively. The position of the car guide shoe 10 corresponds to the counterweight running guide groove 6 and the car running guide surface 7, and the hollow guide rail 4 guides the car 1 and the counterweight 2 in the running direction at the same time, and the car 1 and the counterweight 2. Under the guidance of the hollow guide rail 4, they move in opposite directions. Specifically, the car ...

Embodiment 2

[0048] Such as Figure 5-14 As shown, a hollow guide rail oriented to the running direction of an elevator includes a hollow guide rail 4 formed by integral bending / rolling and welding. The car 1 and counterweight 2 of the elevator are installed on the hollow guide rail 4, and the hollow guide rail 4 passes through the guide rail The bracket 13 is installed on the wall, and the hollow guide rail 4 is bent / rolled to form a counterweight running guide that corresponds to and cooperates with the counterweight guide shoe 9 on the counterweight 2 and the car guide shoe 10 on the car 1 respectively. The slot 6 and the car running guide surface 7, the counterweight running guide slot 6 is U-shaped, and the hollow guide rail 4 guides the car 1 and the counterweight 2 in the running direction at the same time, and the car 1 passes the car guide shoe 10 in the The car moves up and down under the guiding action of the running guide surface 7, and the counterweight 2 moves up and down und...

Embodiment 3

[0055] Such as Figure 5-13 with Figure 15 As shown, a hollow guide rail oriented to the running direction of an elevator includes a hollow guide rail 4 formed by integral bending / rolling and welding. The car 1 and counterweight 2 of the elevator are installed on the hollow guide rail 4, and the hollow guide rail 4 passes through the guide rail The bracket 13 is installed on the wall, and the hollow guide rail 4 is bent / rolled to form a counterweight running guide that corresponds to and cooperates with the counterweight guide shoe 9 on the counterweight 2 and the car guide shoe 10 on the car 1 respectively. The slot 6 and the car running guide surface 7, the counterweight running guide slot 6 is U-shaped, and the hollow guide rail 4 guides the car 1 and the counterweight 2 in the running direction at the same time, and the car 1 passes the car guide shoe 10 in the The car moves up and down under the guiding action of the running guide surface 7, and the counterweight 2 move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com