X-ray inspection method for the quality of vertical reinforcement connection between layers of double-sided laminated shear walls

A technology of superimposed shear walls and vertical steel bars, applied in the direction of measuring devices, using wave/particle radiation, and using radiation for material analysis, can solve the problems of many times of shooting, increased detection cost, low efficiency, etc., and achieve detection The results are accurate, the cost of inspection is saved, and the number of shots is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

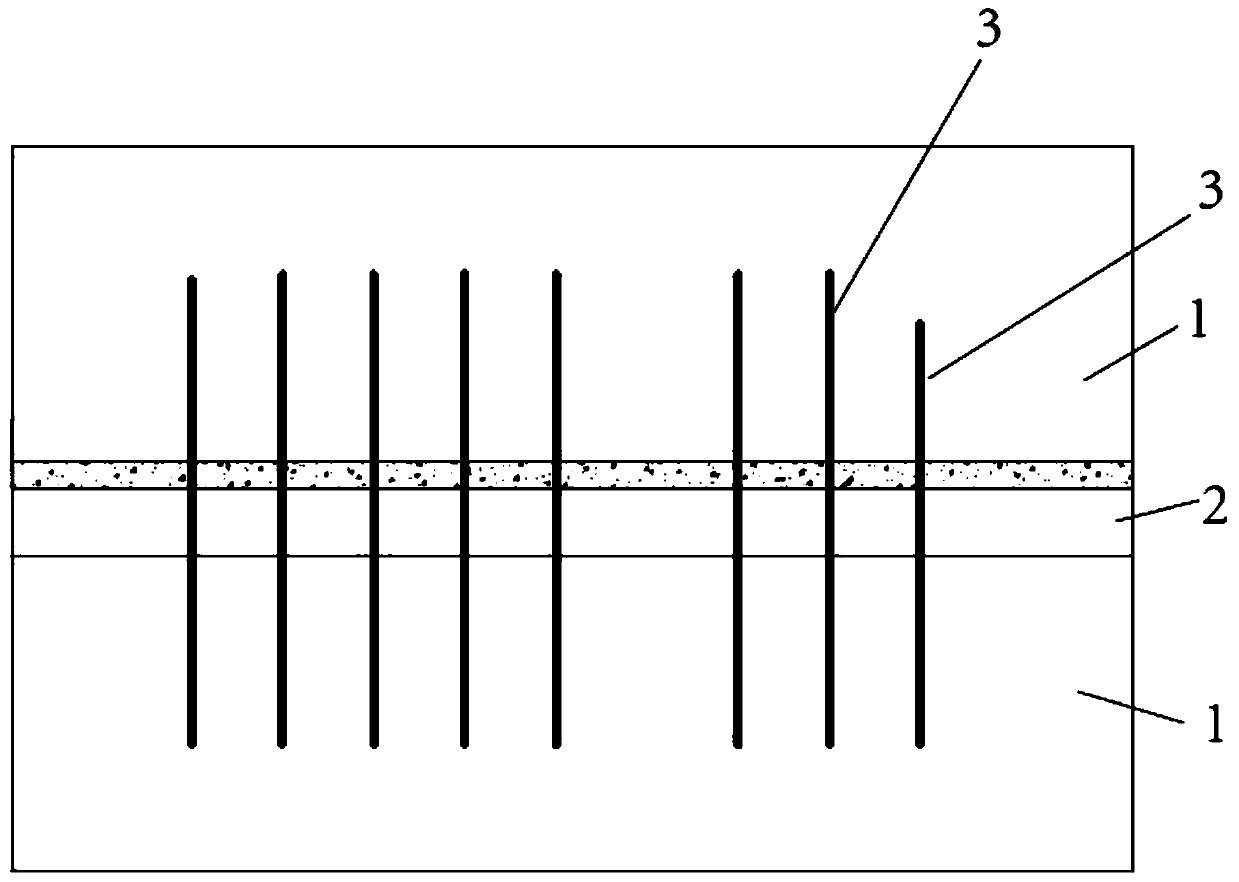

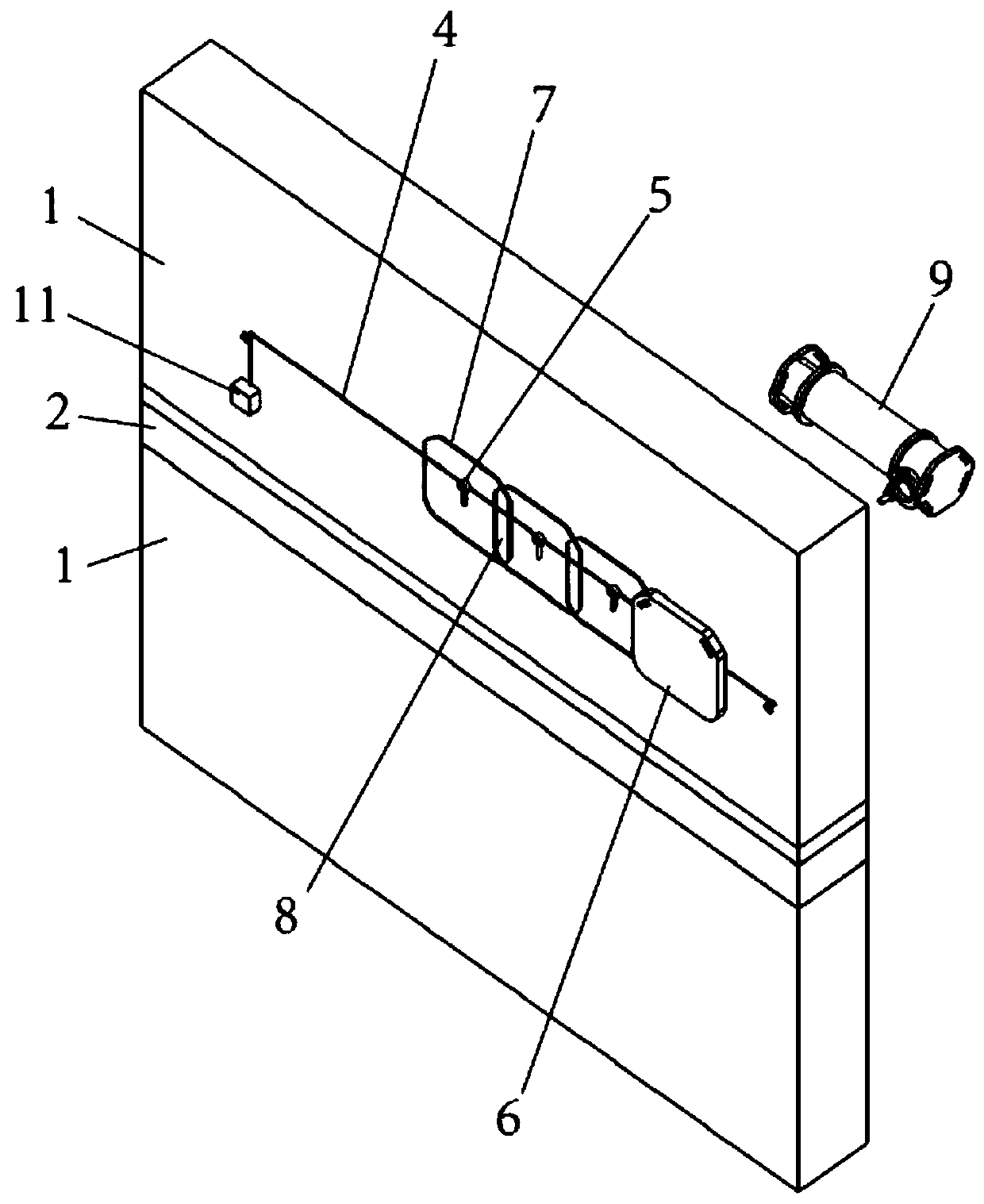

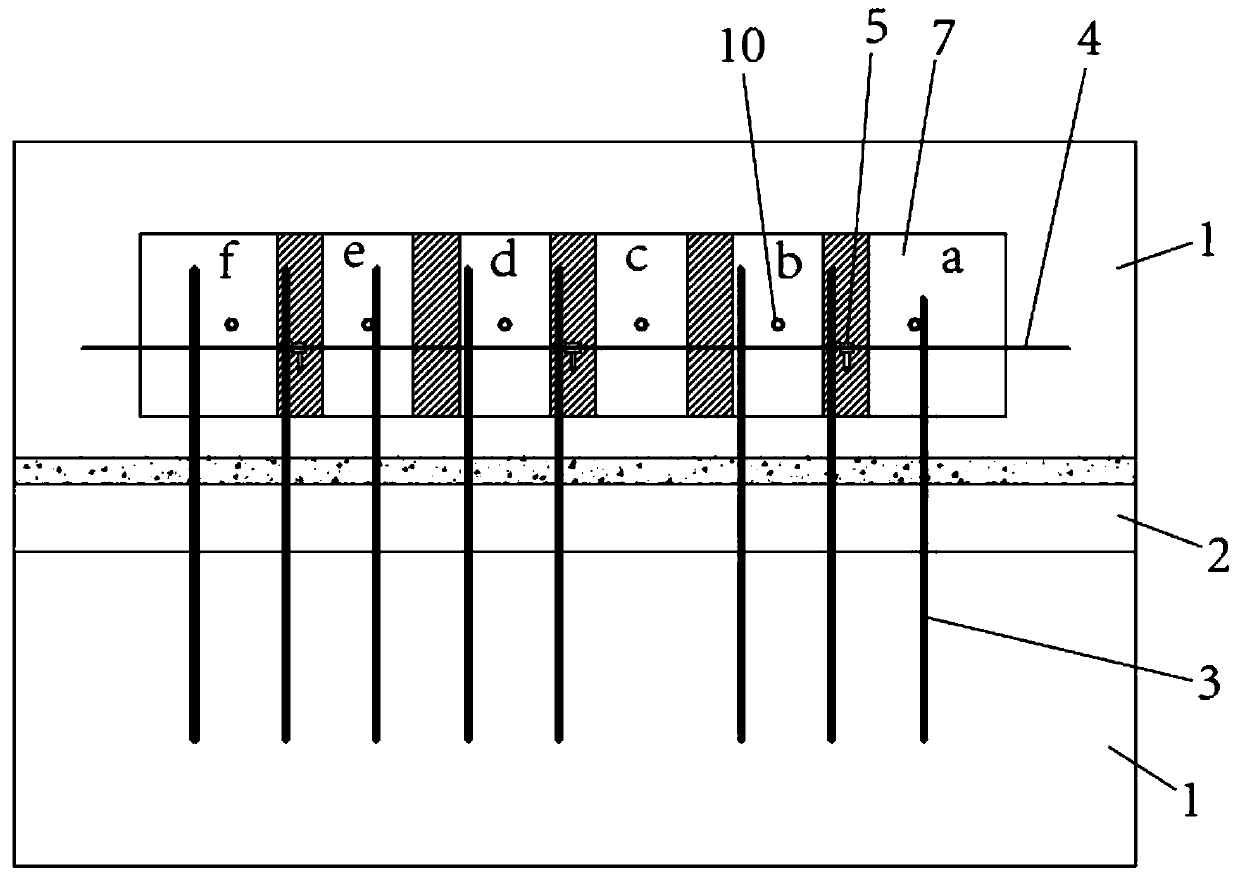

[0046] An embodiment of the X-ray detection method for the connection quality of the vertical reinforcement between layers of a double-sided laminated shear wall of the present invention, wherein the vertical connection reinforcement 3 in this embodiment uses HRB400 hot-rolled ribbed reinforcement, and the diameter of the reinforcement is 12mm , the seismic grade is calculated as grade 3, and the seismic anchorage length is l aE is 34d, the calculation can be l aE =408mm, the design anchorage length of connecting steel bar is 1.2l aE =490mm; one end of the vertical connecting steel bar 3 extends into the double-sided laminated shear wall 1 of the adjacent lower floor, and the oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com