Manual making method of spiral lining plate model

A production method and model technology, which is applied to the jointing of wooden veneers, manufacturing tools, casting and molding equipment, etc., can solve the problems of difficult measurement of size, high production cost, and difficult production, so as to achieve high production efficiency and low production cost. Low, easy to find any size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

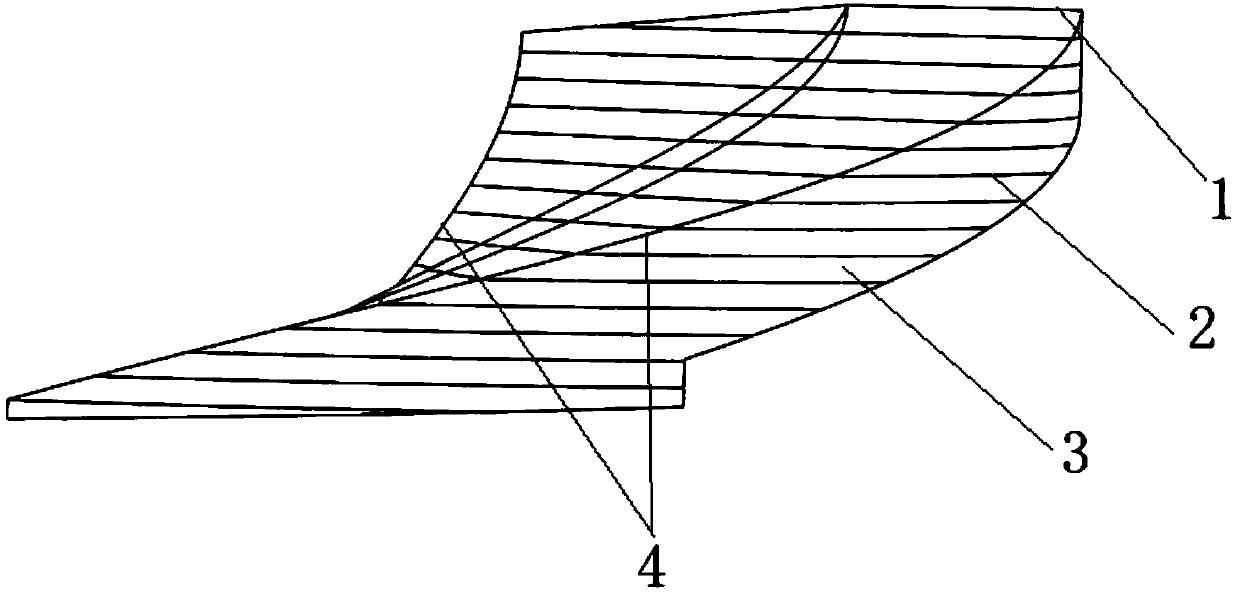

[0026] like figure 1 Shown, a kind of manual manufacturing method of spiral liner model of the present invention comprises the following steps:

[0027] (1) Firstly, use 3D software for modeling and section drawing, specifically:

[0028] A. Use 3D software to make a three-dimensional view of the spiral lining casting; according to the set casting scale, enlarge the three-dimensional drawing of the spiral lining casting to obtain a three-dimensional drawing of the spiral lining model;

[0029] B. Modeling is based on the spiral lining model, and the top-view reference plane passing through the apex of the spiral lining model is set as the base reference plane 1; according to the height of the three-dimensional view of the spiral lining model, the model i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com