High-resolution odor detection sensor

An odor detection and high-resolution technology, which is applied in the analysis of gas mixtures, the structure details of gas analyzers, instruments, etc., can solve the problems of single detection method, large difference in odor detection, large detection error, etc., and achieve the goal of improving odor recognition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

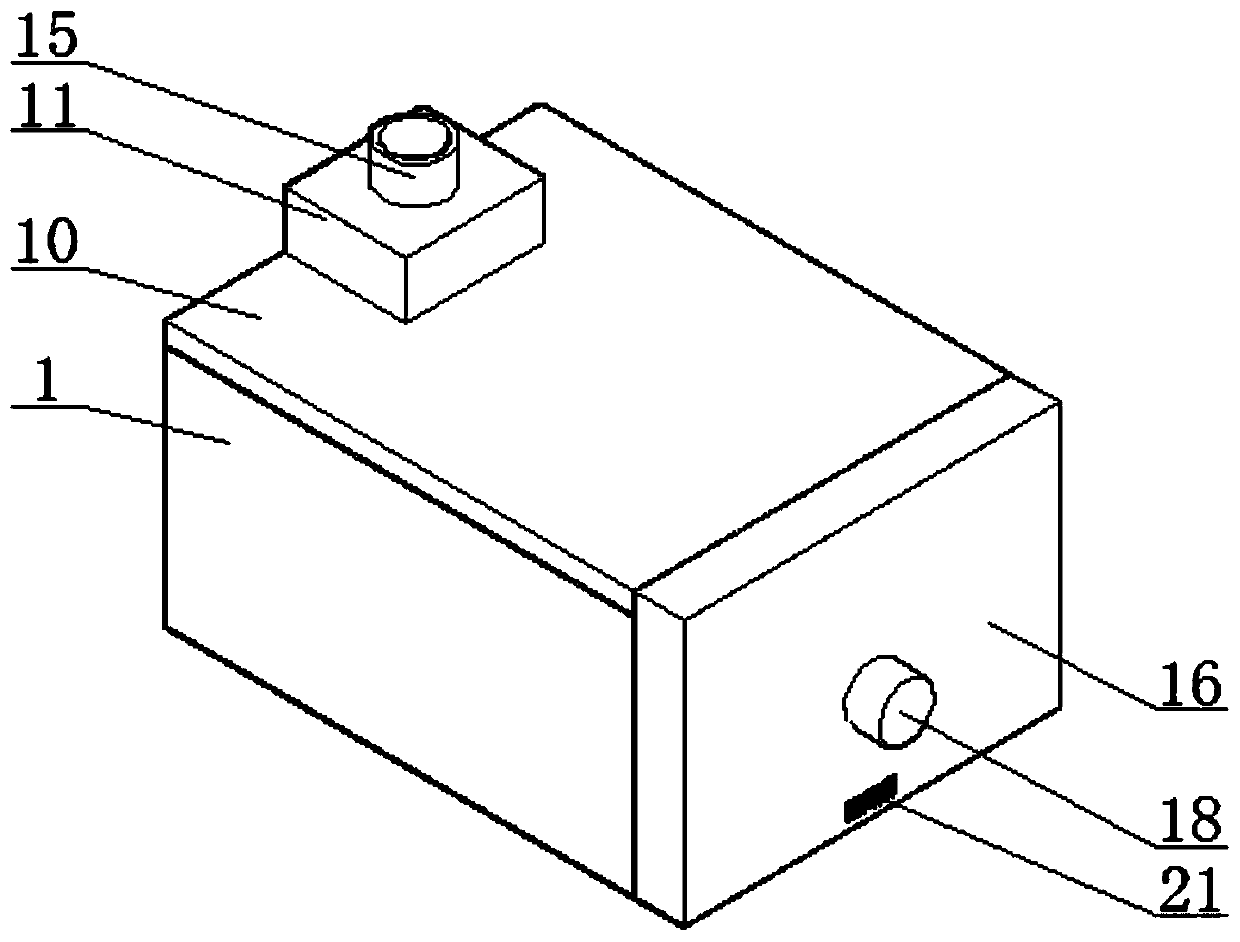

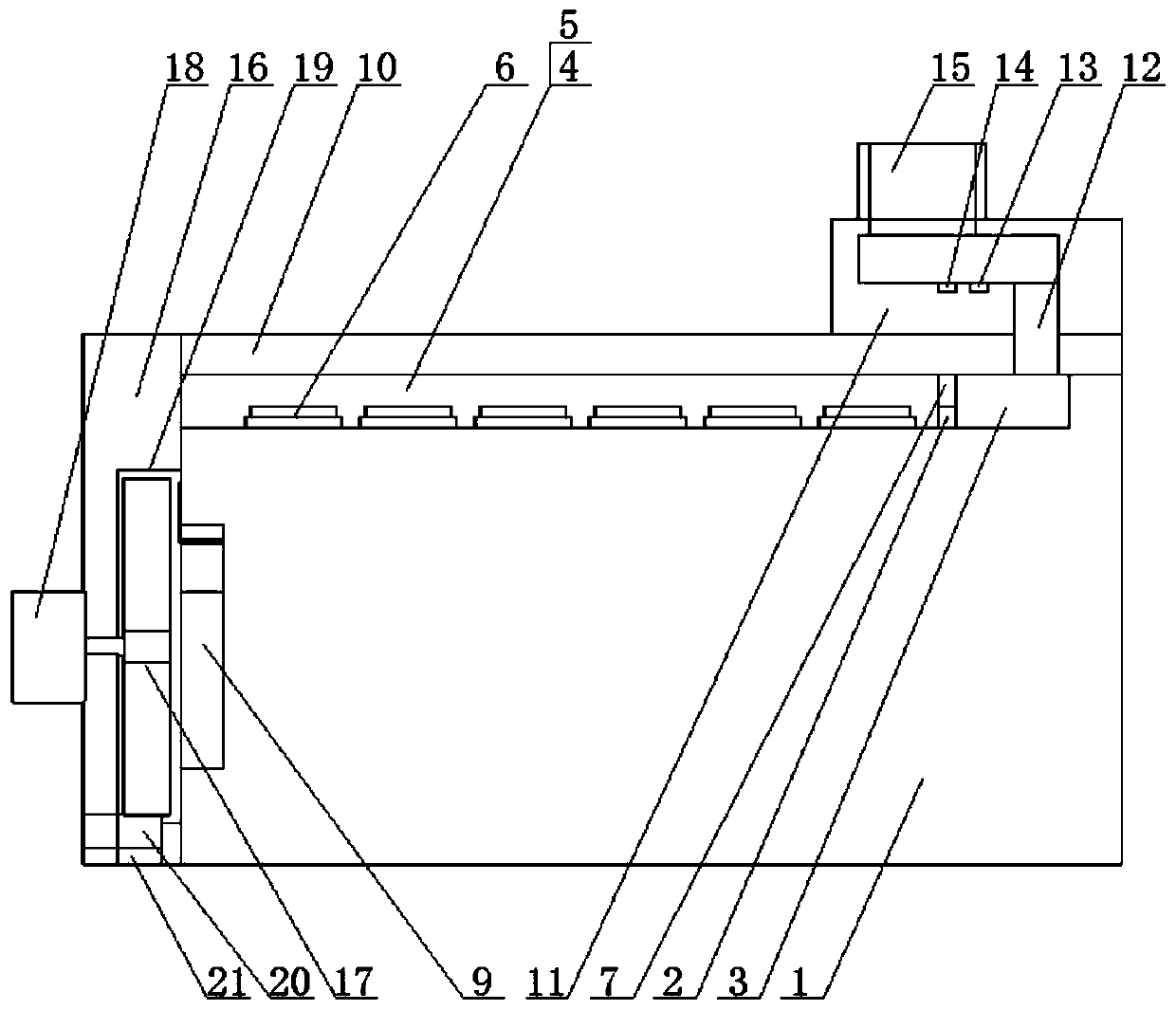

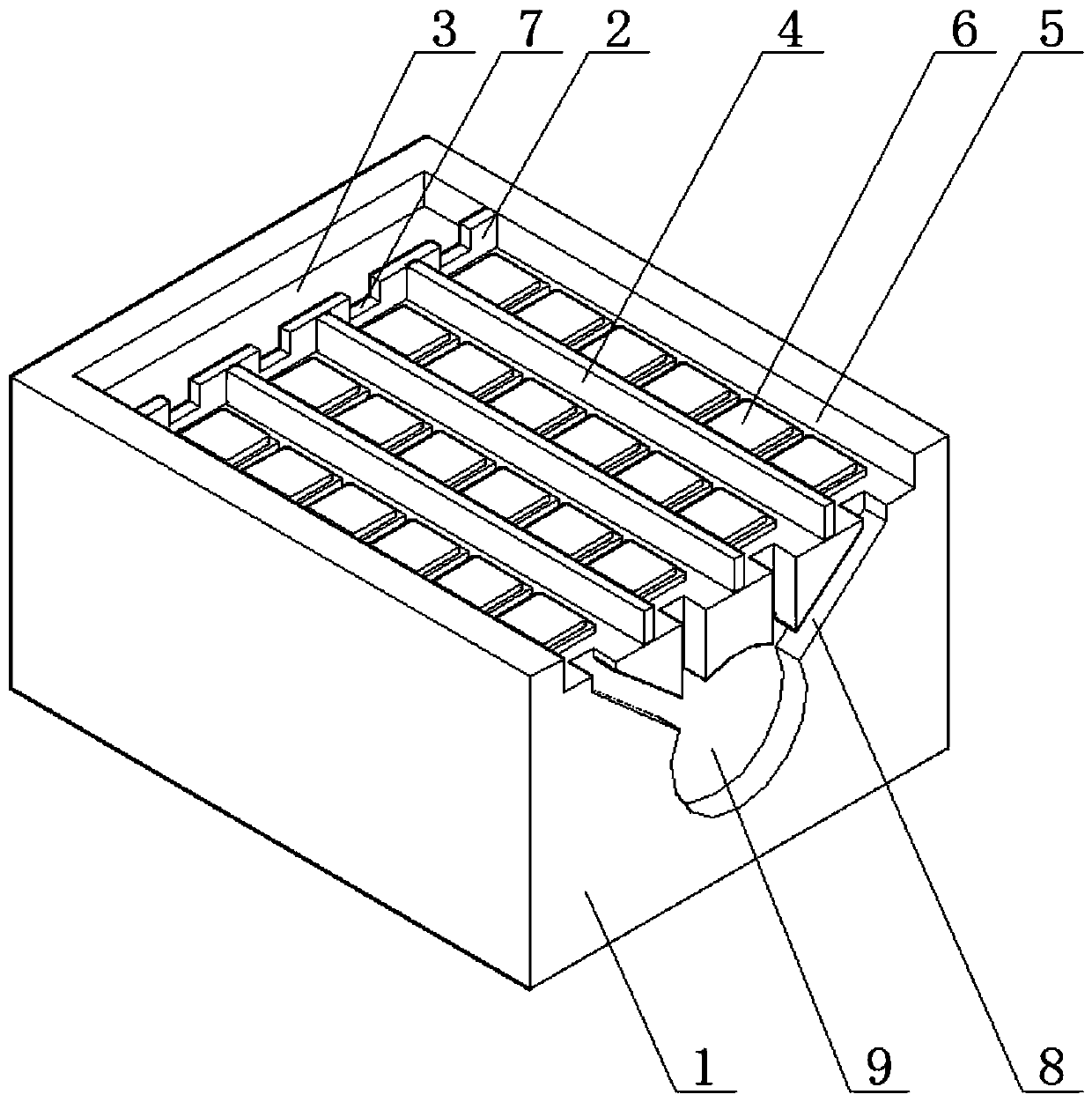

[0019] see Figure 1-3 , a high-resolution odor detection sensor, comprising a sensor body 1, the upper end of the sensor body 1 is provided with an installation groove for installing the odor detection unit, one end of the installation groove is fixedly connected with a transverse partition 2, and the transverse partition 2 connects the installation groove A gas transition zone 3 is divided to detect the transition of gas, and a plurality of longitudinal diaphragms 4 are fixedly connected in the installation groove on one side of the diaphragm 2, the height of the diaphragm 2 is consistent with the height of the diaphragm 4 and Both are the same as the groove depth of the installation groove, and multiple mediastinum plates 4 divide the installation groove into a plurality of odor detection belts 5, and the bottom of each odor detection belt 5 is fixedly connected with a plurality of odor sensing units 6 for odor collection , the diaphragm 2 corresponding to each odor detecti...

Embodiment 2

[0022] In the present invention, a rubber sealing layer is provided between the upper end surface of the sensor body 1, the diaphragm 2 and the medial diaphragm 4, and the bottom surface of the packaging cover 10, to prevent the entry of external air and the gas interaction between each odor detection belt 5. interference.

[0023] The odor sensing unit 6 is one or more of a metal oxide semiconductor sensor, a conductive polymer sensor, a mass sensor, and an optical fiber gas sensor.

[0024] A data processing unit is arranged inside the sensor body 1, and the data processing unit is connected with the odor sensing unit 6, the temperature sensor 13, and the humidity sensor 14 through the data line, and is used to obtain the electrical characteristics obtained by interacting the odor sensing unit 6 with the detected gas. Mapping, and thus visual recognition.

[0025] The exhaust device comprises an exhaust shell 16, an exhaust fan 17, and an exhaust motor 18. The exhaust shell...

Embodiment 3

[0029] In this example, the odor sensing unit 6 in each odor detection zone 5 is a group of detection signal units, and a plurality of odor detection zones 5 can carry out multiple odor detections to the detection gas at the same time, each odor detection zone 5 The sensors used in the odor sensing unit 6 are different, and the odor sensing unit 6 of one group of detection signal units is a metal oxide semiconductor sensor, and the odor sensing unit 6 of another group of detection signal units is a conductive polymer sensor , the odor sensing unit 6 of the next group of detection signal units is set in sequence for quality sensors and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com