Thermostatic cartridge for regulating cold and hot fluids to be mixed

A thermostatic valve core, mixed fluid technology, applied in control/regulation systems, temperature control without auxiliary power, multi-port valves, etc., can solve problems such as increasing total assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

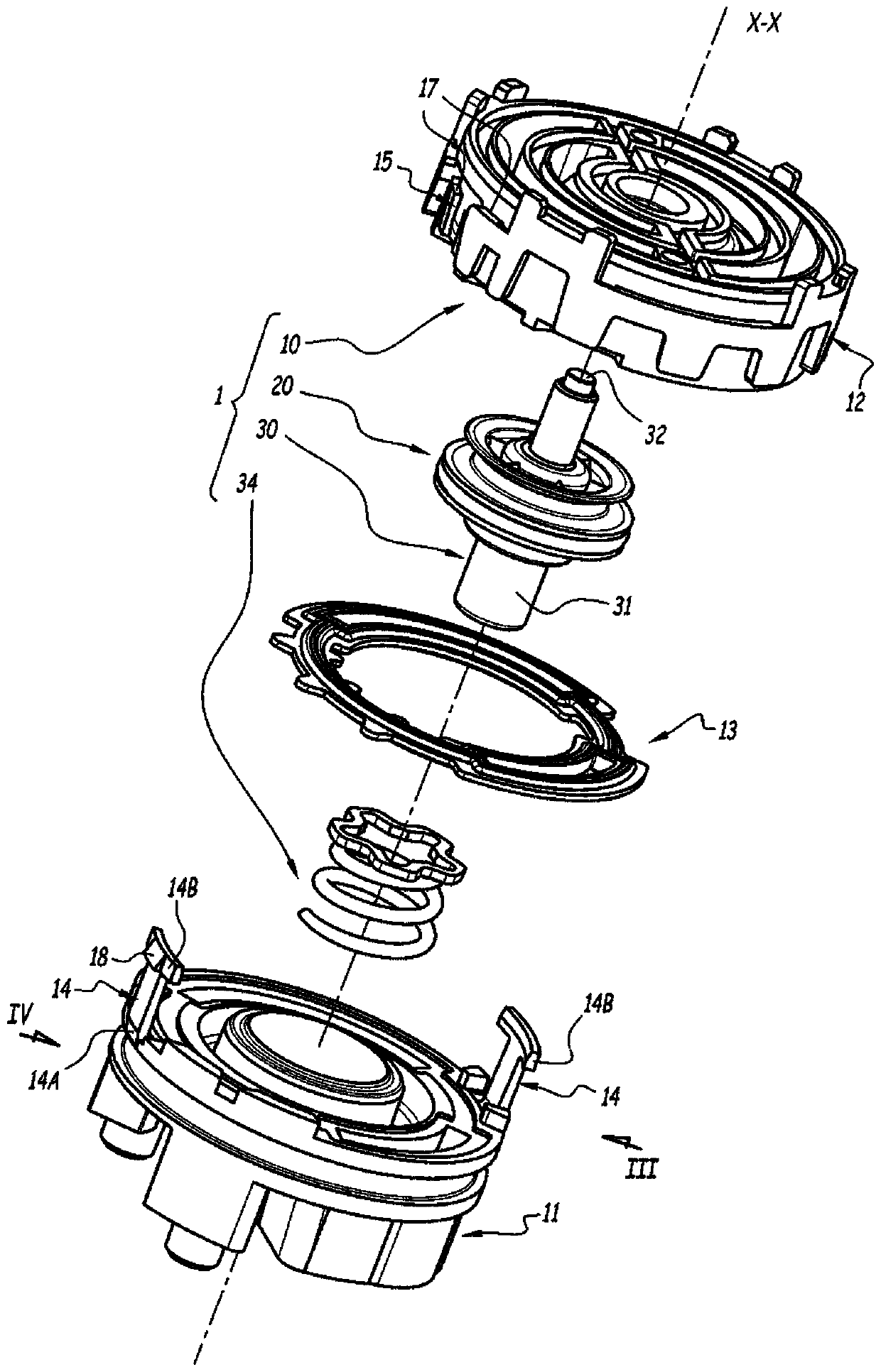

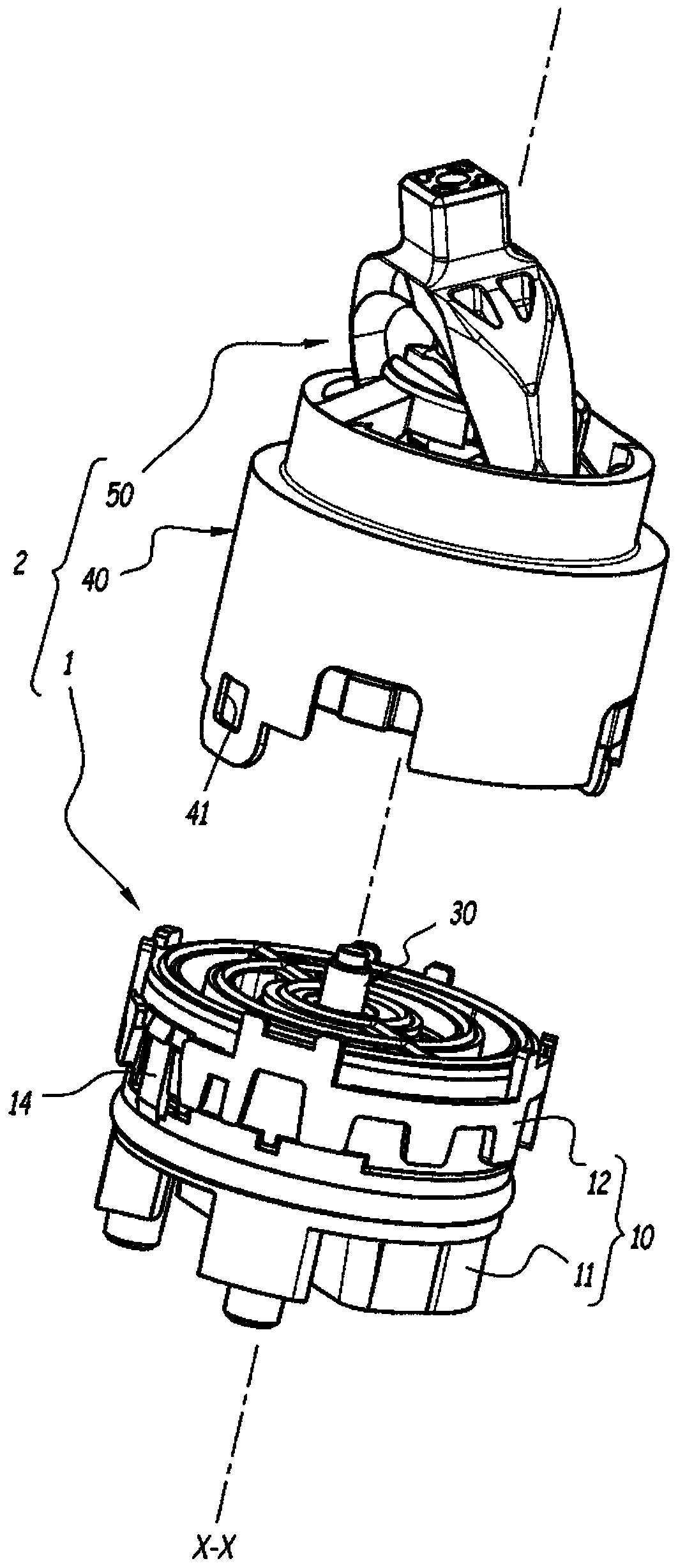

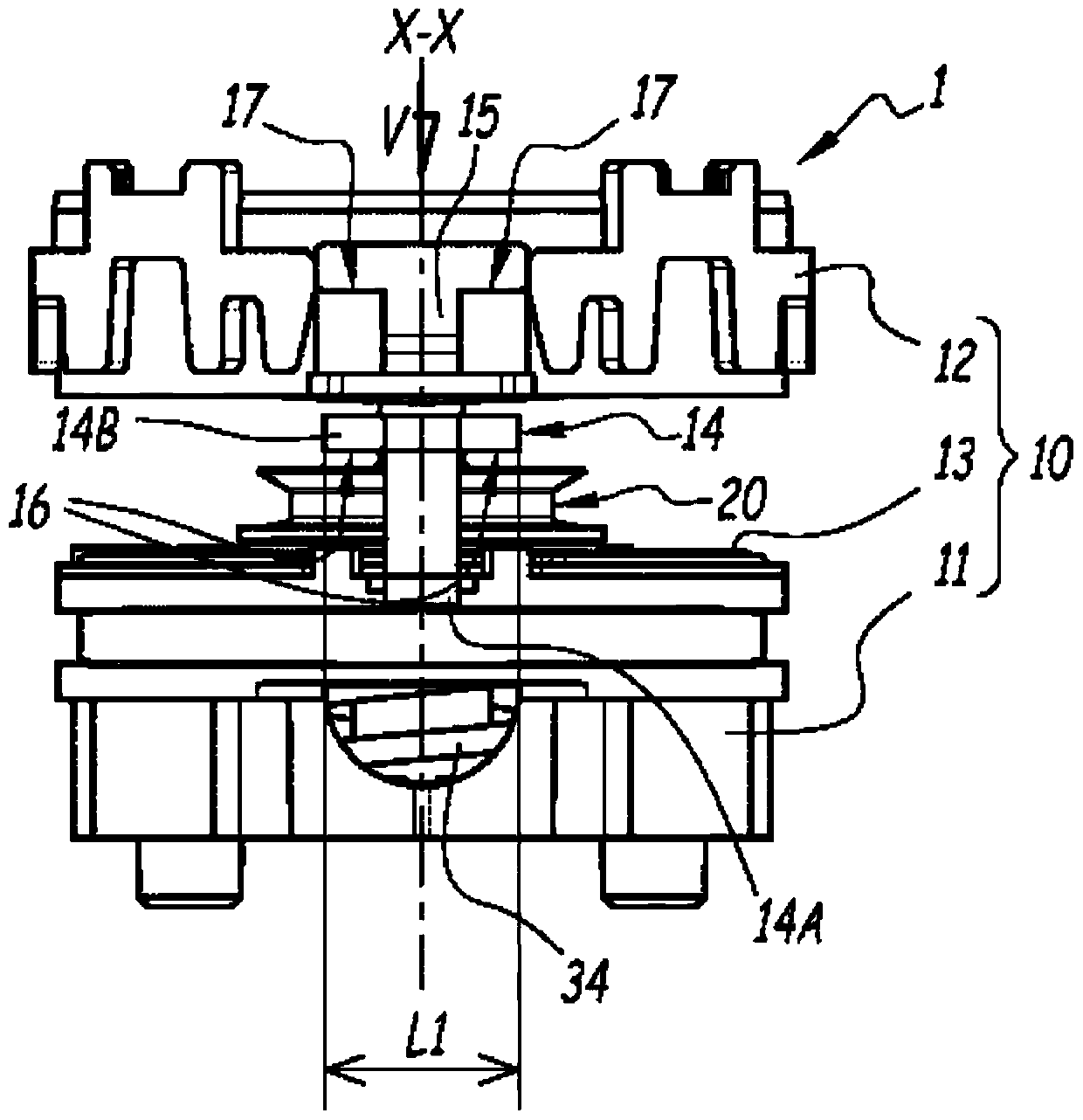

[0019] figure 1 as well as Figure 3 to Figure 7 Only one assembly 1 is shown, which belongs to figure 2 , Figure 8 and Figure 9 The thermostatic spool 2 shown as a whole in . The thermostatic spool 2 is designed to be equipped with a mixing valve which is not in the figure 2 shown in and intended to supply hot and cold water. More generally, the thermostatic cartridge 2 is designed to be equipped with a sanitary facility delivering a fluid obtained by mixing hot and cold fluids in the cartridge.

[0020] Assembly 1 is centered on the geometric axis X-X. For convenience, the following description is oriented relative to this axis X-X, where the terms "upper", "top", etc. are considered to correspond to Figure 1 to Figure 4 as well as Figure 6 to Figure 9 The axial direction of the upper part of , while the terms "lower", "lower", etc. correspond to the axial direction in the opposite direction. Therefore, within the thermostatic valve core 2, the assembly 1 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com