Patents

Literature

41results about How to "Limited time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

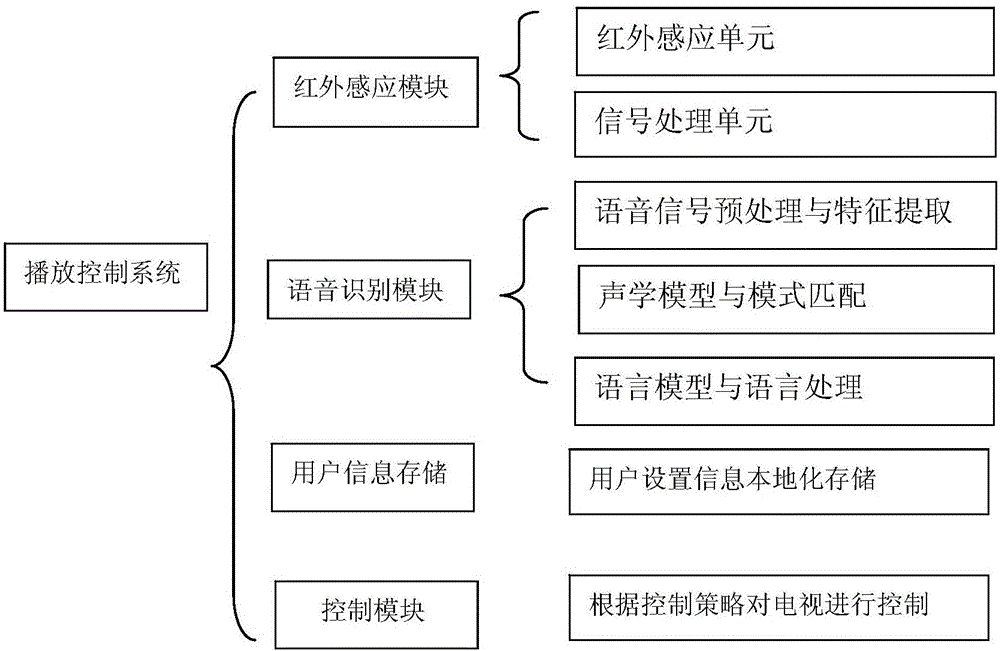

Intelligent television playback control system and method

InactiveCN106454515ALimited timeProtect physical and mental healthSelective content distributionMental healthControl function

The present invention relates to the field of intelligent televisions, and discloses an intelligent television playback control system and method. A playback control function of the intelligent television in a kid mode is provided for parents and can effectively protect physical and mental health of kids. The method comprises a first step that after a user turns on the intelligent television, it is identified and determined that a current user is a kid user or an adult user according to voice, if the current user is the kid user, a second step is performed, and if the current user is the adult user, the intelligent television is used normally; and the second step that the intelligent television enters the kid mode, and enables a function of protecting the kid in watching TV according to configuration information stored in a user information storage module and a determining result of an infrared sensing module.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

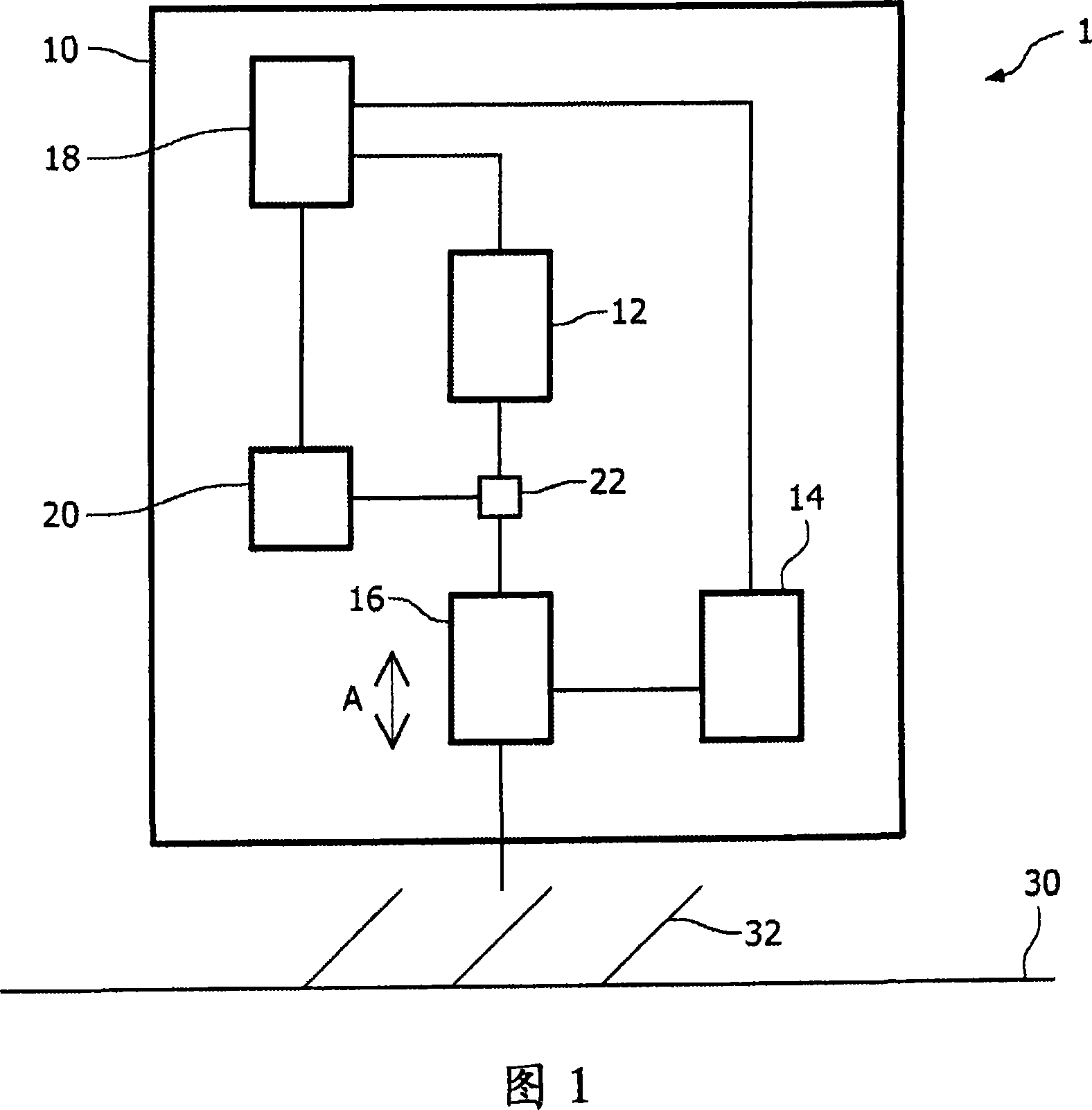

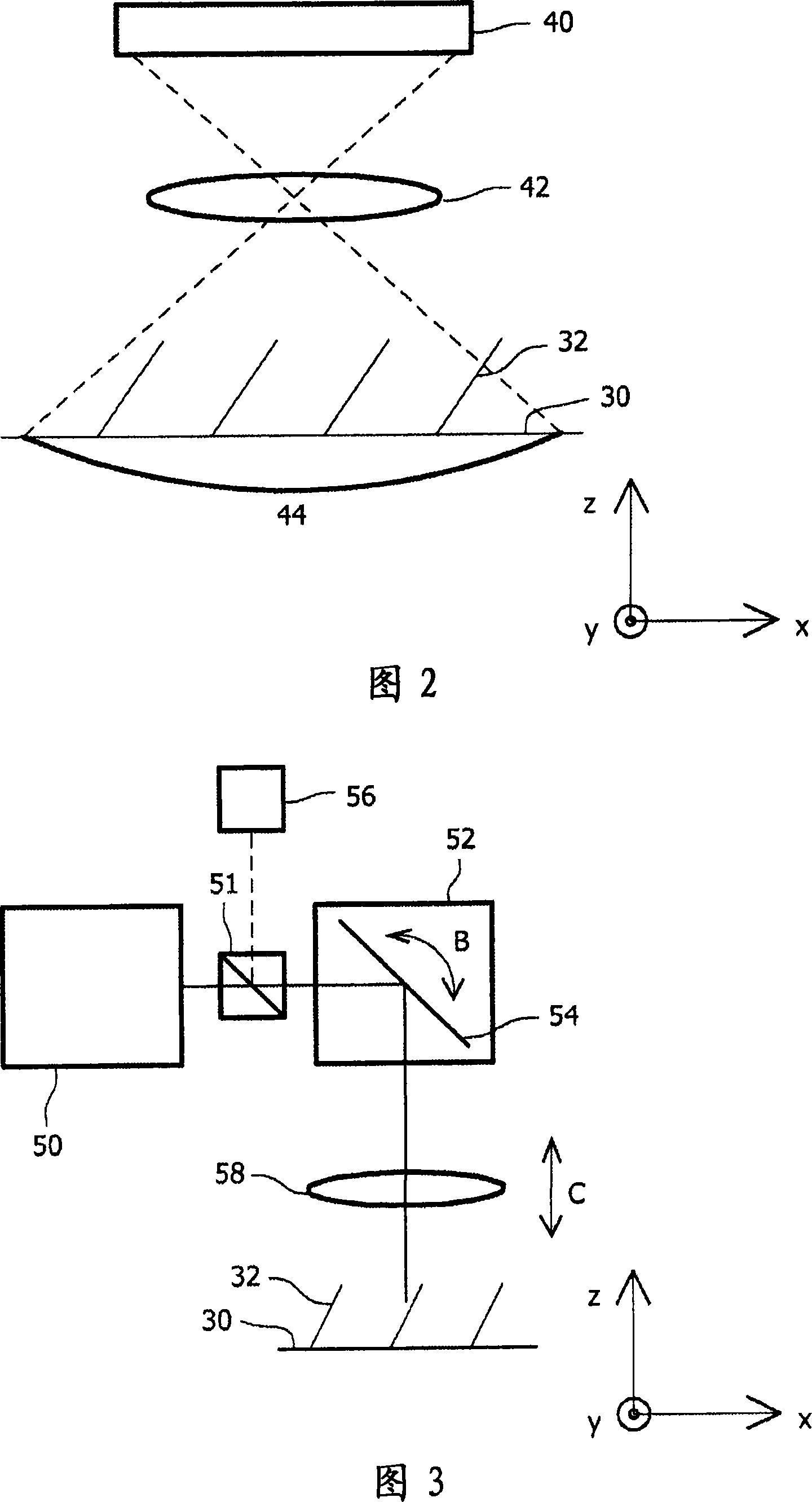

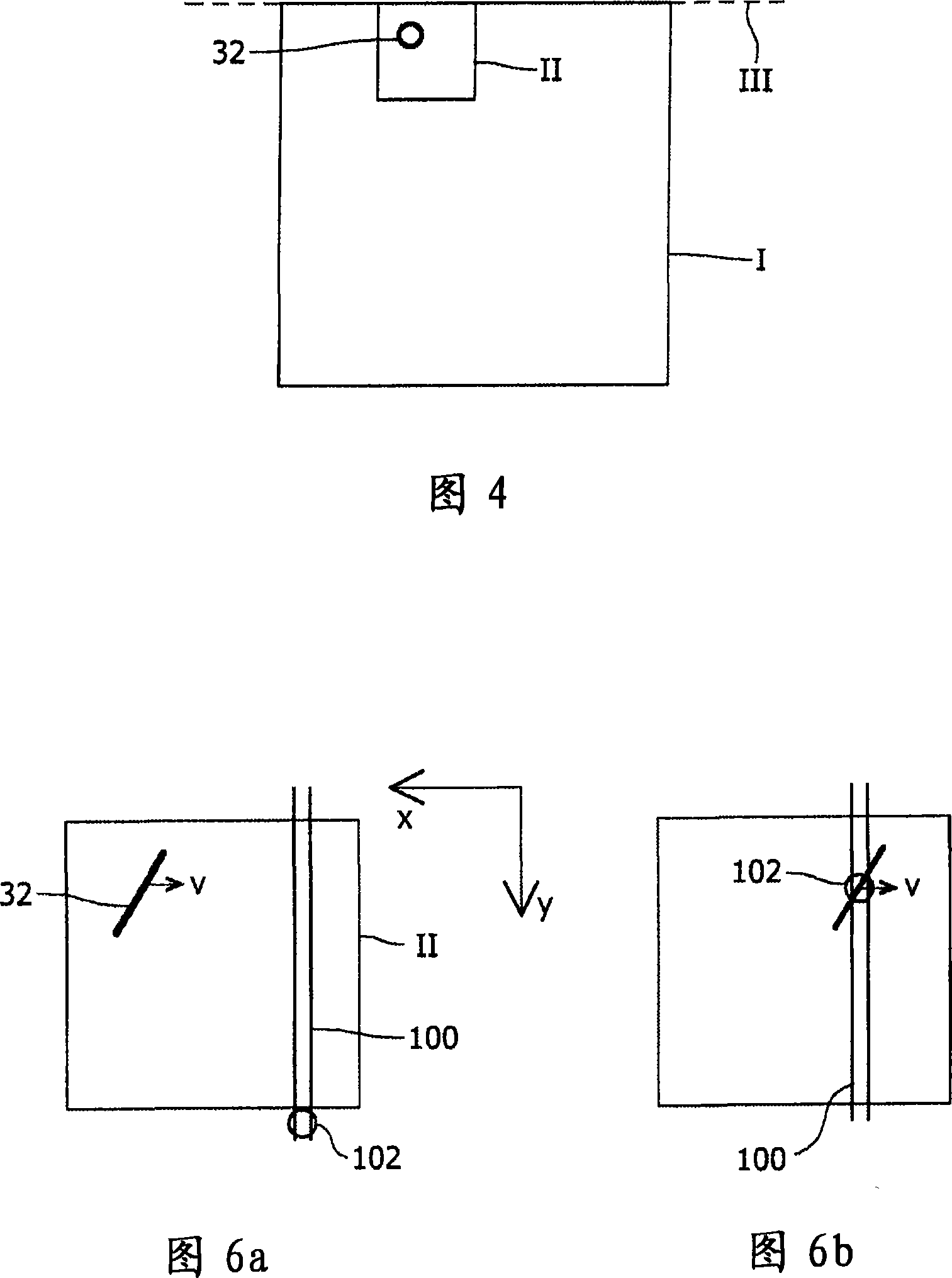

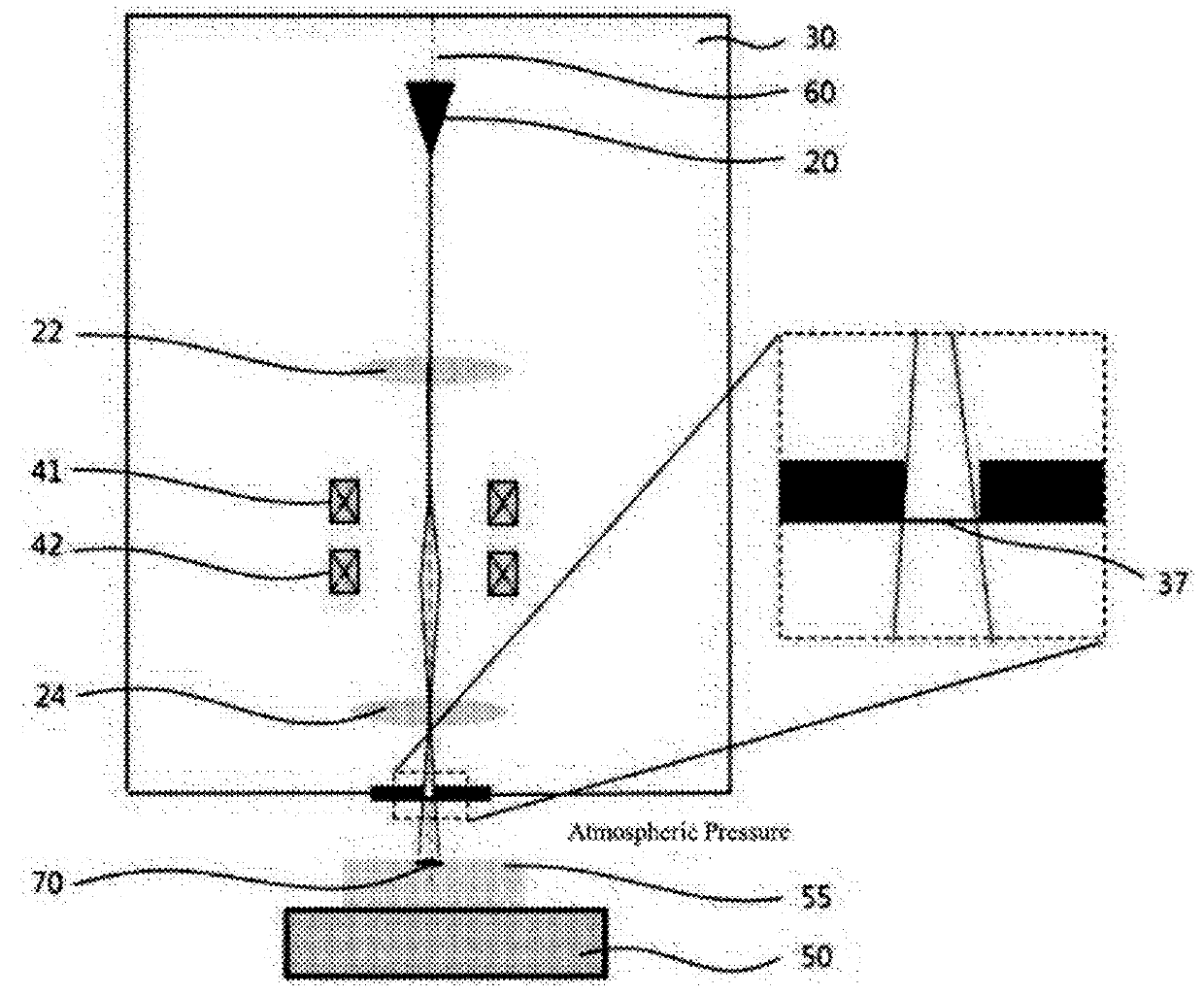

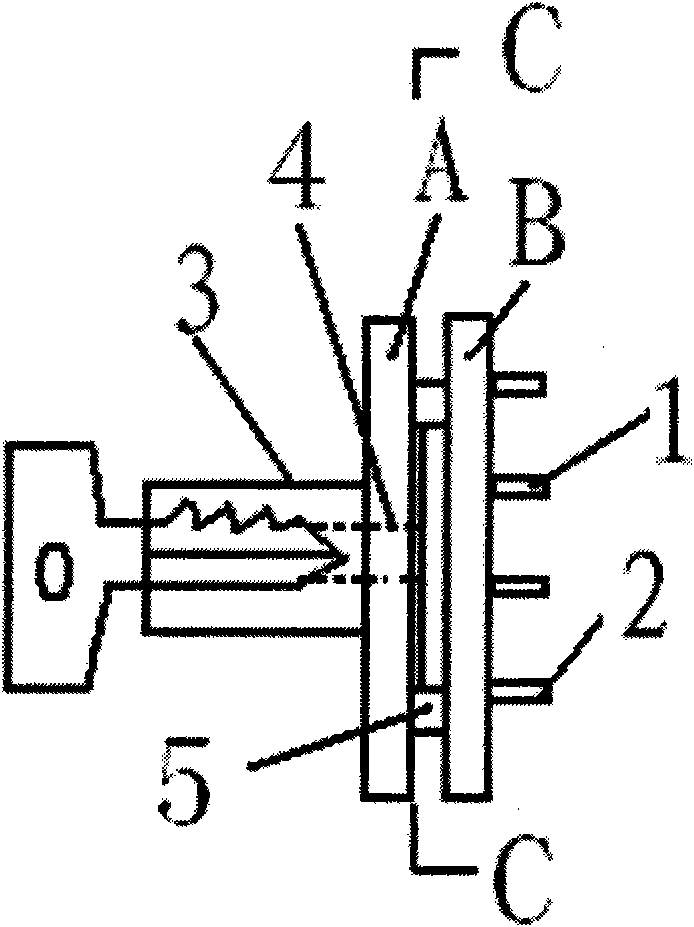

Hair removing system

The invention relates to a system and method for removing hair. The system comprises a hair detection device and a hair-removing device (20). Since 3D information on hairs (32) is required, but due to the very dispersed presence of, e.g., human hairs (32) on skin (30), known detection devices are too slow, the invention provides a combination of two image sensors. A first image sensor (12) produces a first image, based on which a selected part is imaged with a second image sensor (14) that provides the required 3D position information with which the hair-removing device (20) can remove the hair. Thus, optimum use may be made of both fast but less accurate image sensors, such as (2D) CCDs or CMOS sensors, and accurate but slow sensors such as 3D scanning sensors.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

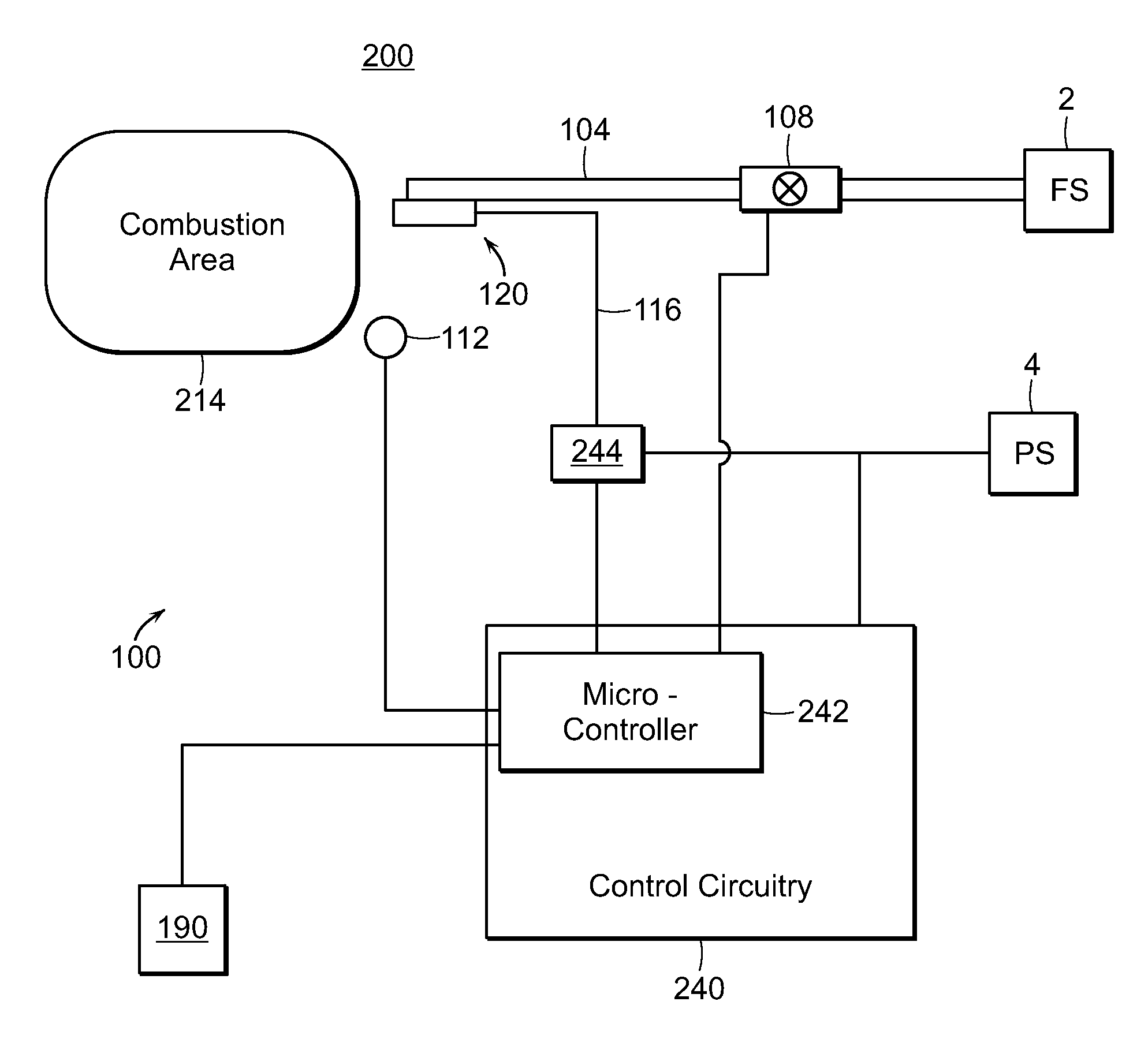

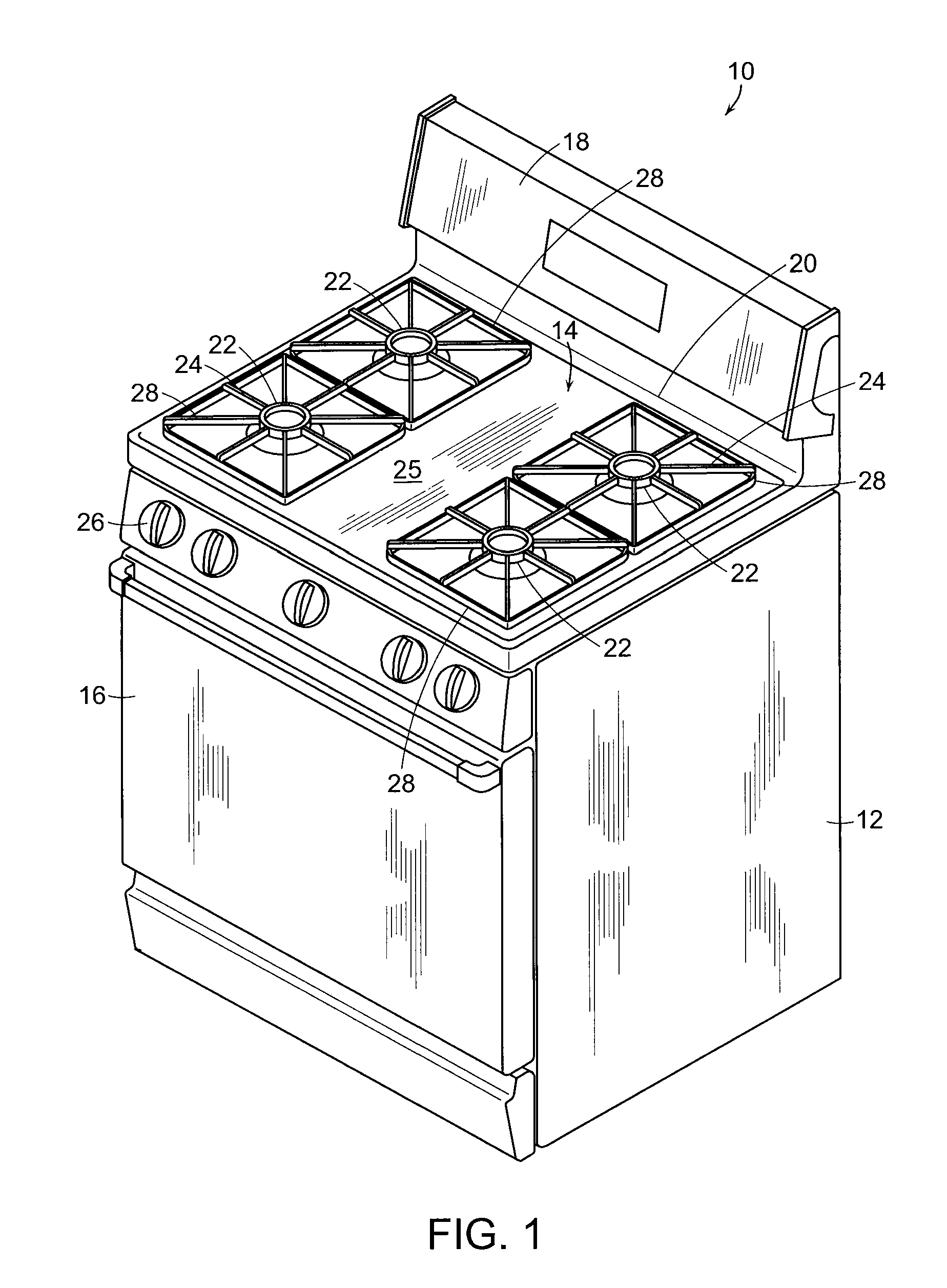

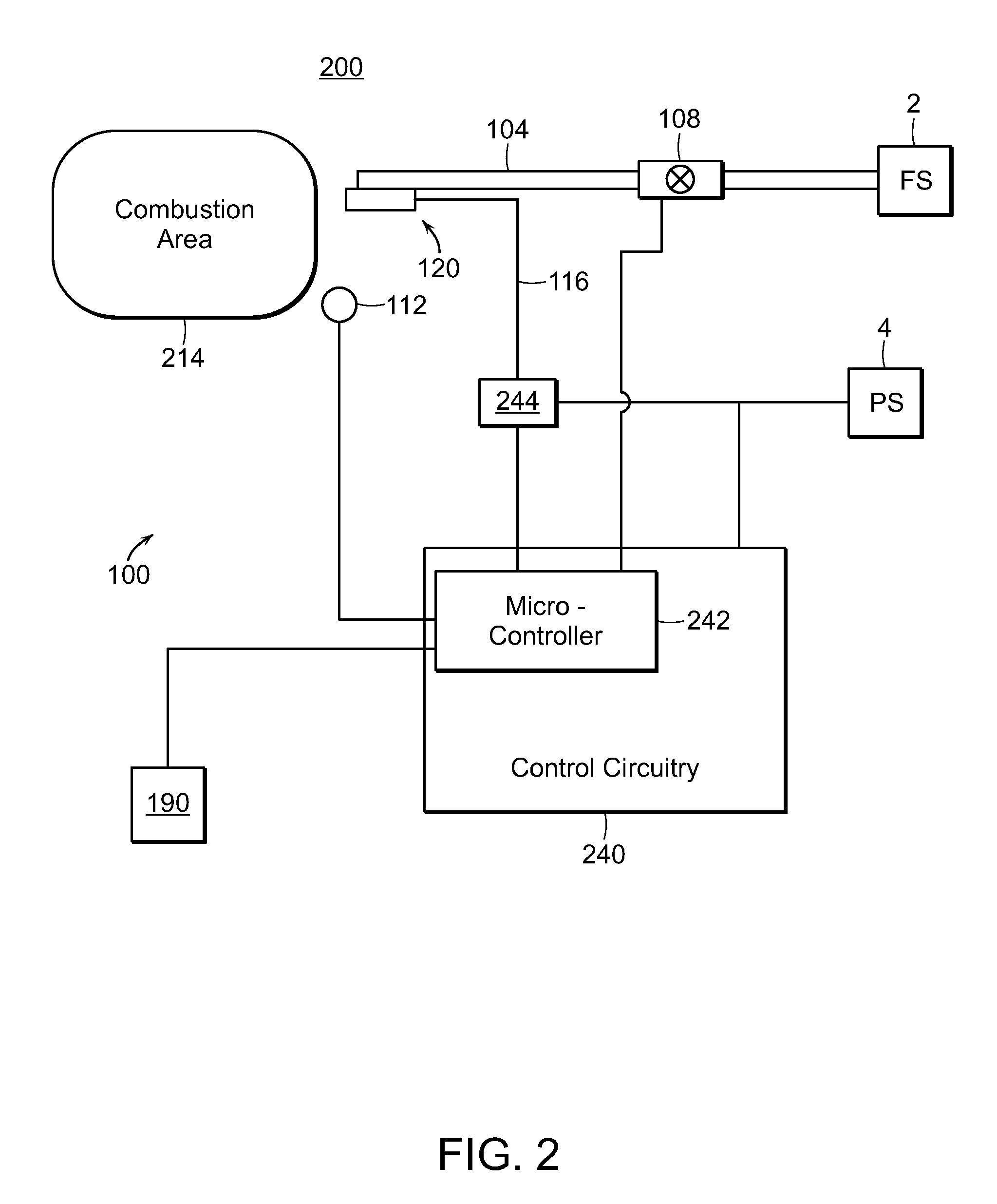

Ignition System Having Control Circuit With Learning Capabilities and Devices and Methods Related Thereto

InactiveUS20110264269A1Limited timeEliminate flowSampled-variable control systemsDomestic stoves or rangesMaterial systemSoftware

Featured is an ignition system using miniaturized hot surface igniters of various types, configurations, and material systems. The ignition system includes an electronic microprocessor on which a software program is executed so as to control the operation of an igniter and all functions of the ignition system. The software program evaluates performance characteristics relating to operation of the igniter. Additionally, the software program determines operation parameters and characteristics for energizing the igniter when it determines that the operation parameters and characteristics for energizing should be updated or revised.

Owner:CERAMTEC

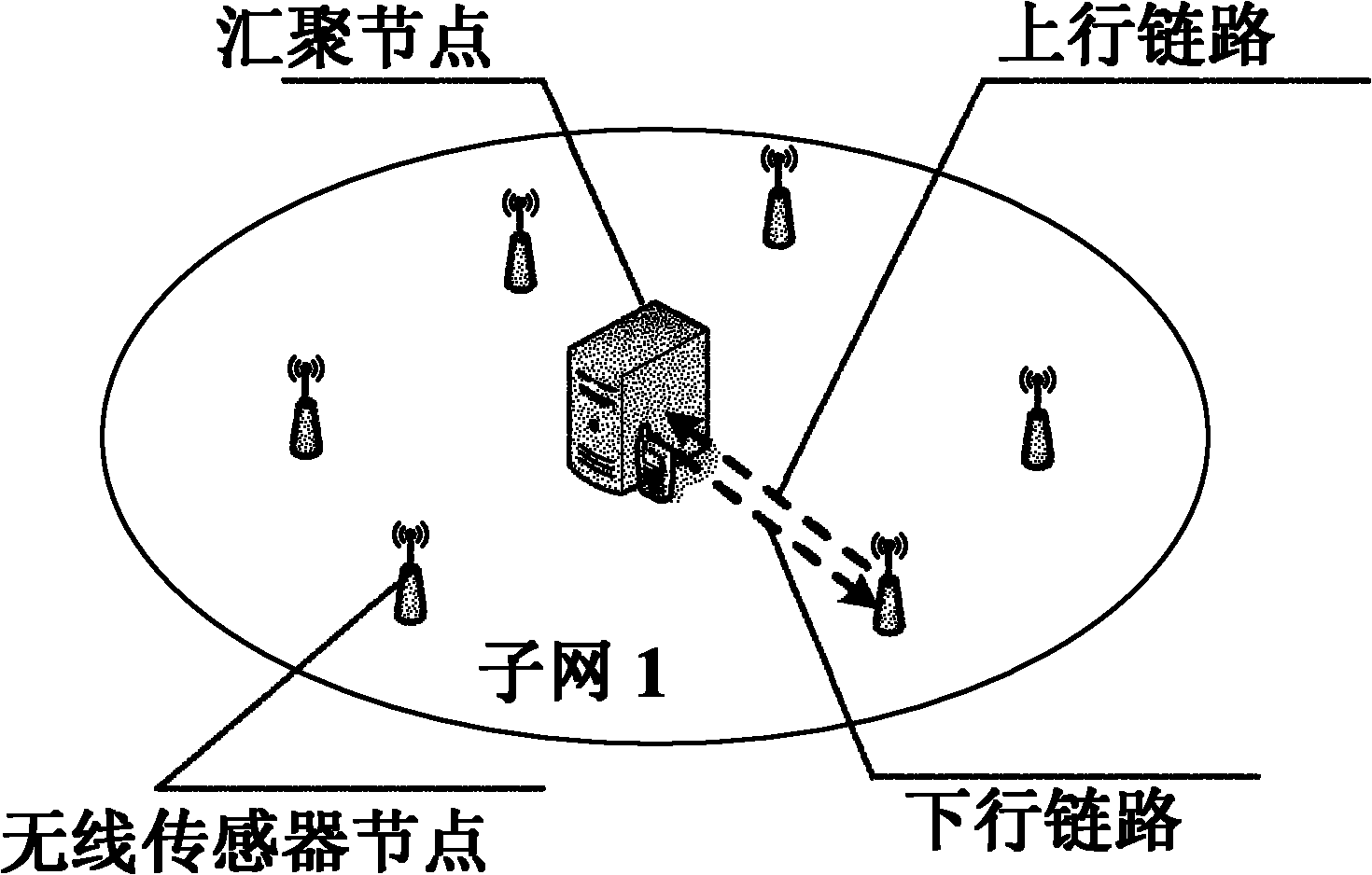

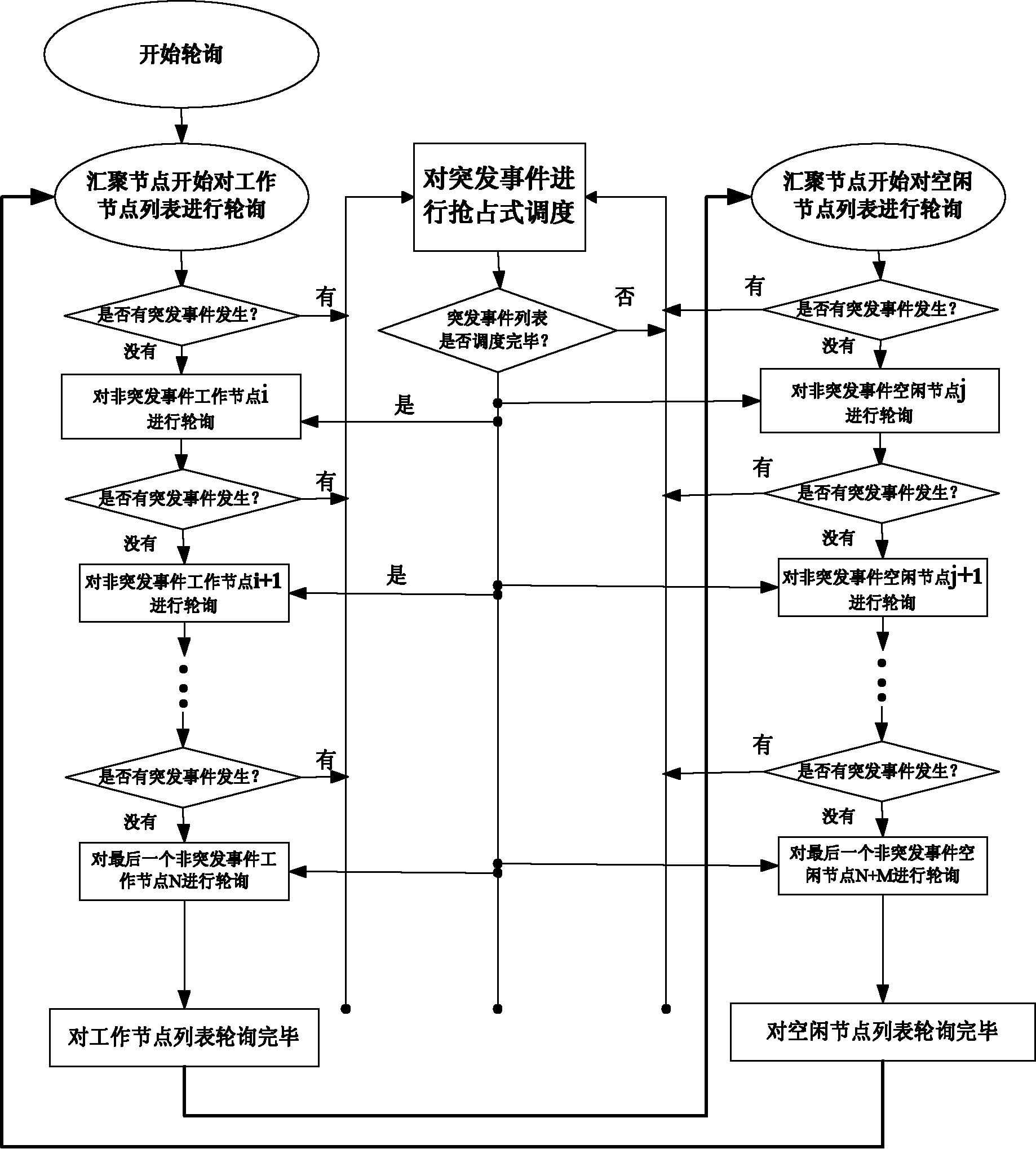

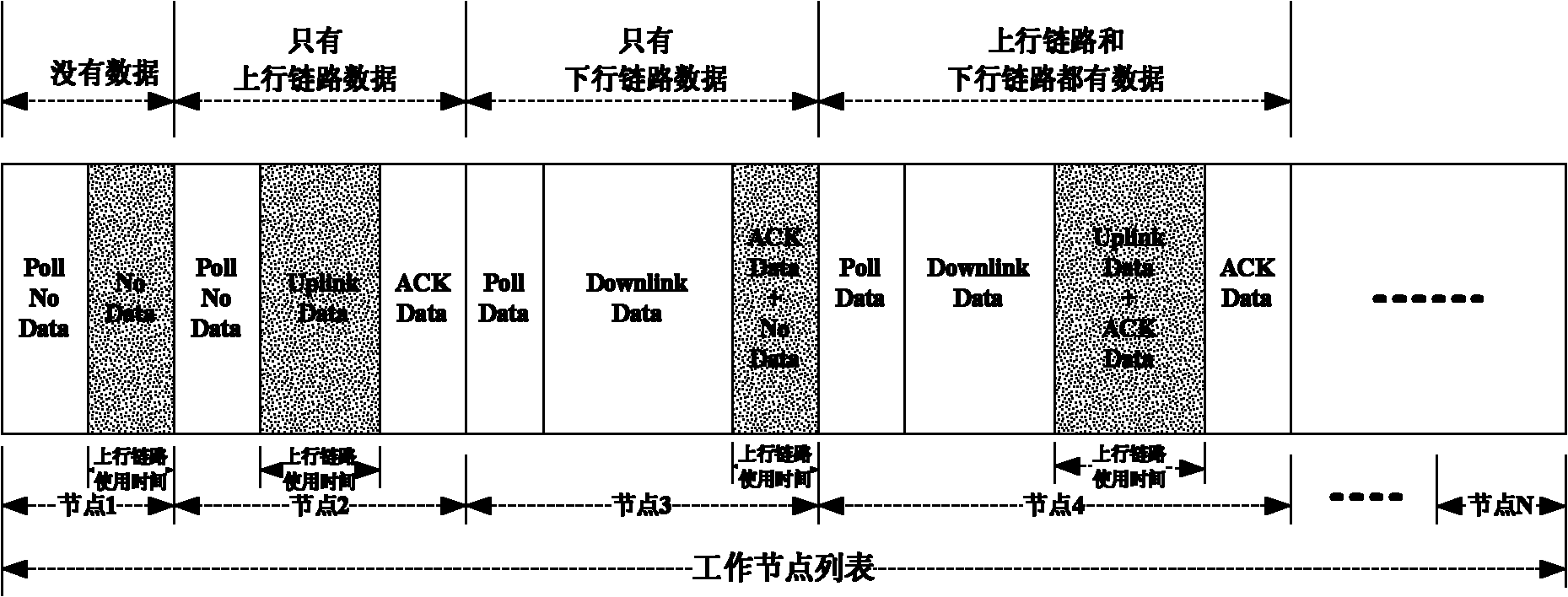

Dynamic polling medium access control method of emergency response supported sensor network

InactiveCN102006670ALimited timeImprove bandwidth utilizationError prevention/detection by using return channelWireless communicationLow delayWireless sensor network

The invention discloses a dynamic polling medium access control method of an emergency response supported sensor network, which mainly solves the problems of great access delay, low bandwidth utilization rate and high system expense of the traditional polling mode. The method comprises the following steps of: (1) polling a working node list by a sink node, firstly sending downlink data, then sending uplink data while sending an acknowledgment frame, dynamically distributing packet size and bandwidth for a working node, and controlling the time of the working node using an uplink; (2) polling an idle node list through a short frame sending / short frame response by the sink node; and (3) preemptively scheduling sudden events when the sink node polls the working node list and the idle node list. The invention has the advantages of small system expenses, low delay, high bandwidth utilization rate and emergency response to sudden events. The method is applicable to wireless sensor network channel access with high requirements on bandwidth and delay.

Owner:XIDIAN UNIV

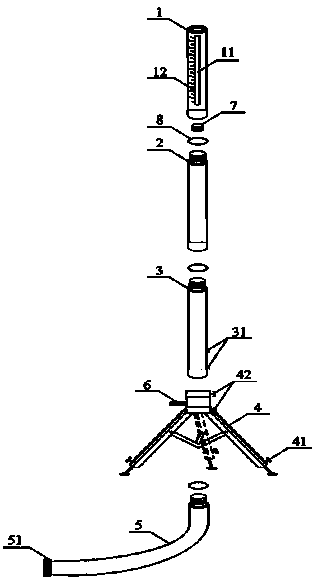

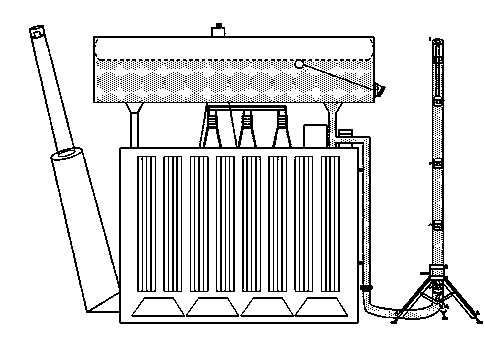

Live line measurement device for oil level of expansion tank of oil-immersed transformer

InactiveCN103822691AHigh measurement accuracyGood verticalityMachines/enginesLubrication indication devicesExpansion tankMeasurement device

The invention discloses a live line measurement device for the oil level of an expansion tank of an oil-immersed transformer. The live line measurement device comprises an upper-section measuring rod, a middle-section measuring rod, a lower-section measuring rod, a float, a tripod and a hose. The upper-section measuring rod, the middle-section measuring rod and the lower-section measuring rod are hollow insulation rods and are detachably connected to form a hollow straight rod, the float is arranged in the hollow straight rod, the tail end of the bottom of the lower-section measuring rod is fixed to the top of the tripod and connected with one end of the hose, the other end of the hose is connected with an oil injection and drain valve of the oil-immersed transformer through a connection port, and the side face of the upper-section measuring rod is provided with scale marks and a corresponding observation window. According to the principle of communicating vessels, the live line measurement device can be used for measuring the actual height of the oil level in the expansion tank of the transformer accurately, and is simple to operate, convenient to carry and good in safety.

Owner:国网安徽省电力公司检修公司 +1

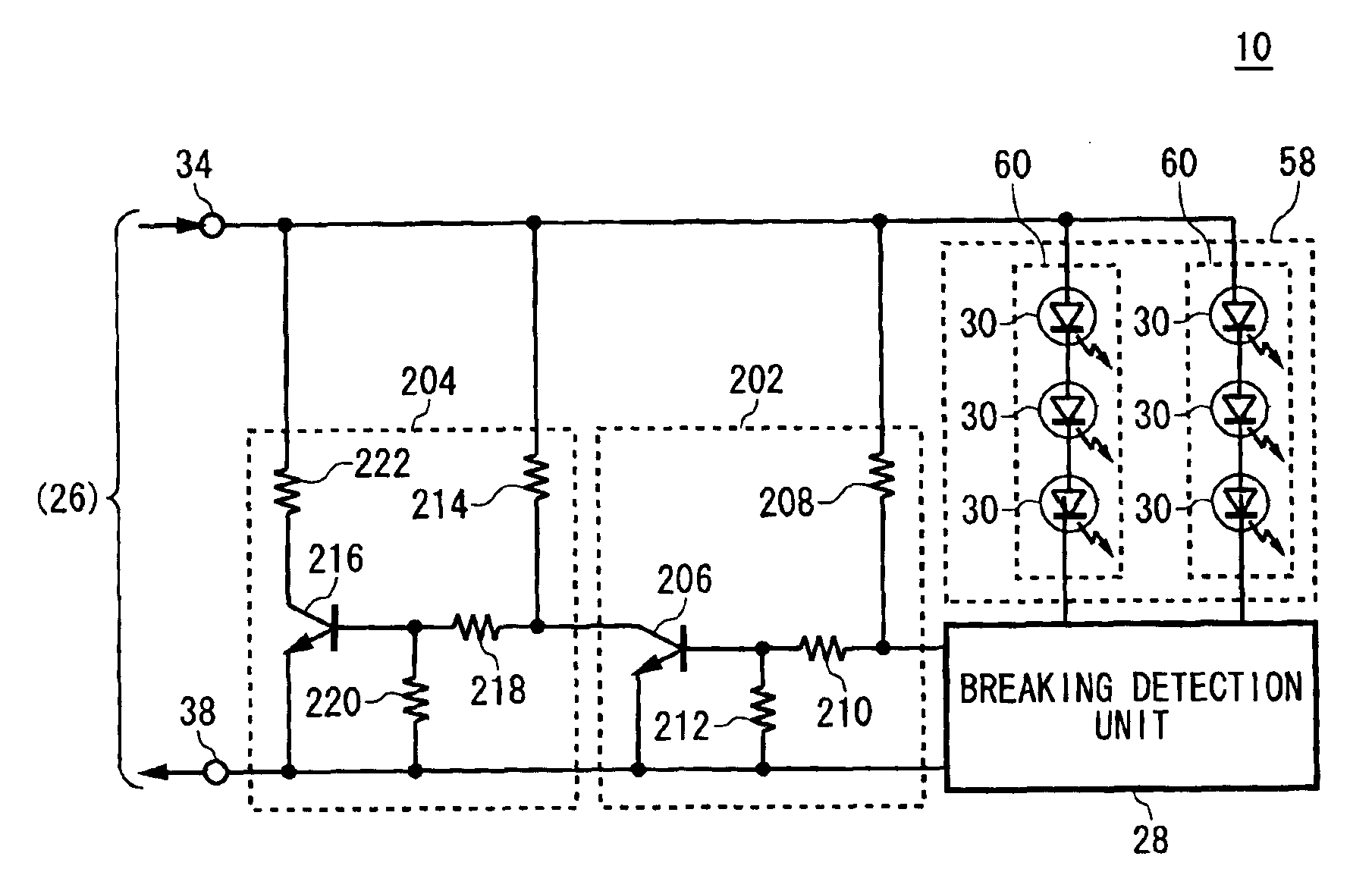

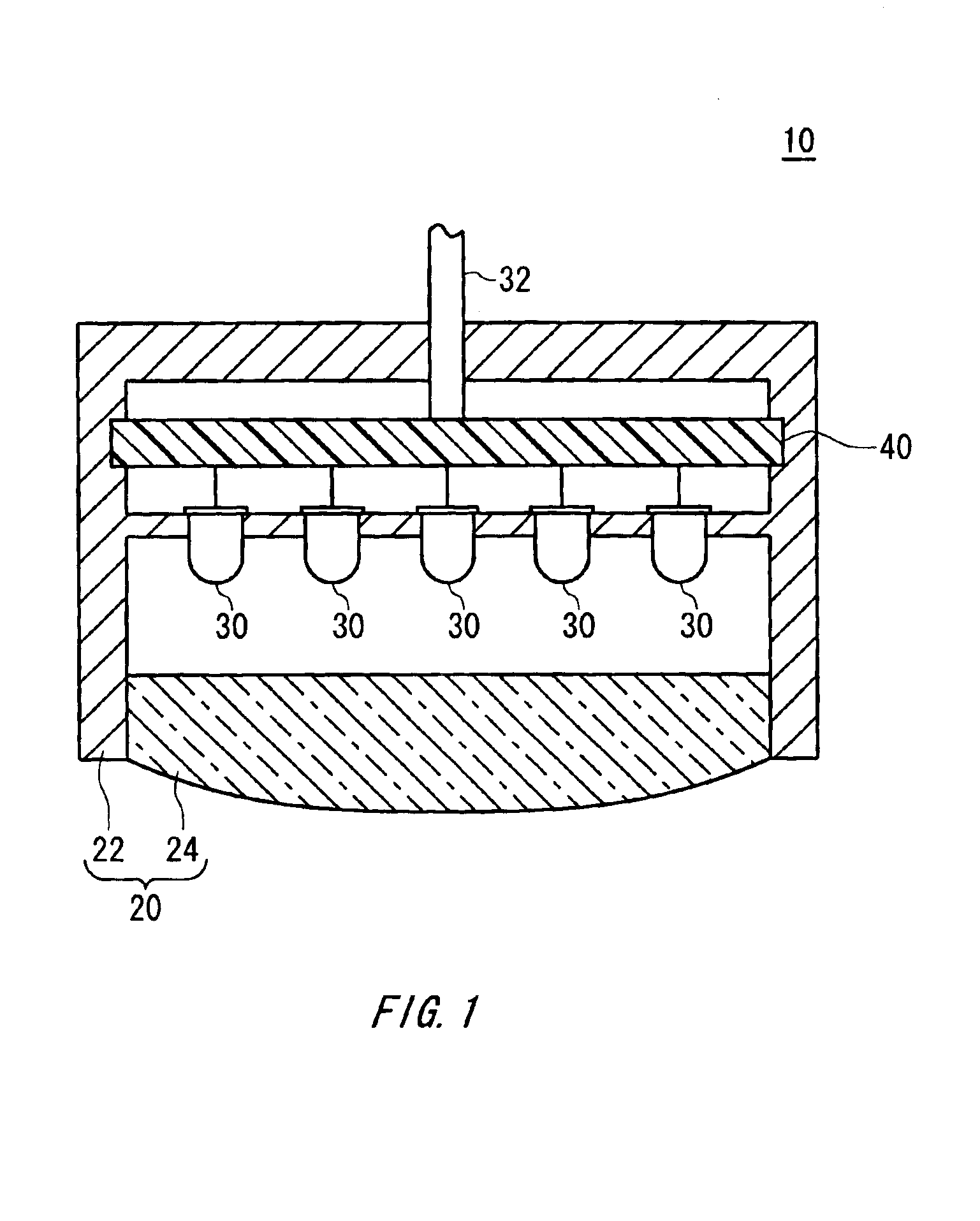

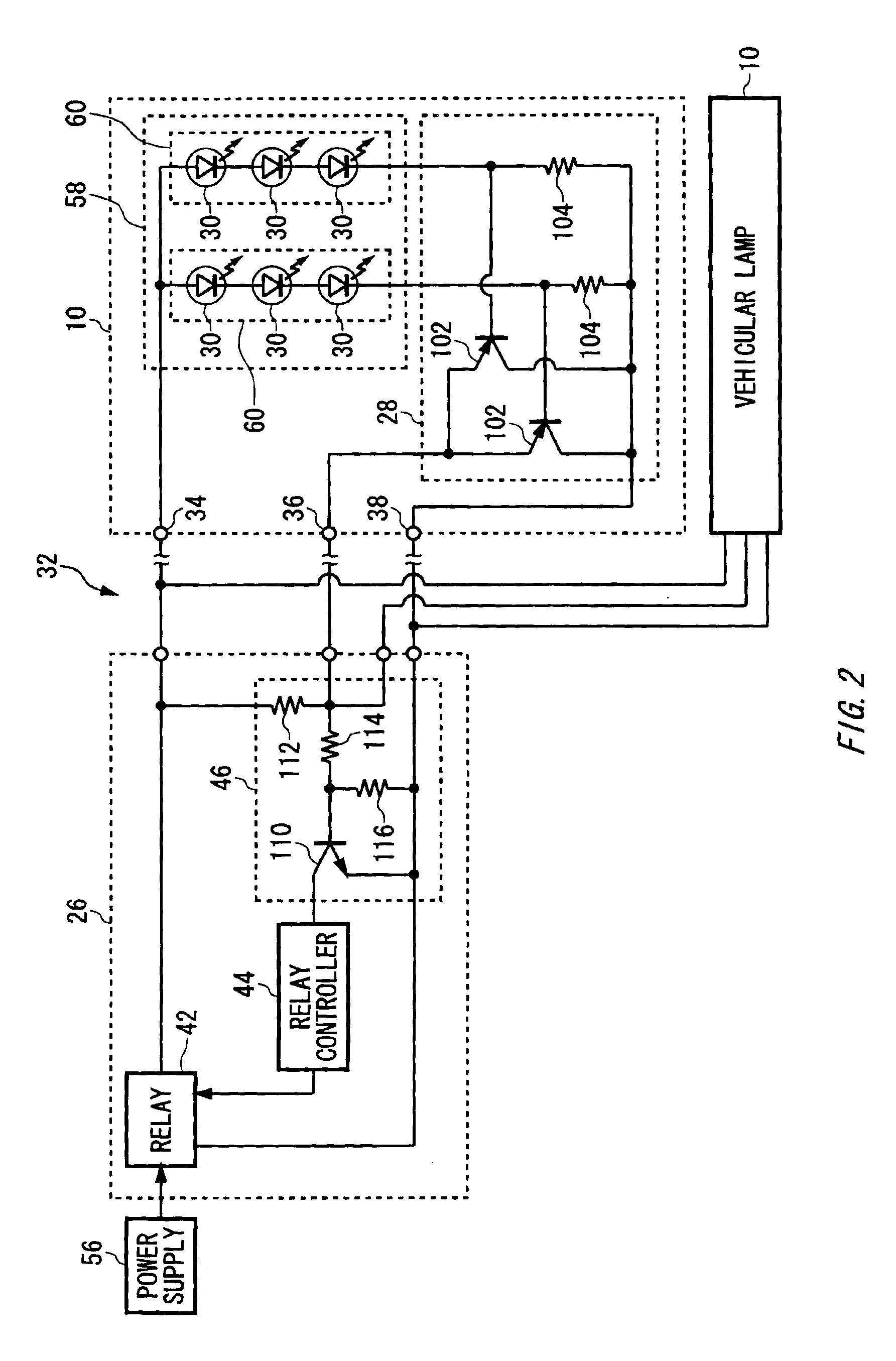

Vehicular lamp

InactiveUS6917166B2Small valueLimited timeElectroluminescent light sourcesSemiconductor lamp usageEngineeringLight source

A vehicular lamp used in a vehicle, includes: a light source including a light-emitting diode for emitting light in accordance with power received from a power supply provided in the outside of the vehicular lamp; a lamp body for accommodating the light source therein to protect the light source from water; and a breaking detection unit for detecting breaking of the light source and notifying the outside of the lamp body of the detection result.

Owner:KOITO MFG CO LTD

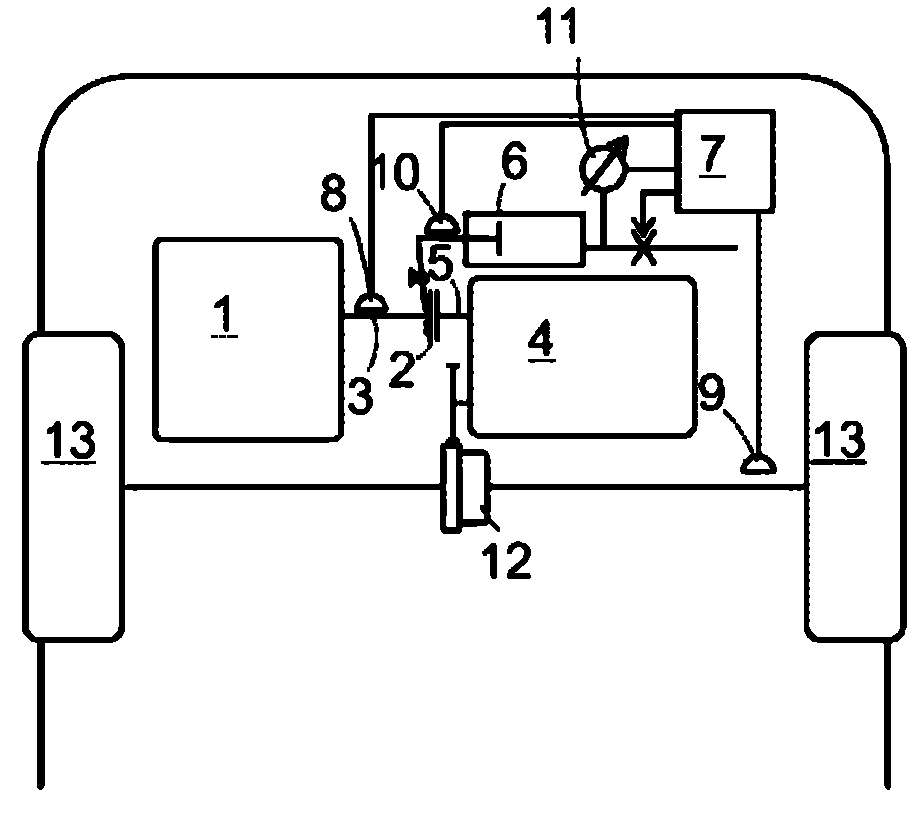

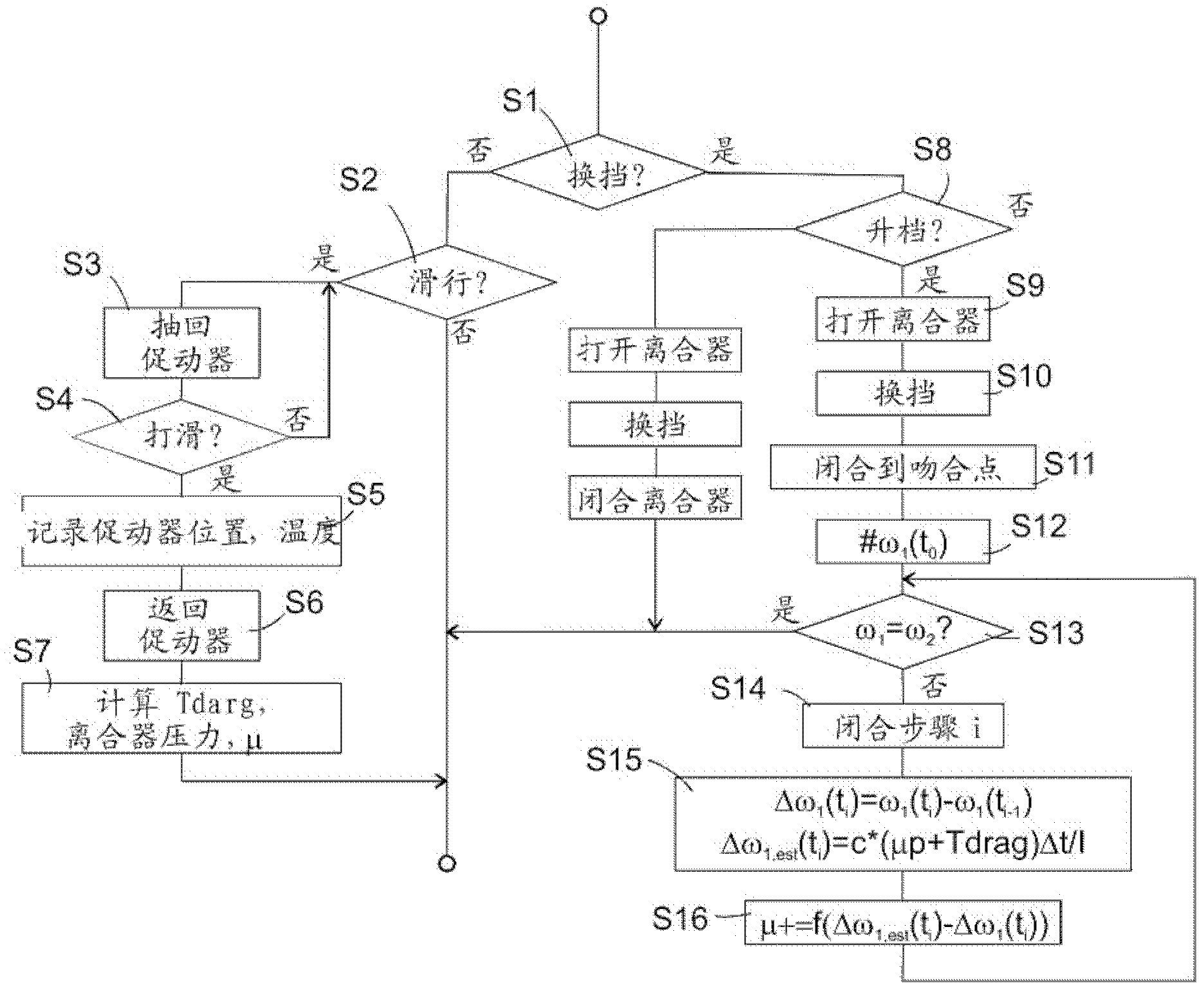

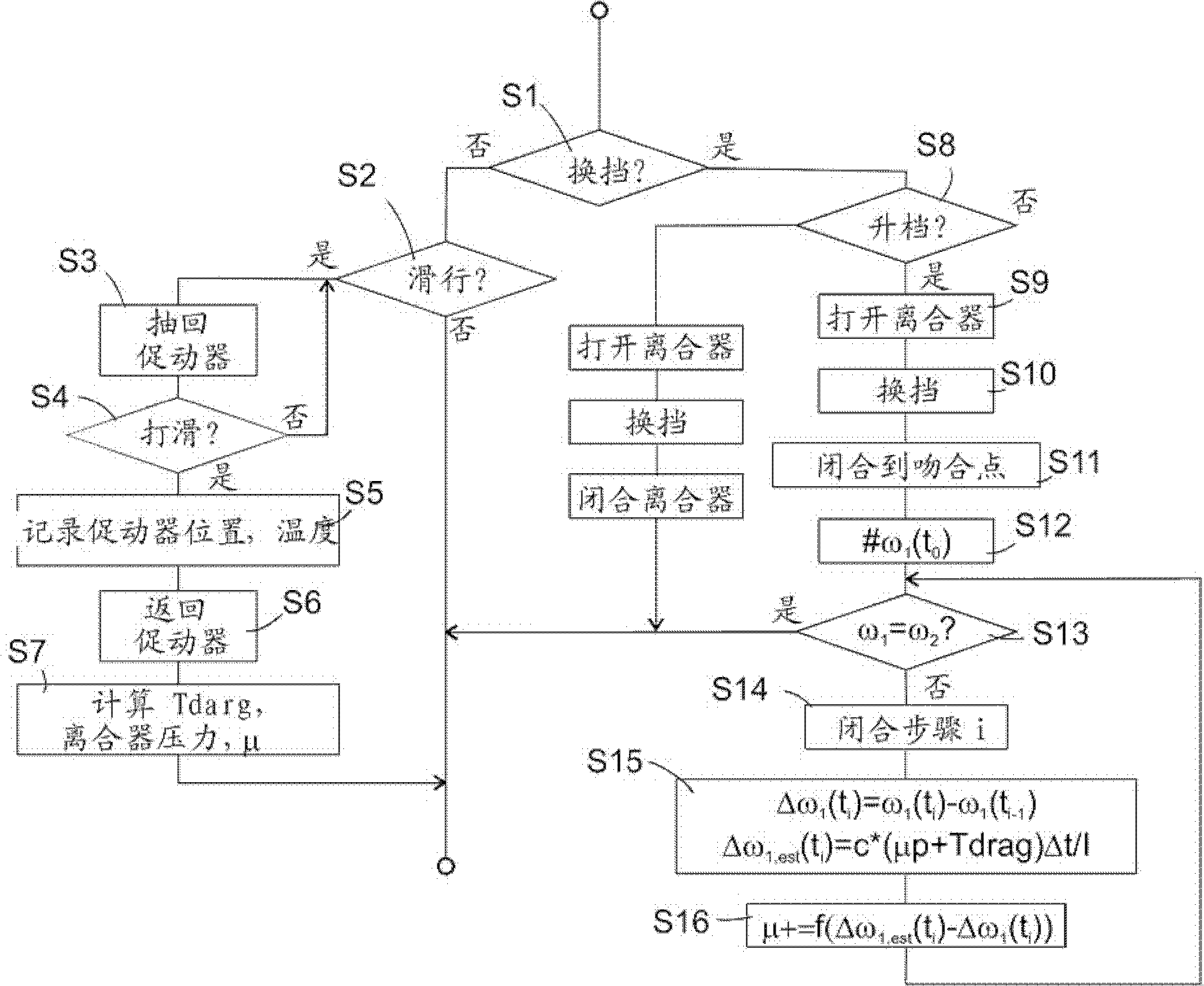

Method and apparatus for estimating clutch friction coefficient

InactiveCN102422043ARemove imprecisionLimited timeClutchesGearing controlDrag torqueAngular acceleration

A method for estimating a transmissibility of a clutch in a vehicle powertrain, comprises the steps of : a) cutting off fuel supply of an engine driving a first side of the clutch, b) setting a clutch pressure between first and second sides of the clutch to a positive value at which there is a non-zero difference between angular accelerations at the first and second sides of the clutch (S3, S4), c) deriving said estimated transmissibility from a deviation between said angular acceleration difference and an angular acceleration caused by a drag torque of the engine (S7).

Owner:GM GLOBAL TECH OPERATIONS LLC

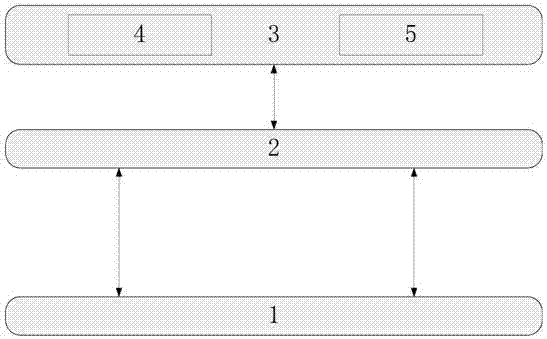

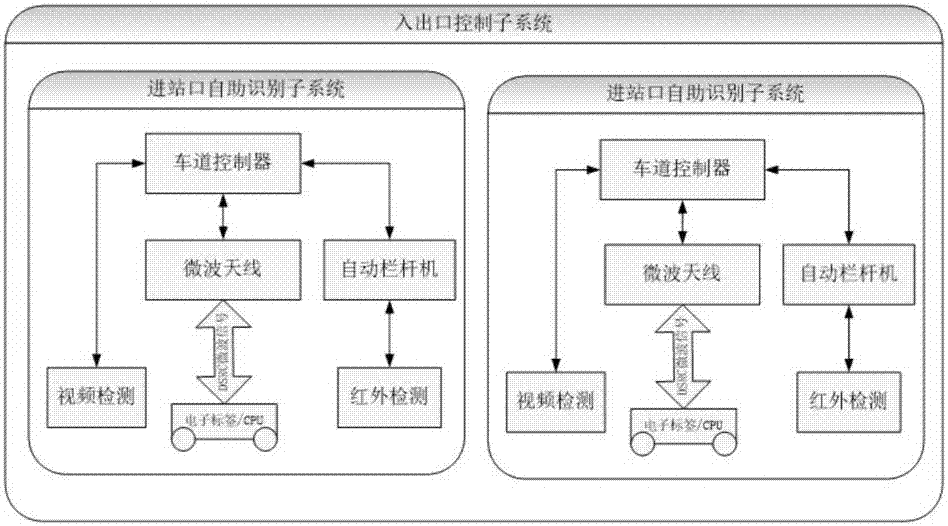

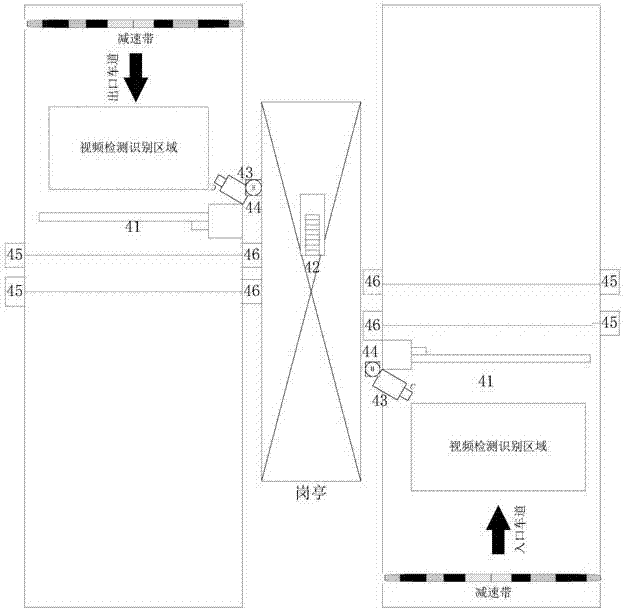

Passenger station video infrared detection intelligent access control management system

PendingCN107492177ANovel and reasonable designSimple structureIndividual entry/exit registersManagement systemNetwork communication

A video infrared detection intelligent access control management system comprises an entrance / exit control subsystem, a network communication subsystem and a center management subsystem, performs construction by selecting video detection, identification and infrared auxiliary detection methods instead of a ground sense detection coil technology needing large construction quantity, and is novel and reasonable in design, simple in structure, convenient to mount and convenient in later maintenance, reduces cost and reduces construction quantity.

Owner:北京易商创客科技有限公司

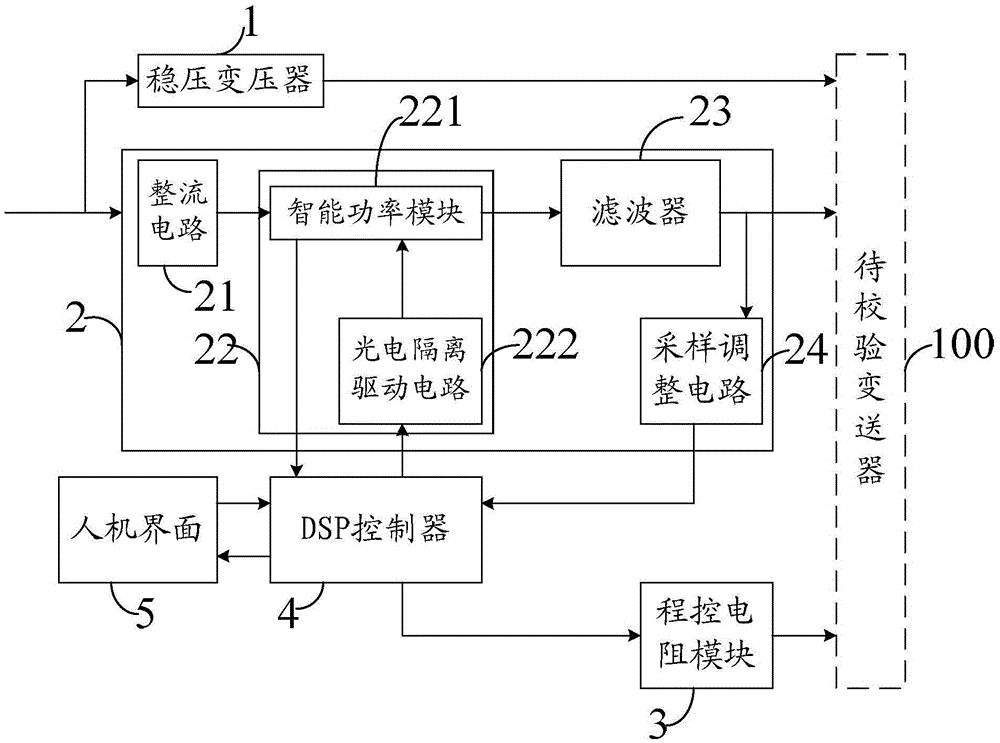

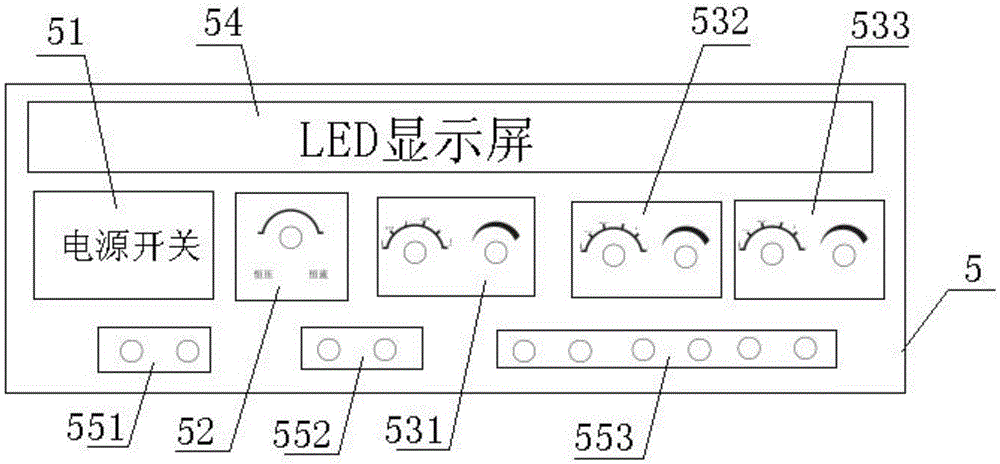

Portable transmitter calibrator

The invention discloses a portable transmitter calibrator, comprising a voltage stabilizing transformer, an alternating-current constant voltage and constant current module, a program controlled resistor module, a DSP (Digital Signal Processor) controller and a human-computer interface, wherein the alternating-current constant voltage and constant current module comprises a rectifying circuit, an inverter, a filter and a sampling adjustment circuit; the inverter comprises an intelligent power module and a photoelectric isolating drive circuit; the voltage stabilizing transformer is connected with a transmitter to be calibrated; the output end of the sampling adjustment circuit is connected with the DSP controller; the program controlled resistor module is separately connected with the DSP controller and the transmitter to be calibrated; and the human-computer interface is connected with the DSP controller. The portable transmitter calibrator can realize convenient calibration for multiple transmitters, has the characteristics of multiple functions, small size, light mass, portability and the like, and can significantly improve the convenience of transmitter calibration and save money.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

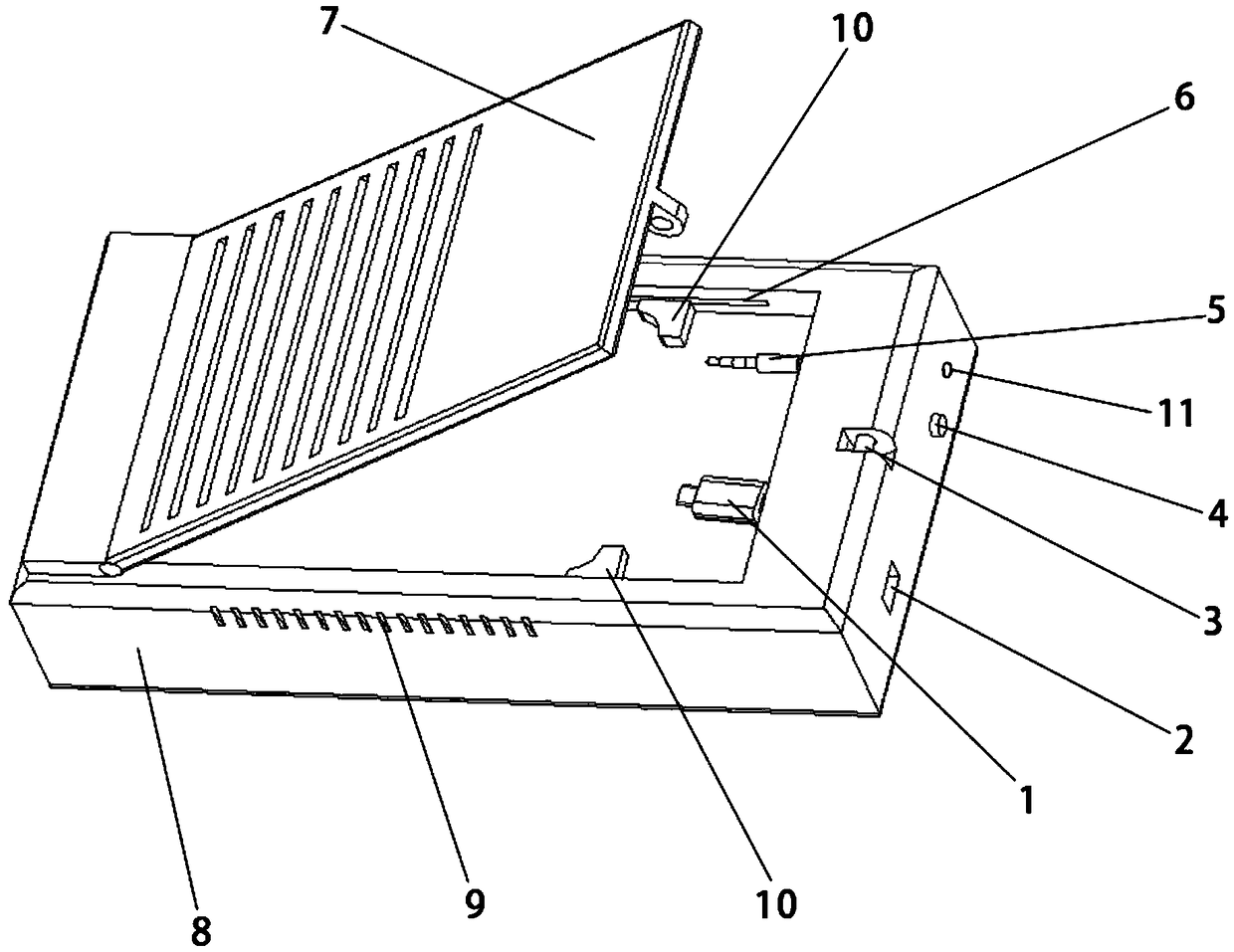

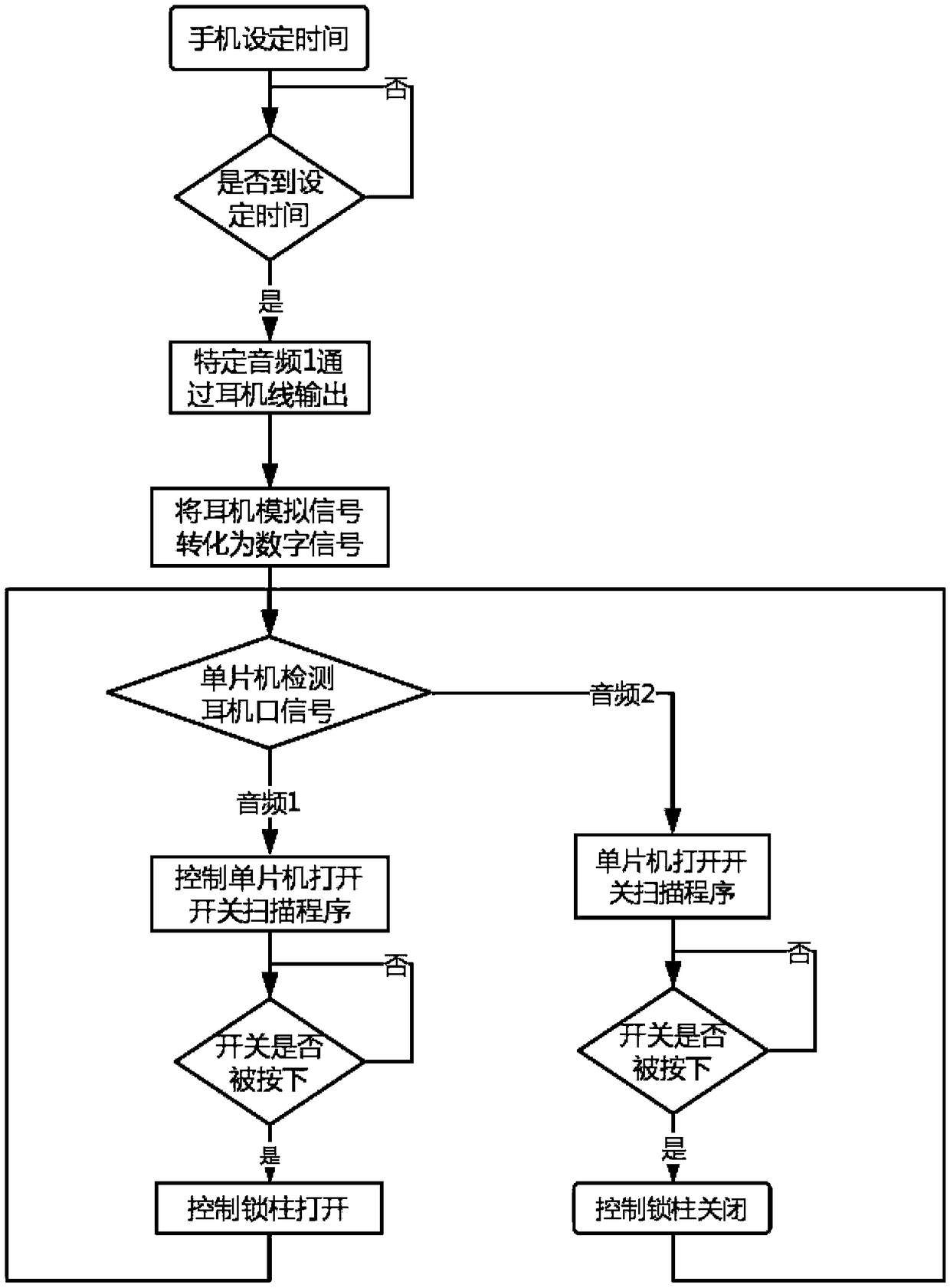

Device and method for restriction of usage time of mobile phone

PendingCN109194809ATime suppressionEasy to useBatteries circuit arrangementsElectric powerData entryElectromagnetic lock

The present invention provides a device and a method for restriction of usage time of a mobile phone. The device comprises a box body, a cover plate and an electromagnetic lock, the box body is provided with a control device and an audio signal receiving device, the audio signal receiving device is configured to receive audio output signals of the mobile phone, the data input end of the control device is connected with the audio signal receiving device, the data output end of the control device is connected with the electromagnetic lock, and when the audio signal receiving device receives predetermined audio signals output by the audio output device of the mobile phone, the control device opens the electromagnetic lock. The device and the method for restriction of usage time of the mobilephone can better efficiently restrict the time of students playing the mobile phone so as to overcome the defects that the usage time of the mobile phone cannot be restricted due to restriction limitation by employing methods such as restarting and closing of the APP.

Owner:汪涛

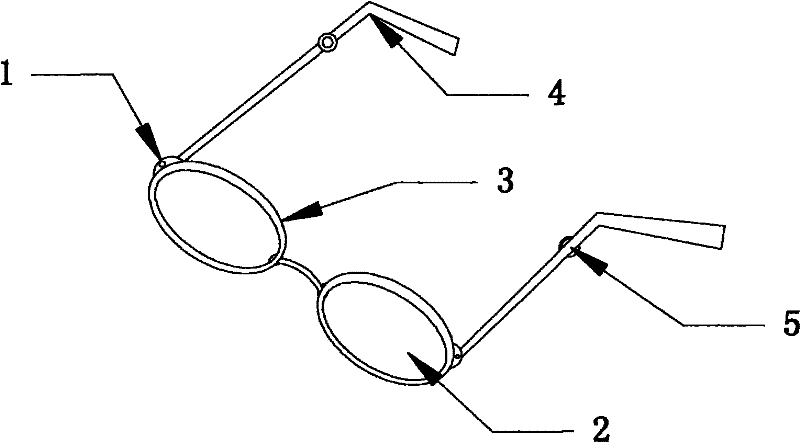

Glasses device capable of reminding user of eyestrain

The invention discloses a glasses device capable of reminding a user of eyestrain. A micro infrared sensor for reminding the user of keeping a distance away from a book and a computer screen and a device for testing eyestrain, limiting eye use time and reminding the user of closing the eyes for rest are arranged in a glasses framework.

Owner:陈雪如

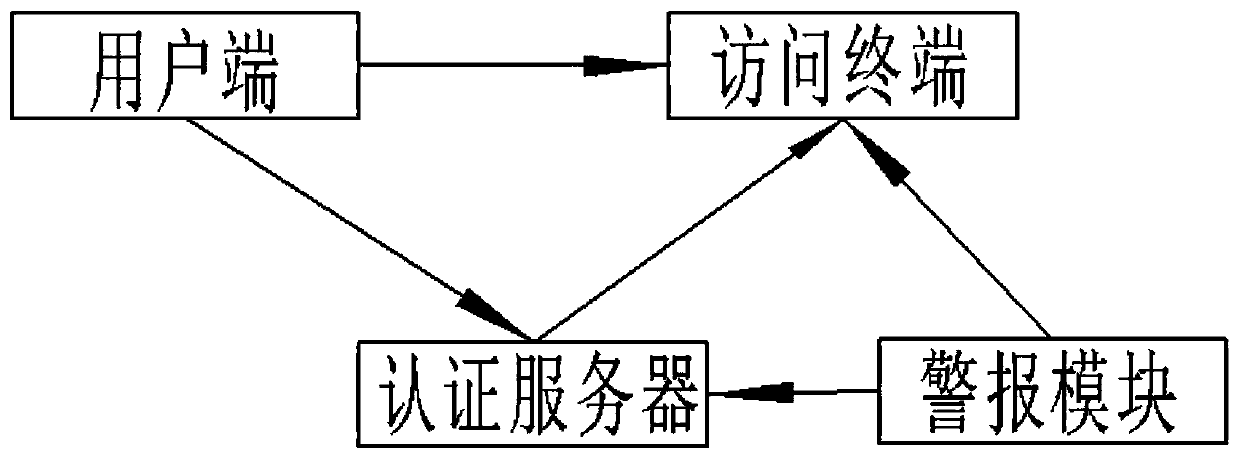

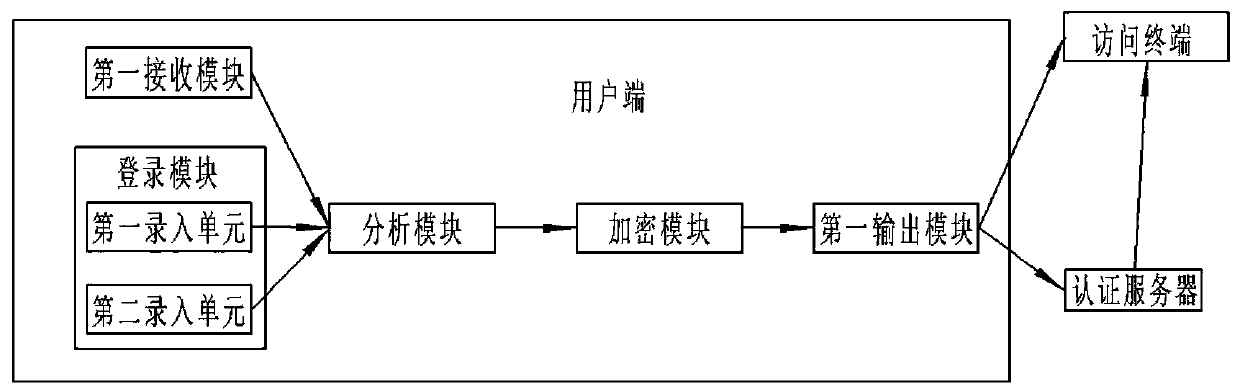

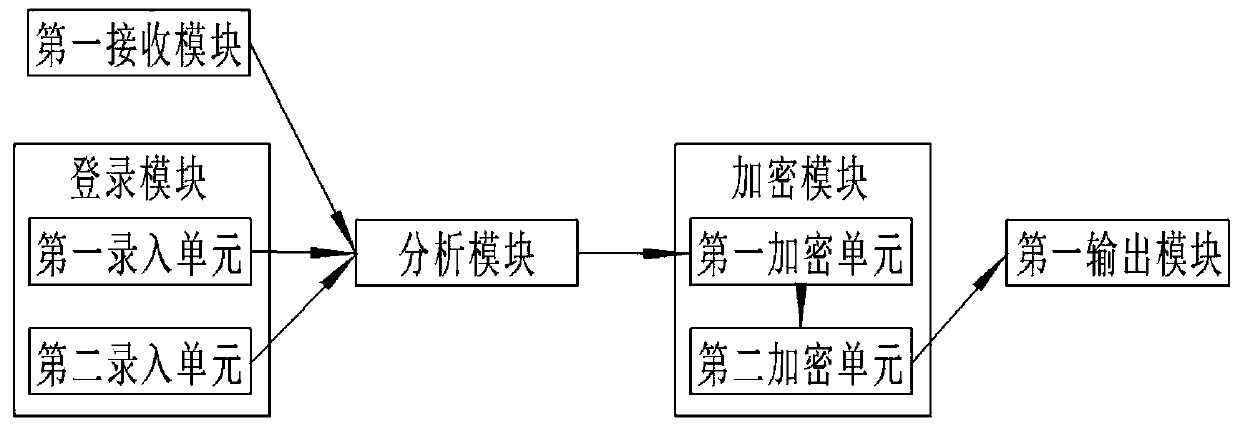

Privacy protection system and method based on big data analysis and trusted computing

PendingCN110378135AReduce the risk of privacy breachesReasonable module designDigital data protectionElectricityTrusted Computing

The invention discloses a privacy protection system and method based on big data analysis and trusted computing. The privacy protection system comprises a user side, an authentication server and an access terminal, the user side is in wireless connection with the authentication server and the access terminal, the authentication server is in wireless connection with the access terminal, the privacyprotection system further comprises an alarm module, and the alarm module is in wireless connection with the authentication server and the access terminal. The user side comprises a login module, a first receiving module, an analysis module, an encryption module and a first output module, the login module and the first receiving module are electrically connected with the analysis module, and theanalysis module, the encryption module and the first output module are electrically connected in sequence; the module is reasonable in design, the privacy protection strength is improved by endowing the pseudonym operation through the authentication server, meanwhile, during network access, the situation that a user reduces the privacy leakage risk can be effectively avoided, and high practicability is achieved.

Owner:武汉东湖大数据交易中心股份有限公司

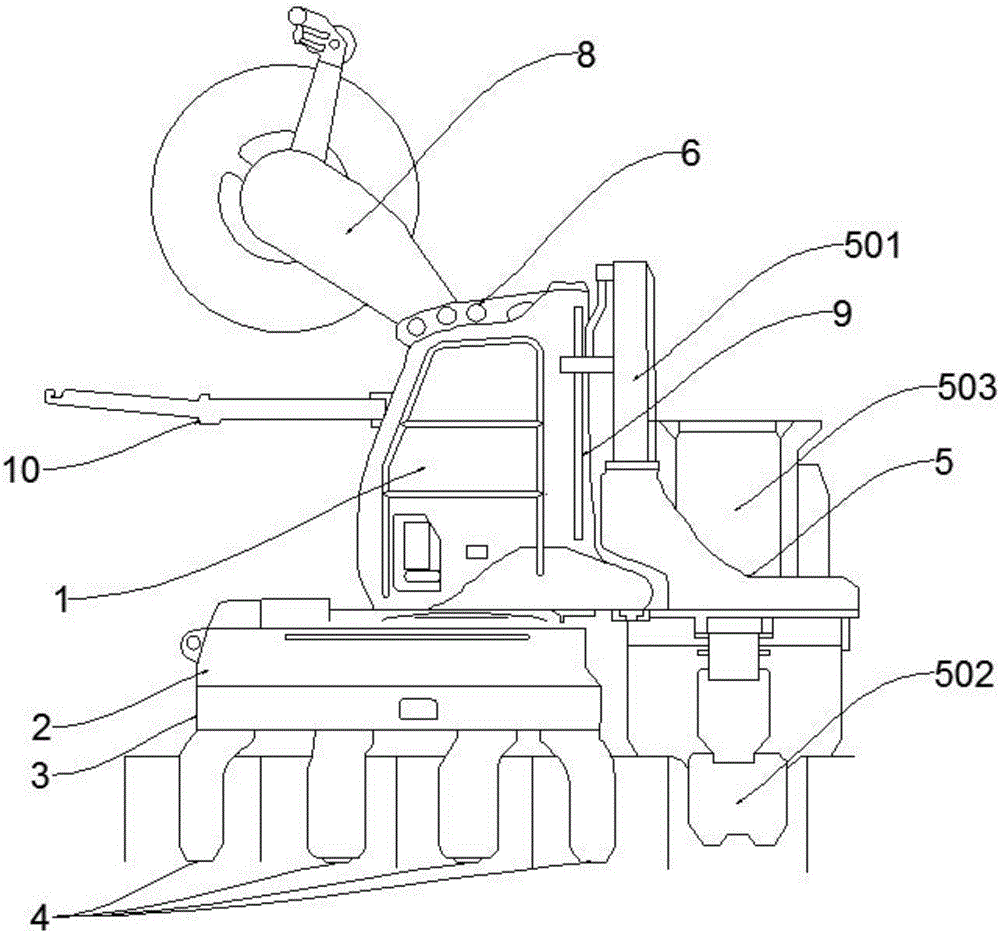

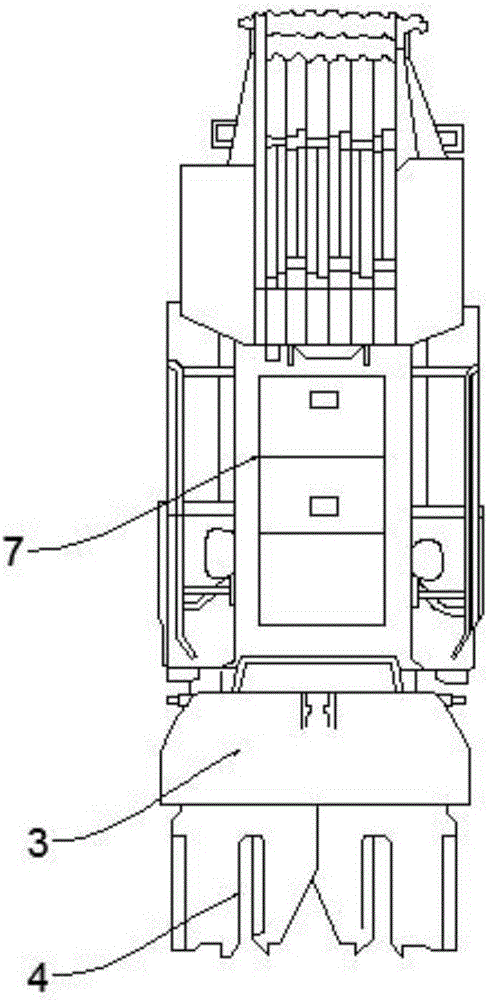

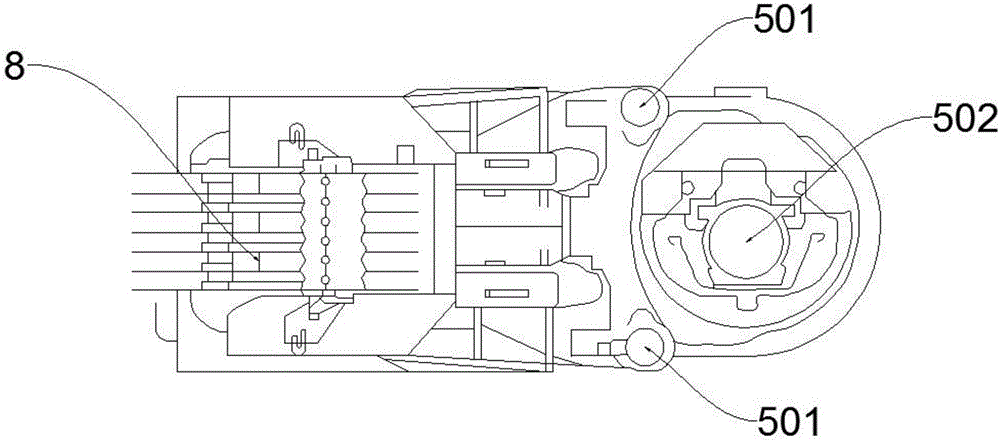

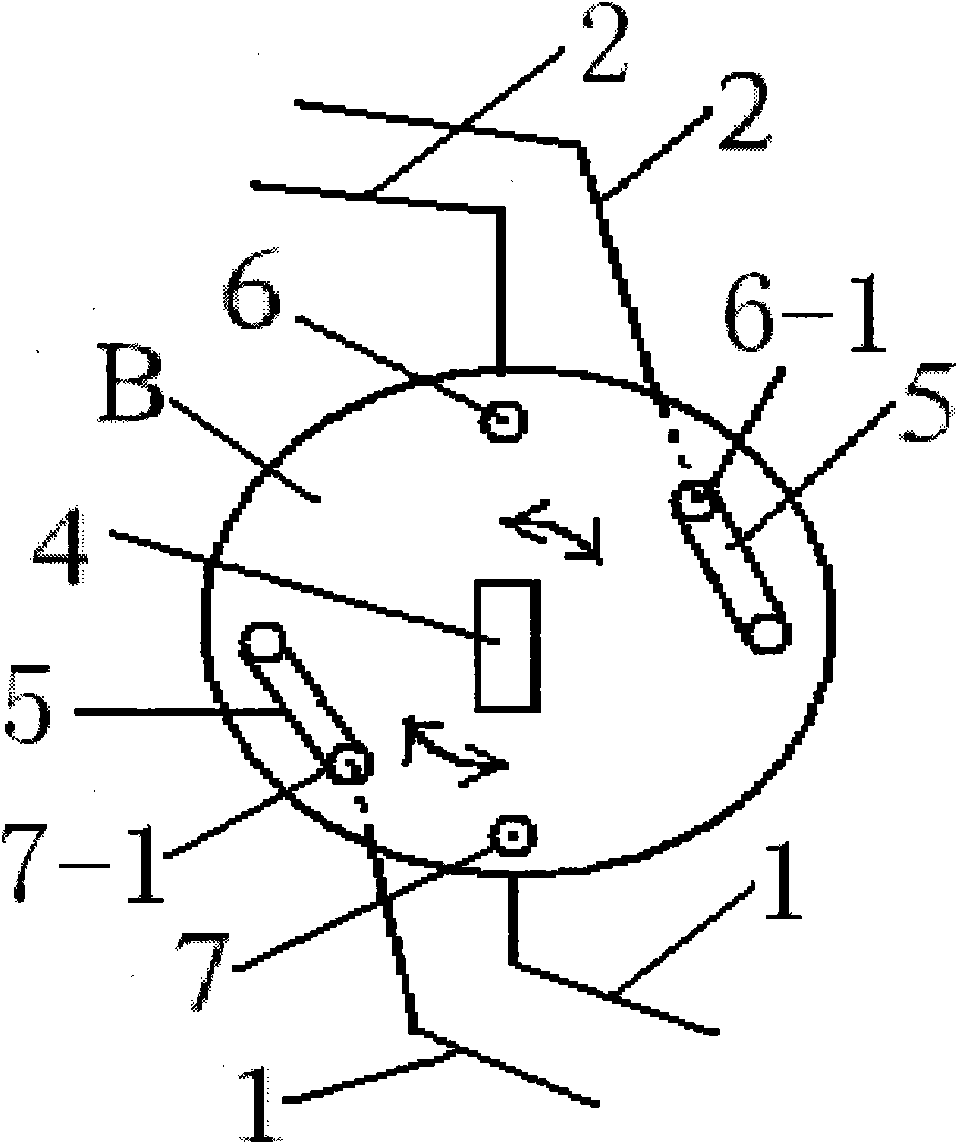

Pile pressing machine

ActiveCN106013150AAvoid safety accidentsEstricted environmentBulkheads/pilesEngineeringMachine press

The invention relates to a pile pressing machine which comprises a press machine body and a chuck (5). The chuck (5) is connected to the press machine body through a pin shaft. The press machine body comprises an upper machine body (1), a sliding seat (2), a base (3) and fixing clamps (4). The fixing clamps (4) are connected with the base (3). The base (3) is connected with the sliding seat (2). The upper machine body (1) is arranged on the sliding seat (2) and provided with installation holes (6) and a controller (7). The installation holes (6) are used for being connected with other components. The chuck (5) comprises a protecting mechanism (503), a hydraulic mechanism (501) and a clamping mechanism (502). By the adoption of the pile pressing machine, a pile planting manner is changed, hydraulic pressure is adopted for planting a pile, and the pile pressing machine has the beneficial effects of being low in noise, small in vibration, small in influence on a soil layer and the like.

Owner:桩研科技(大连)有限公司

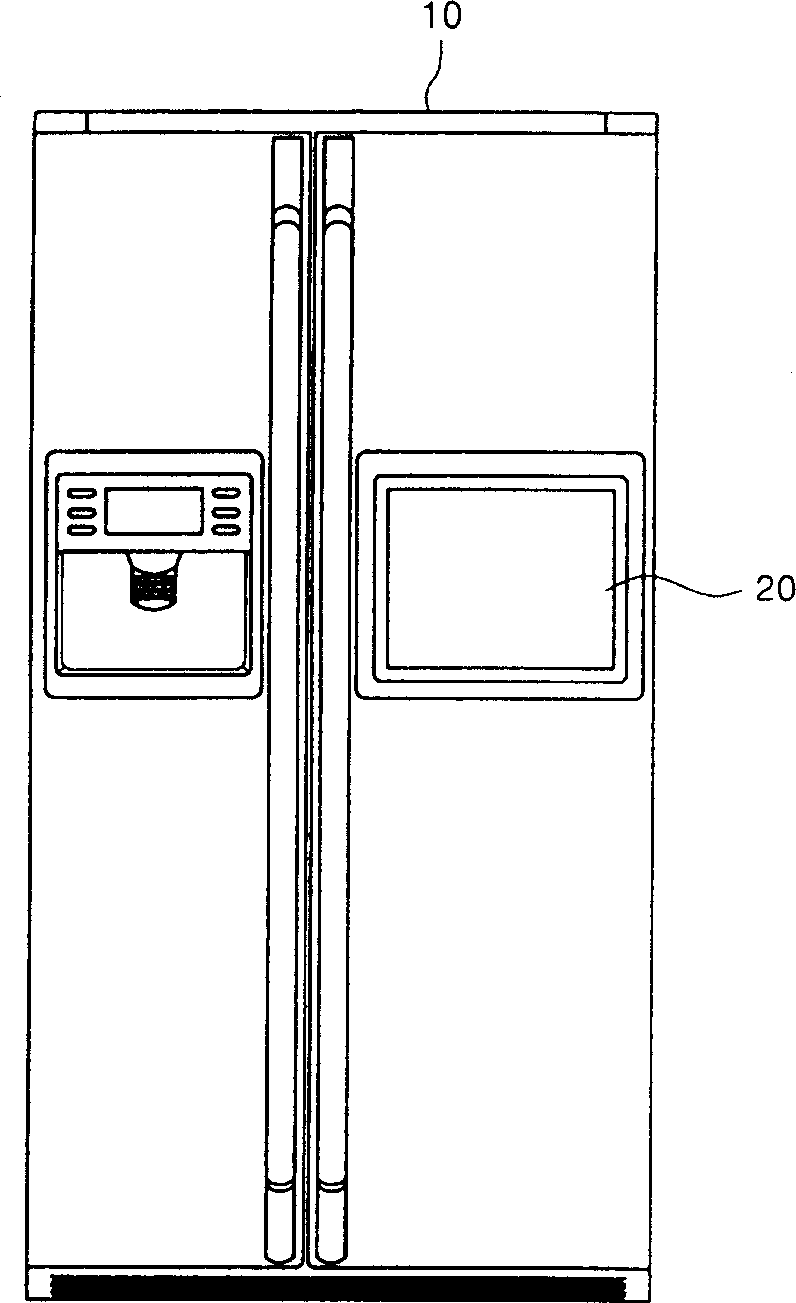

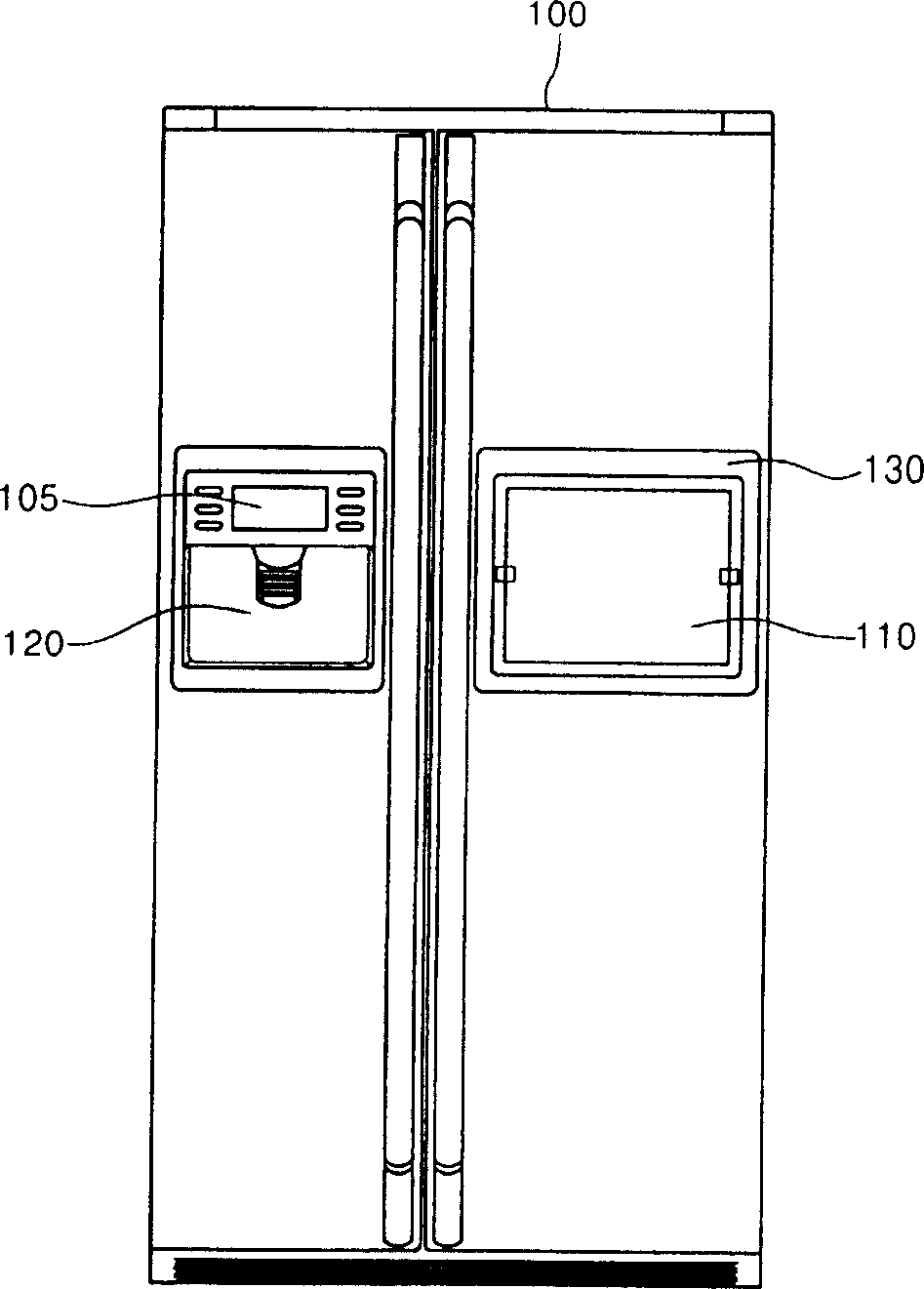

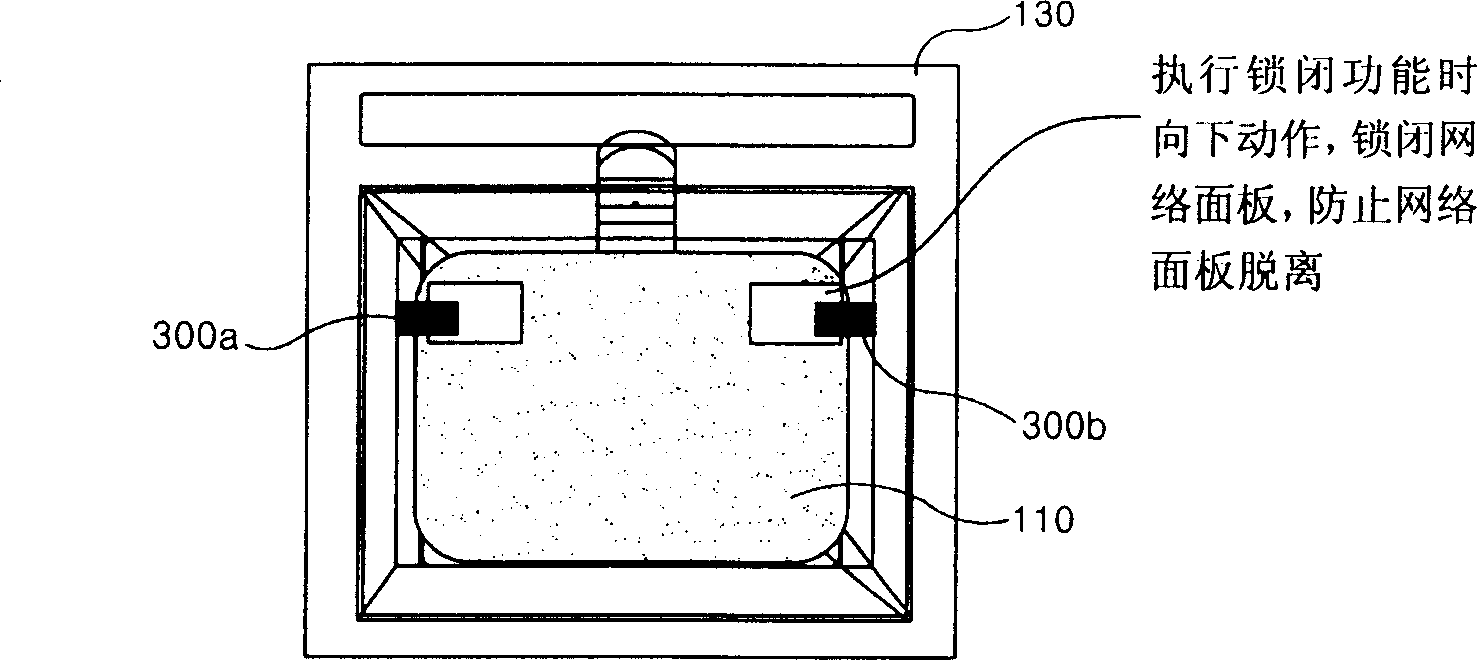

Network panel locking control device for network refrigerator

InactiveCN1766504ALimited timeLimited movement spaceDomestic cooling apparatusLighting and heating apparatusEngineeringElectrical and Electronics engineering

The invention discloses a network panel locking control device of network refrigerator, which is characterized by the following: assembling or dismounting the network panel on or from the network refrigerator through the locking or unlocking operation; setting the locking device on the host of network refrigerator; inputting the prior setting code through the network panel when canceling locking state; sending the unlocking signal due to the consistent code. The invention prevents the children or unfamiliar from demounting the network panel, which reduces the damage or burglar.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

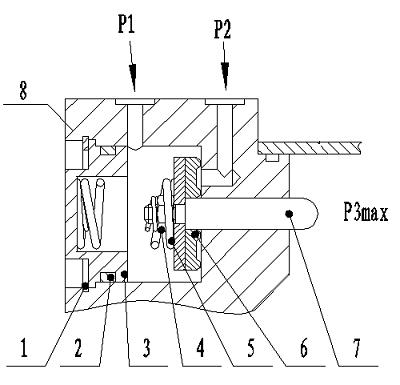

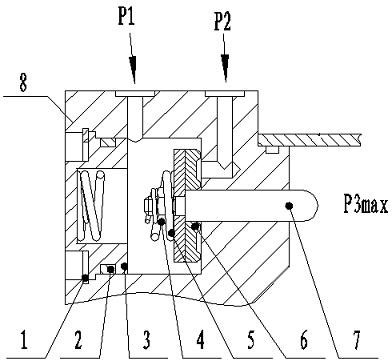

Electrolytic aluminium crust breaking cylinder feedback valve

The invention discloses an electrolytic aluminium crust breaking cylinder feedback valve, which comprises a back-up ring (1), an O-shaped loop (2), a gland (3), a spring (5), a special-purpose seal (6) and a contact rod (7), wherein the O-shape loop (2) is installed inside the groove of the gland (3), which is fixed on a front cover (8) through the back-up ring (1); the spring (5) is installed inside a counter bore of the gland (3); the special-purpose seal (6) is connected with the contact rod (7) through a nut (4). After crust breaking by the cylinder is completed, the electrolytic aluminium crust breaking cylinder feedback valve will immediately sound a feedback signal so as to control the cylinder to rapidly withdraw, limit the residence time of a hammerhead in an aluminium liquid, detect the state of the hammerhead in the aluminium liquid and raise the purity of the aluminium liquid.

Owner:大连维乐液压制造有限公司

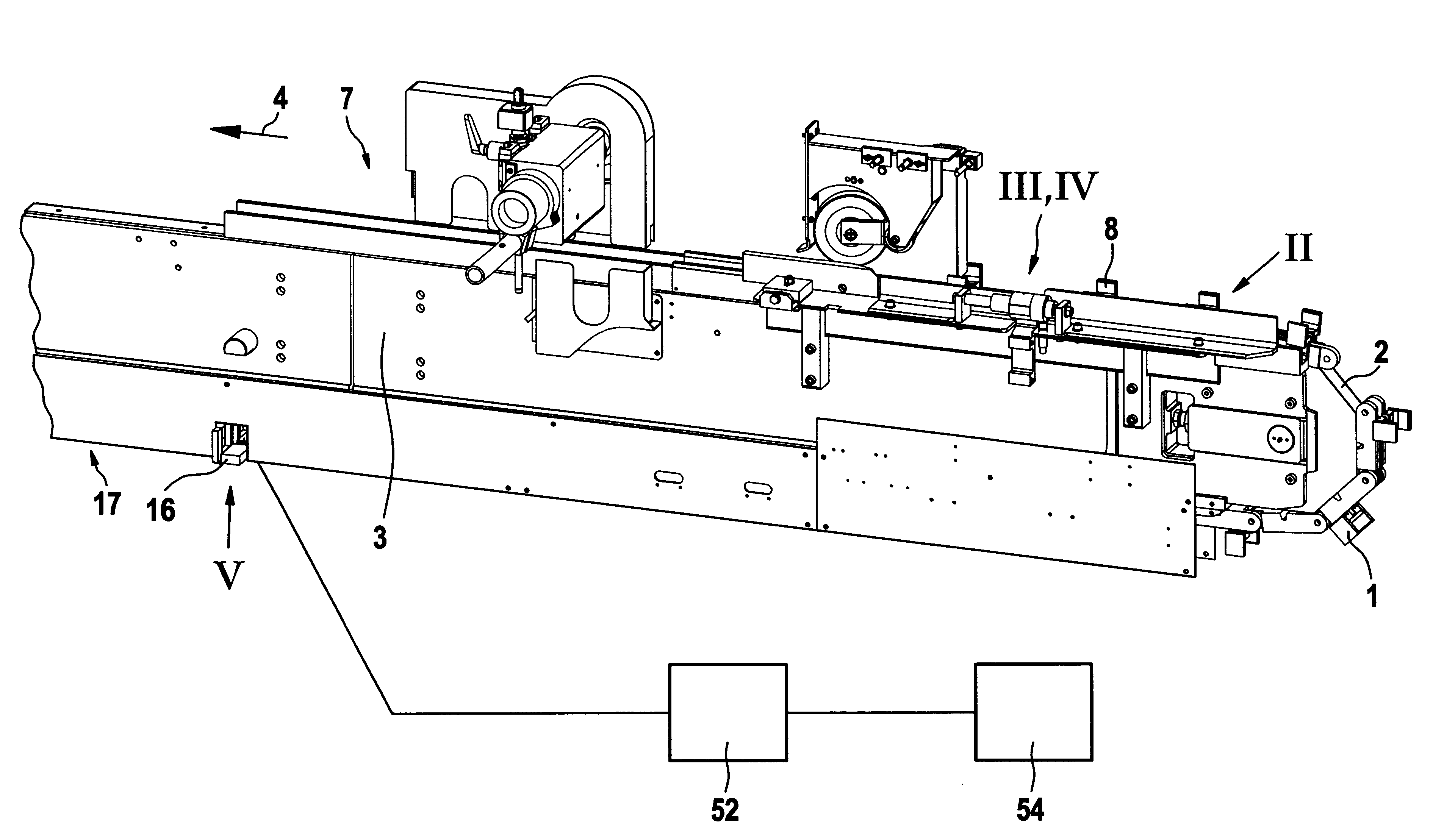

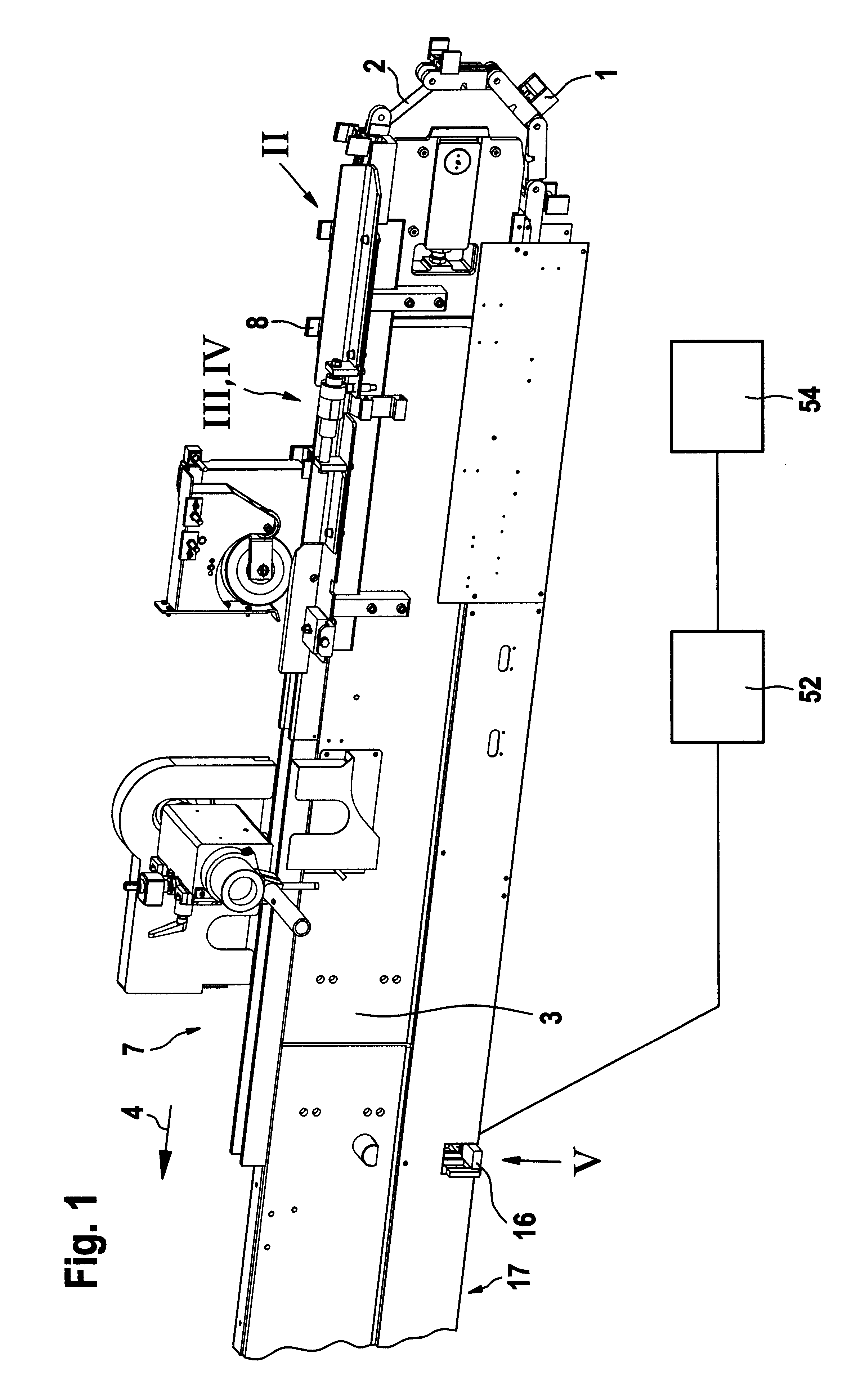

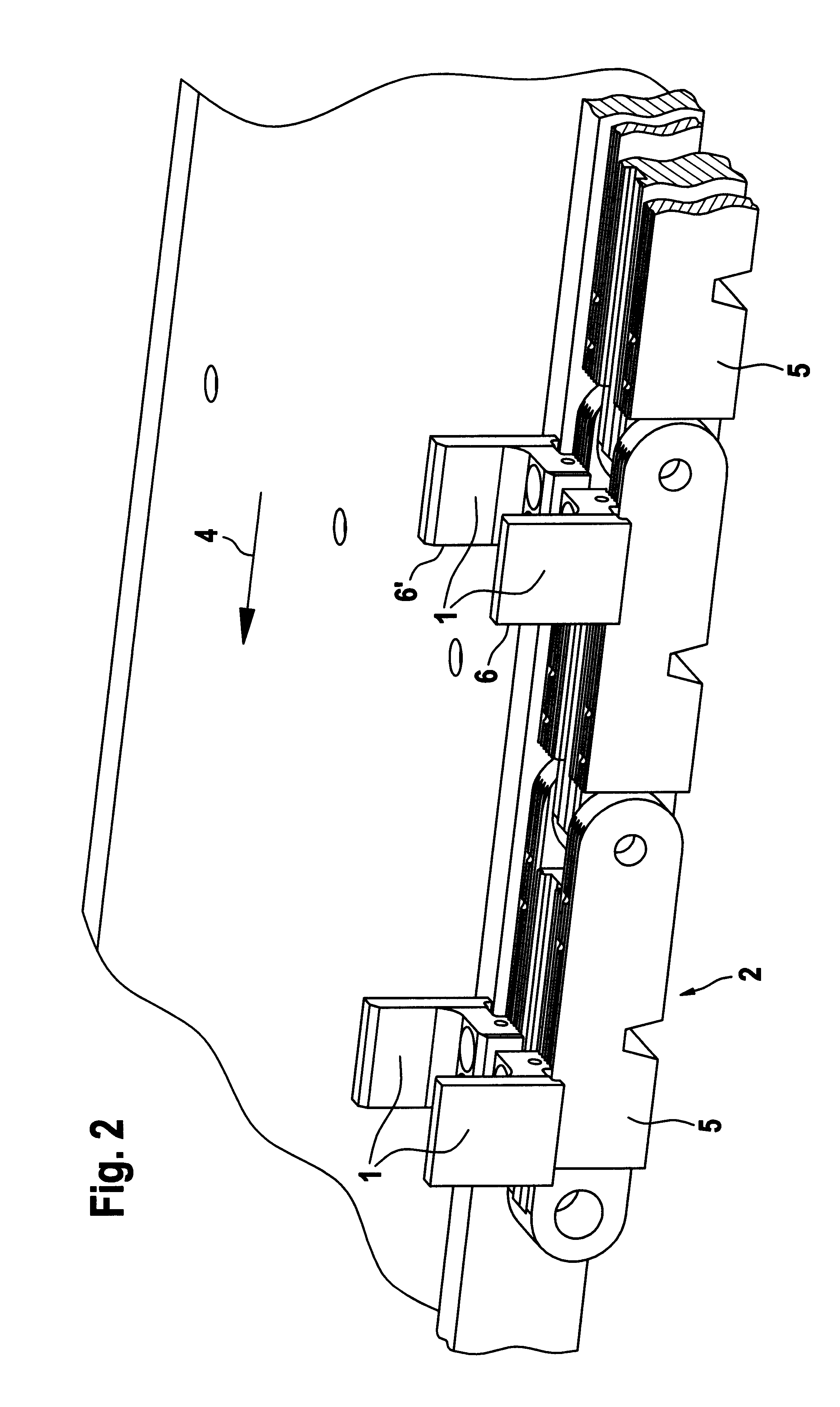

Aligning and feeding device for panel-shaped workpieces

InactiveUS6550601B2High degree of measurement accuracyLimited timeTongue/grooves making apparatusDovetailed workEngineeringMeasurement plane

In order to monitor the adjustment state of the entrainers (1), which are arranged in each case in pairs transverse to the feed direction (4), of a feed chain (2), it is proposed to arrange an adjusting station along the guide of the feed chain (2) and to arrange a measuring station at a spaced interval therefrom. The adjusting station serves to adjust manually the entrainers (1) in a common adjusting plane extending perpendicular to the feed direction (4), whereas the measuring station is arranged to detect the adjustment position of the two entrainers (1) in a measuring plane likewise perpendicular to the feed direction (4) and, in accordance with a tolerance field which can be defined by the user, to generate an error signal which at the same time renders it possible to identify maladjusted entrainers (1).

Owner:GRECON DIMTER HOLZOPTIMIERUNG SUD GMBH

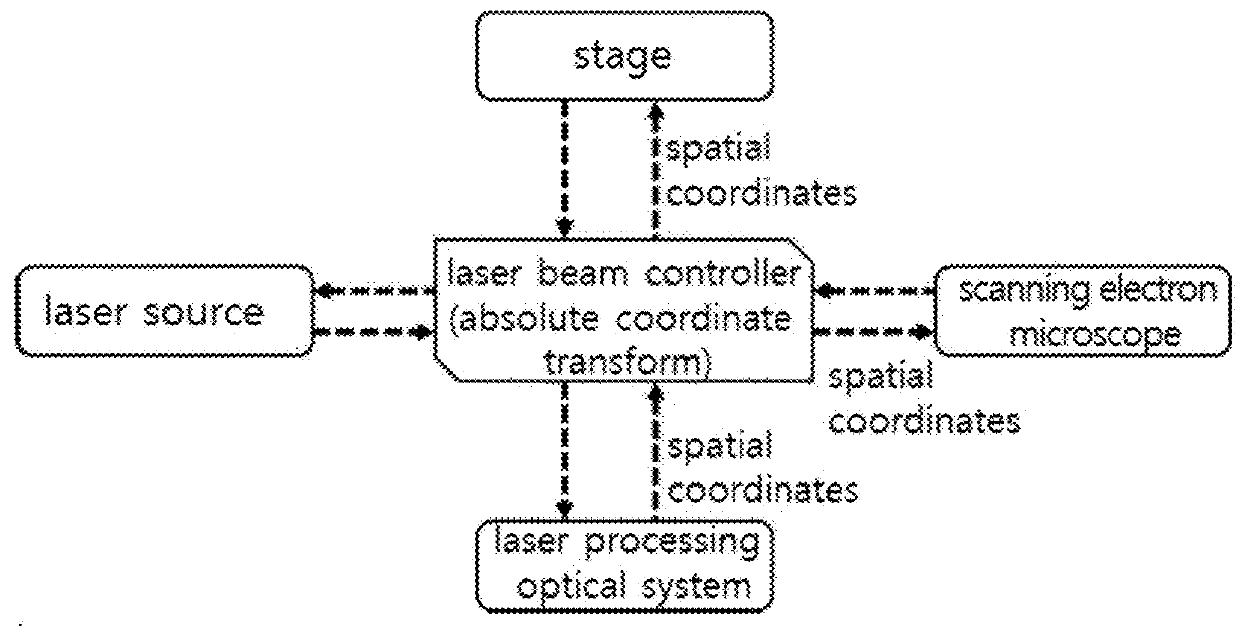

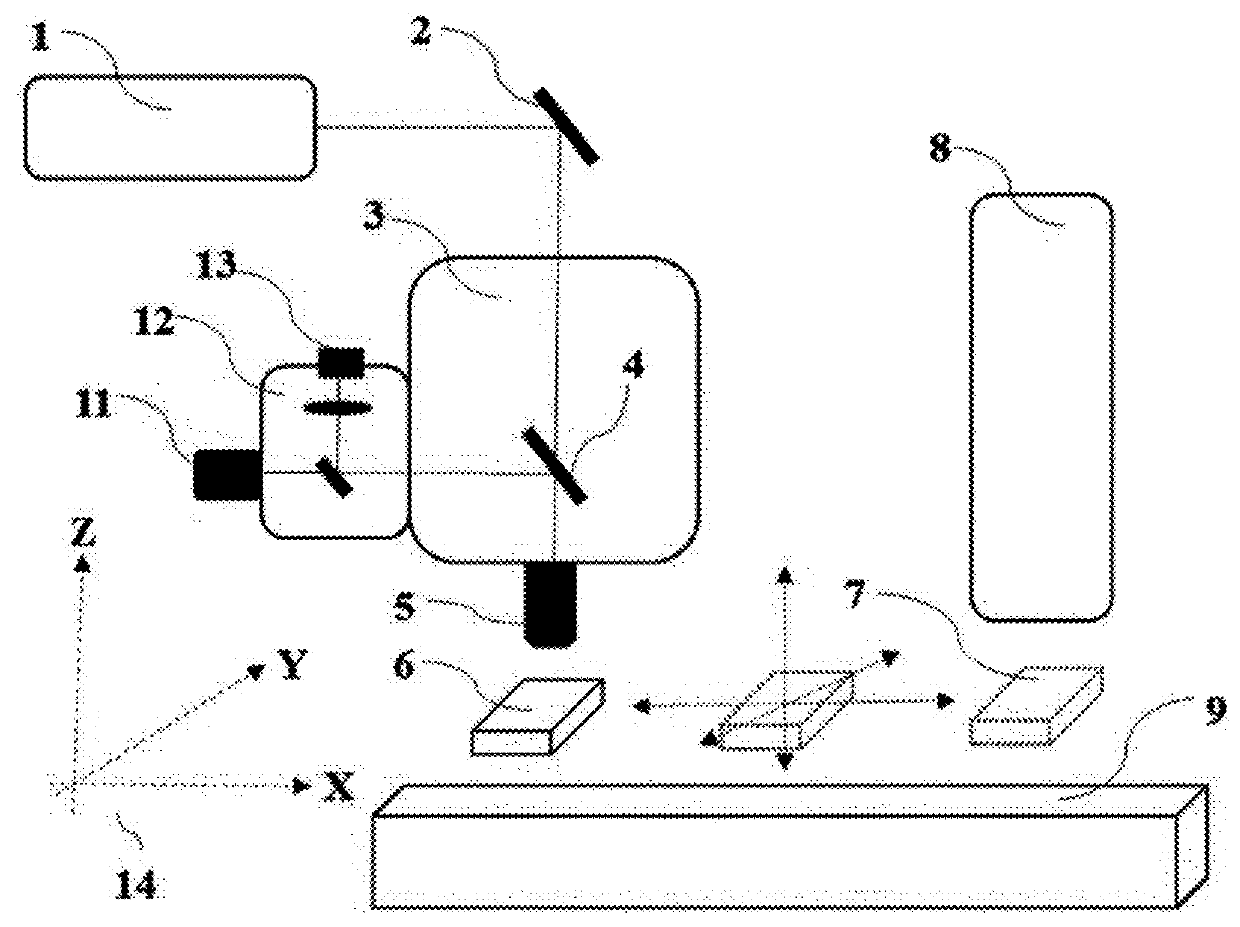

Method and device for modifying object to be processed by using ultrashort pulse laser

InactiveUS20180264592A1Limited timeEasily optimizeWelding/soldering/cutting articlesLaser beam welding apparatusUltrashort pulse laserScanning electron microscope

The present invention relates to a processing device for modifying a surface or an interior of an object to be processed by using an ultrashort pulse laser, the device including: a stage for loading an object to be processed; a laser beam radiating device including a laser source generating an ultrashort pulse laser beam, and a laser processing optical system for radiating laser beam toward the object to be processed loaded on the stage; a laser beam controller capable of setting a laser process condition and three-dimensional spatial coordinates of the object to be processed; and a scanning electron microscope through which the surface of the object to be processed is observed, and a method of modifying, by using the processing device, an object to be processed by cutting a part thereof or processing a surface thereof by using an ultrashort pulse laser.

Owner:LASERNICS

Audio signal processing method and device

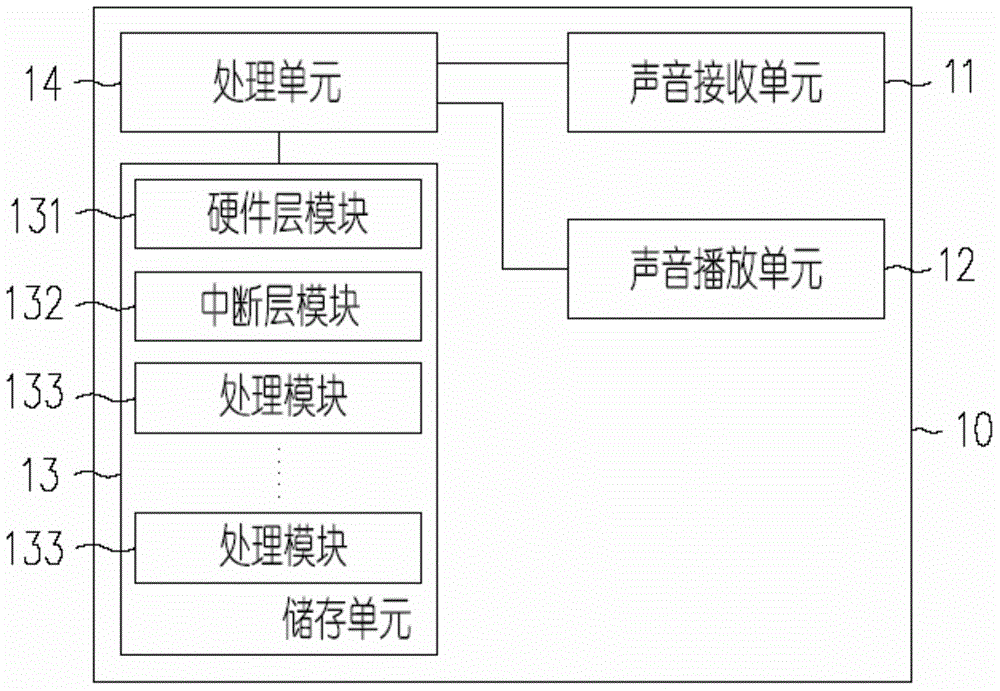

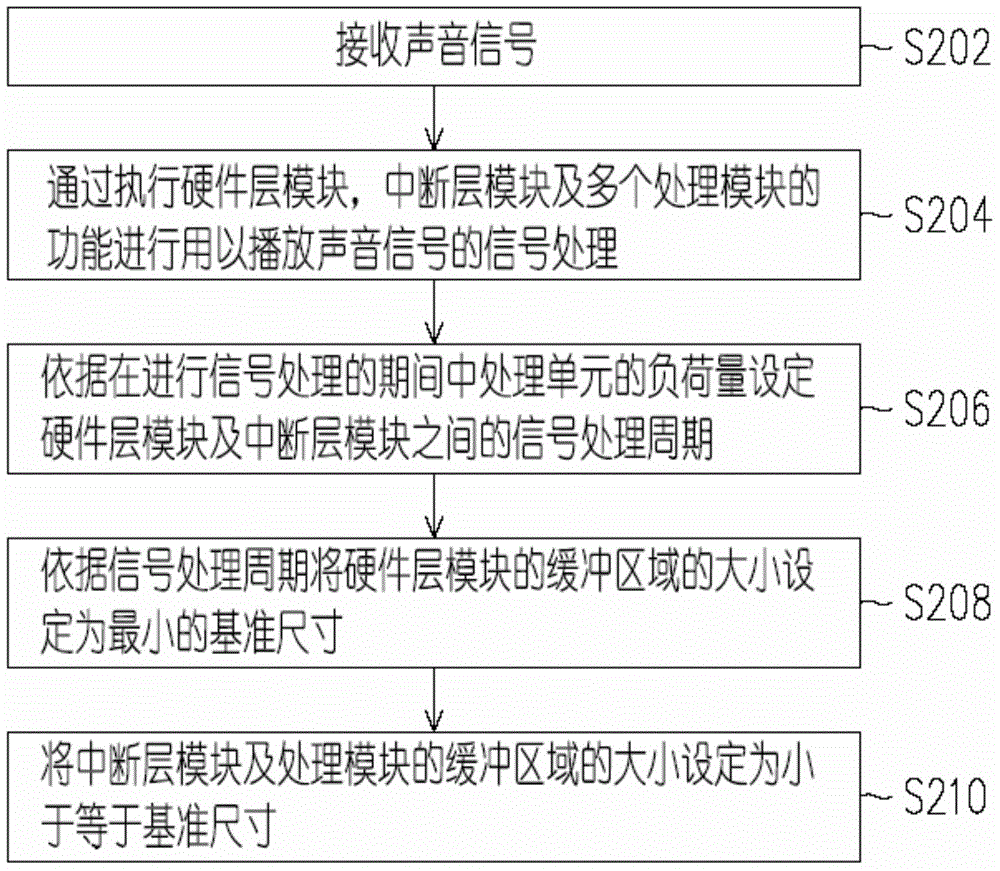

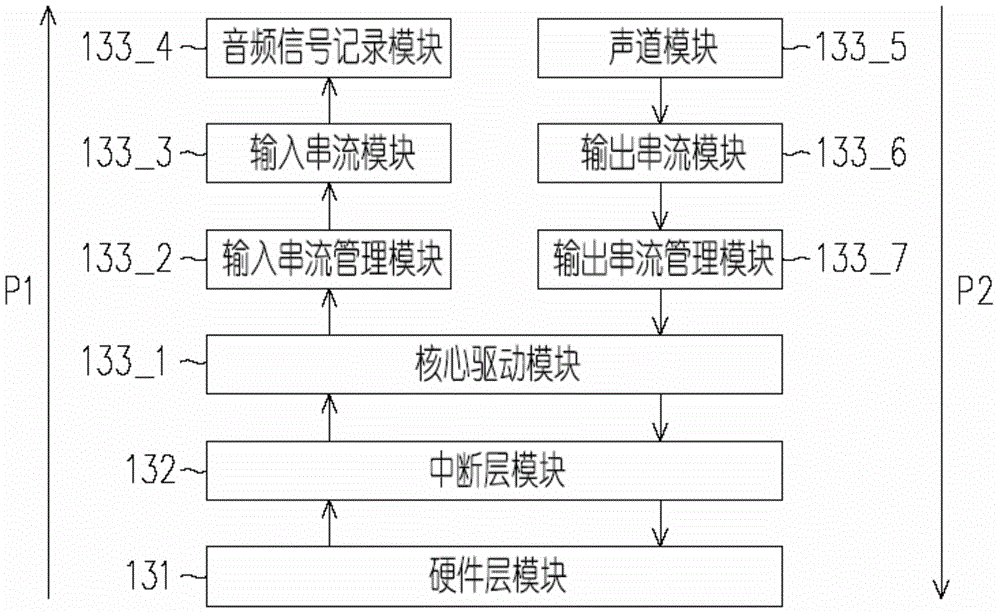

InactiveCN105792068AReduce processing timeLimited timeTransducer circuitsEmbedded systemLoad capacity

The invention discloses an audio signal processing method and device. The method comprises following steps of receiving a sound signal; processing the signal through executing functions of a hardware layer module, an interrupt layer module and multiple processing modules, thus playing the sound signal; according to the load capacity of the processing unit in an electronic device during the signal is processed, setting a signal processing period between the hardware layer module and the interrupt layer module; according to the signal processing period, setting the buffer size of the hardware layer module as the minimum reference size; and setting the buffer sizes of the interrupt layer module and the processing module to be less than or equal to the reference size.

Owner:ACER INC

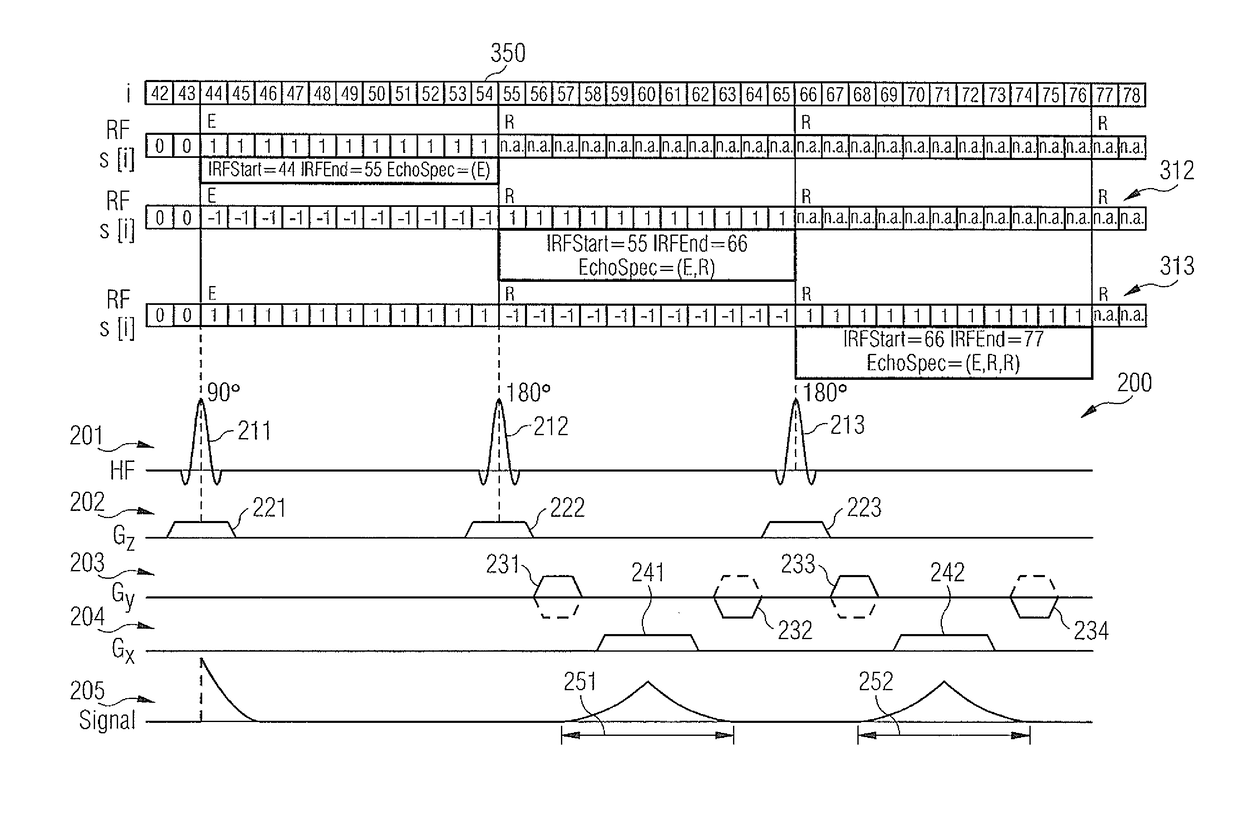

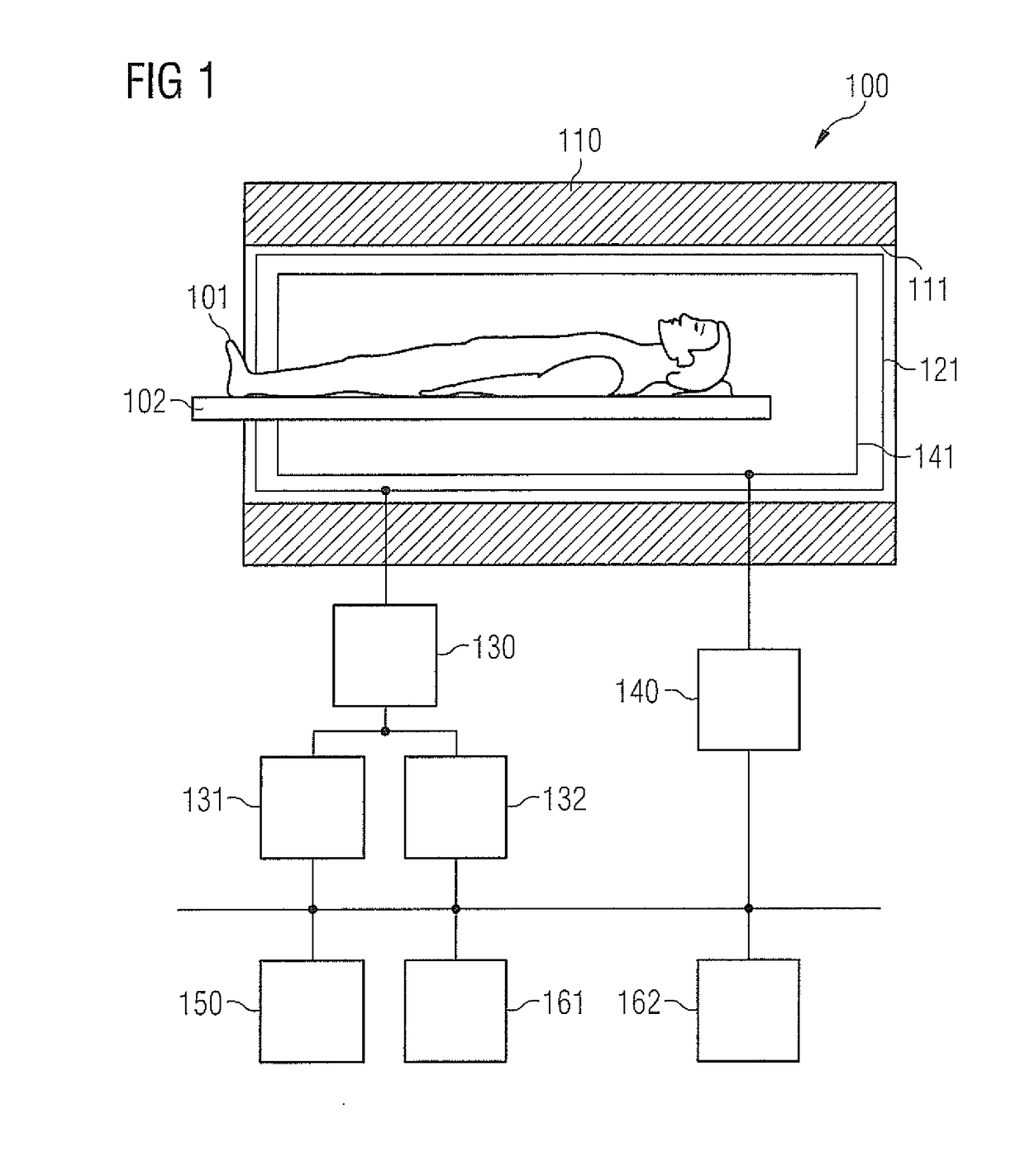

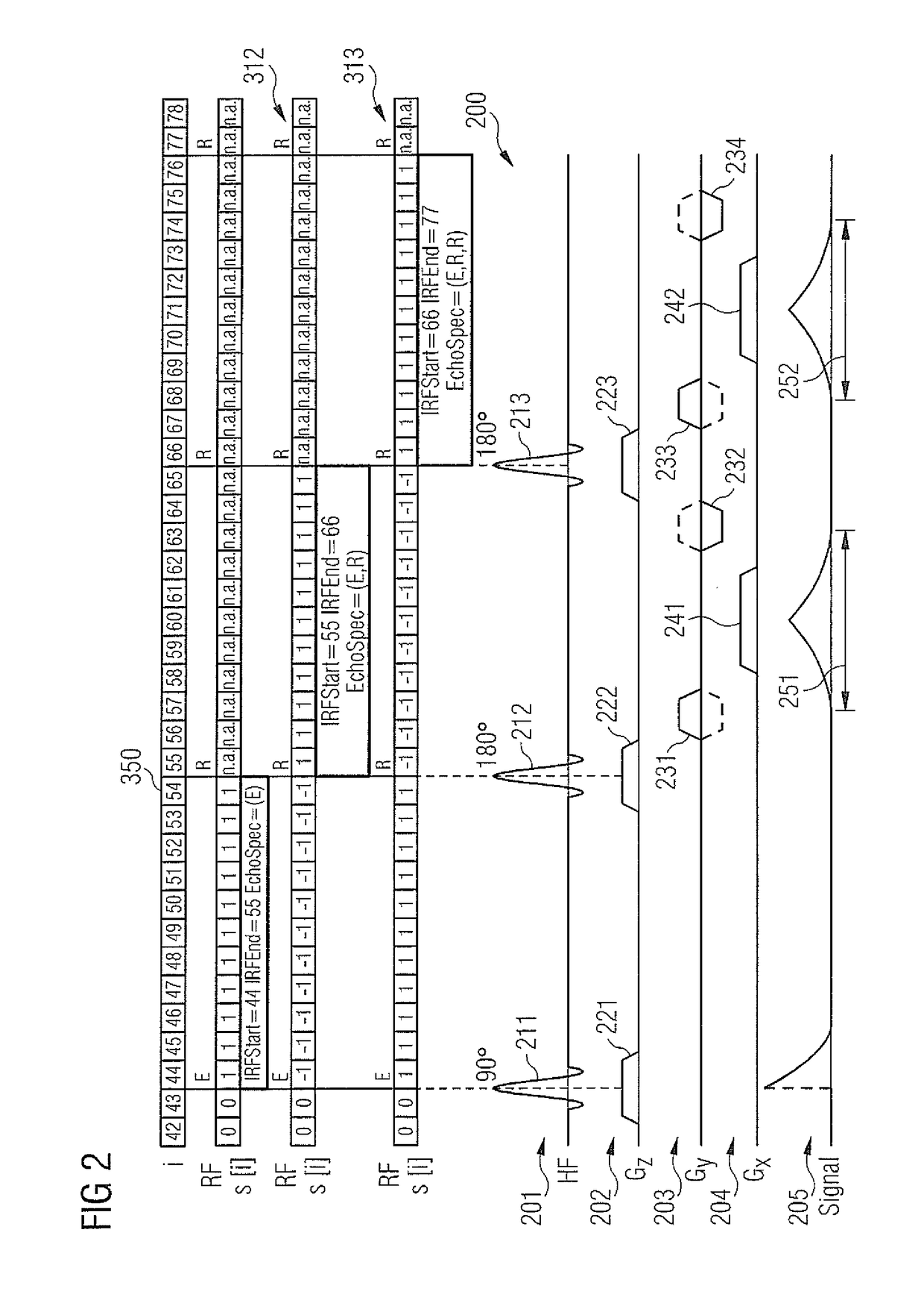

Method and magnetic resonance apparatus for determining a scan sequence based on a pulse response of the gradient system

ActiveUS20180120397A1Limited timeHigh spatial resolutionMeasurements using NMR imaging systemsNuclear magnetic resonanceMR - Magnetic resonance

In a magnetic resonance installation and a corresponding method, a scan sequence is determined based on a representation in k-space of a pulse response of a gradient system of the magnetic resonance installation.

Owner:SIEMENS HEALTHCARE GMBH

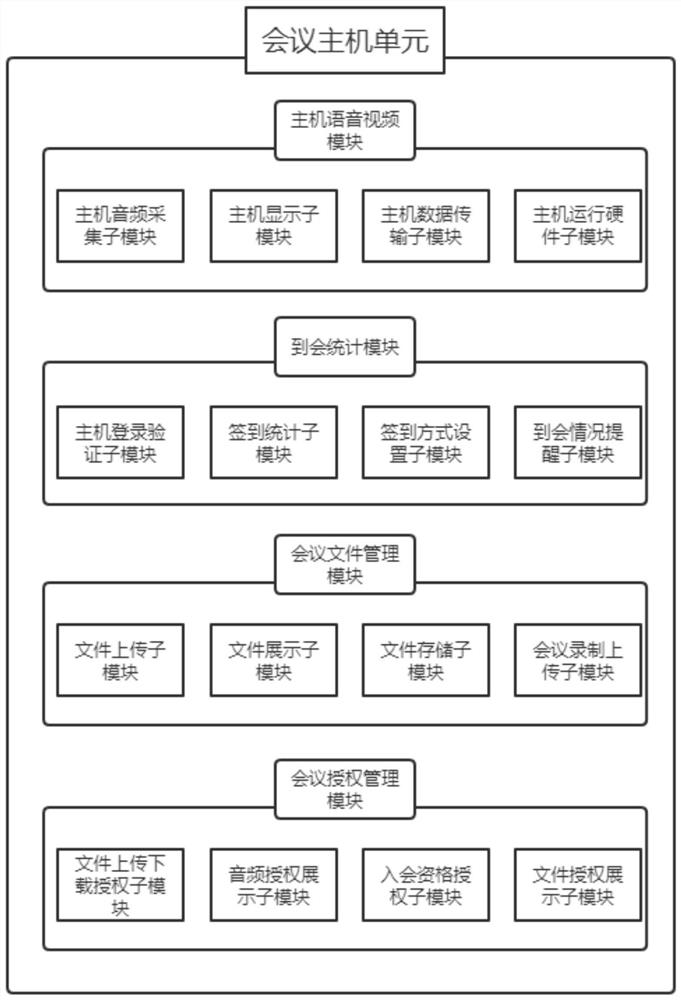

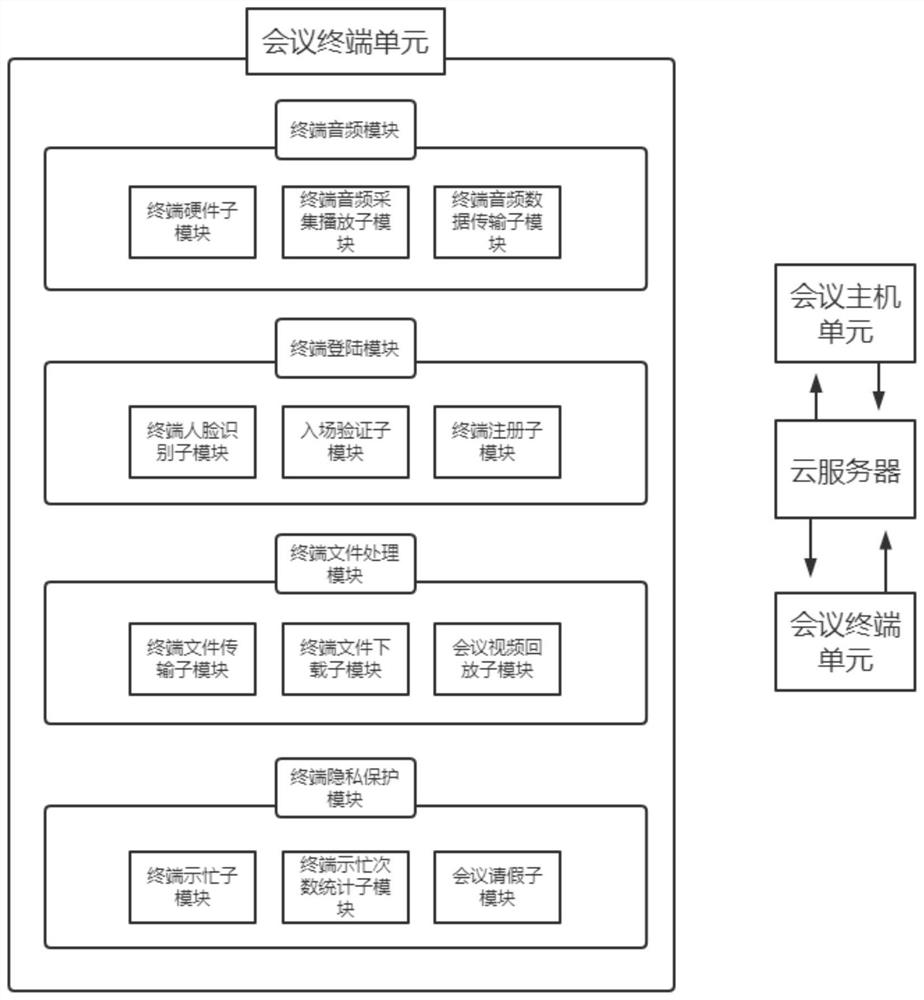

Remote collaborative conference system and working method thereof

PendingCN114222087AEasy to explainEasy to communicate and discussTelevision conference systemsOffice automationEngineeringKnowledge management

The invention discloses a remote collaborative conference system and a working method thereof, and relates to the technical field of remote conferences. In order to solve the problem that corresponding documents and pictures cannot be displayed on a conference picture in real time so that people participating in a conference can clearly contrast and check the documents and the pictures. The system specifically comprises a conference host unit, a conference terminal unit and a cloud server, wherein the conference host unit comprises a host voice and video module used for processing videos and voices during a conference, and an arrival statistical module used for performing statistics on personnel arrival conditions; the working method of the system comprises the following steps: a conference host shoots pictures and sounds of a conference site through the host audio acquisition sub-module, and uploads conference files through the file uploading sub-module. According to the invention, both the conference host and the conference participants can upload and download the files related to the conference, and the corresponding files are displayed through the file display sub-module, so that the participants can report related problems in detail.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

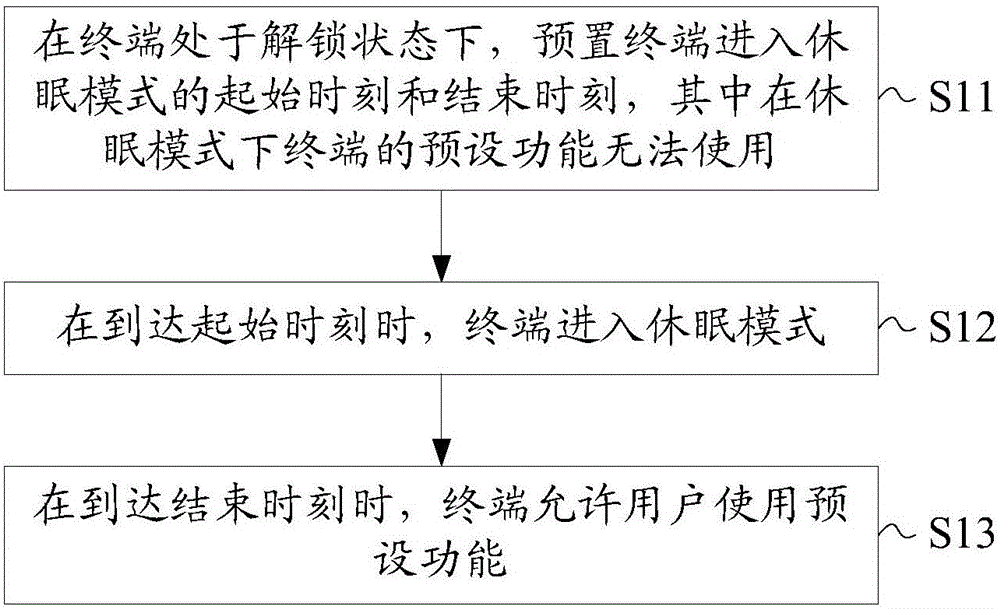

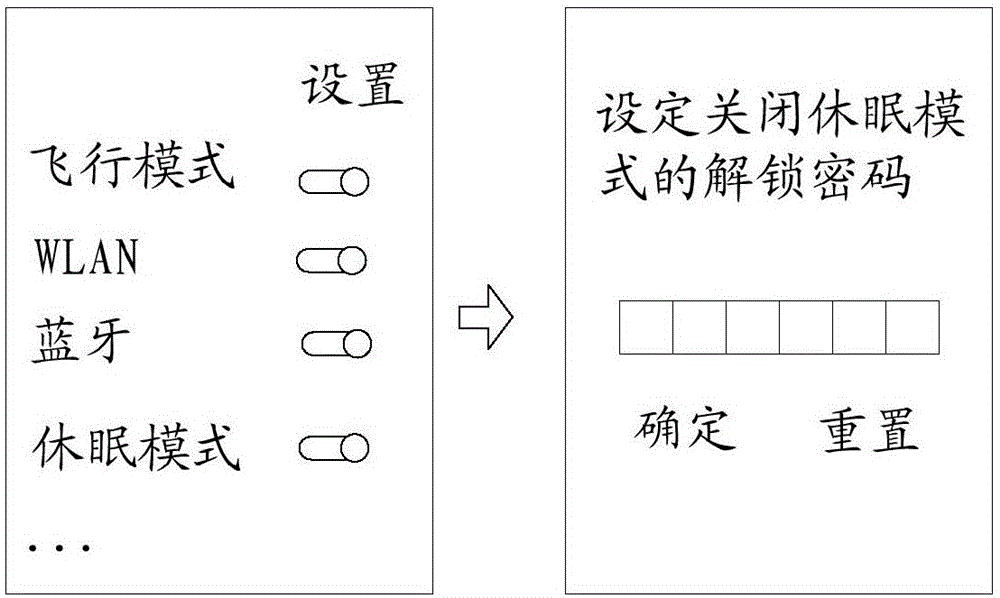

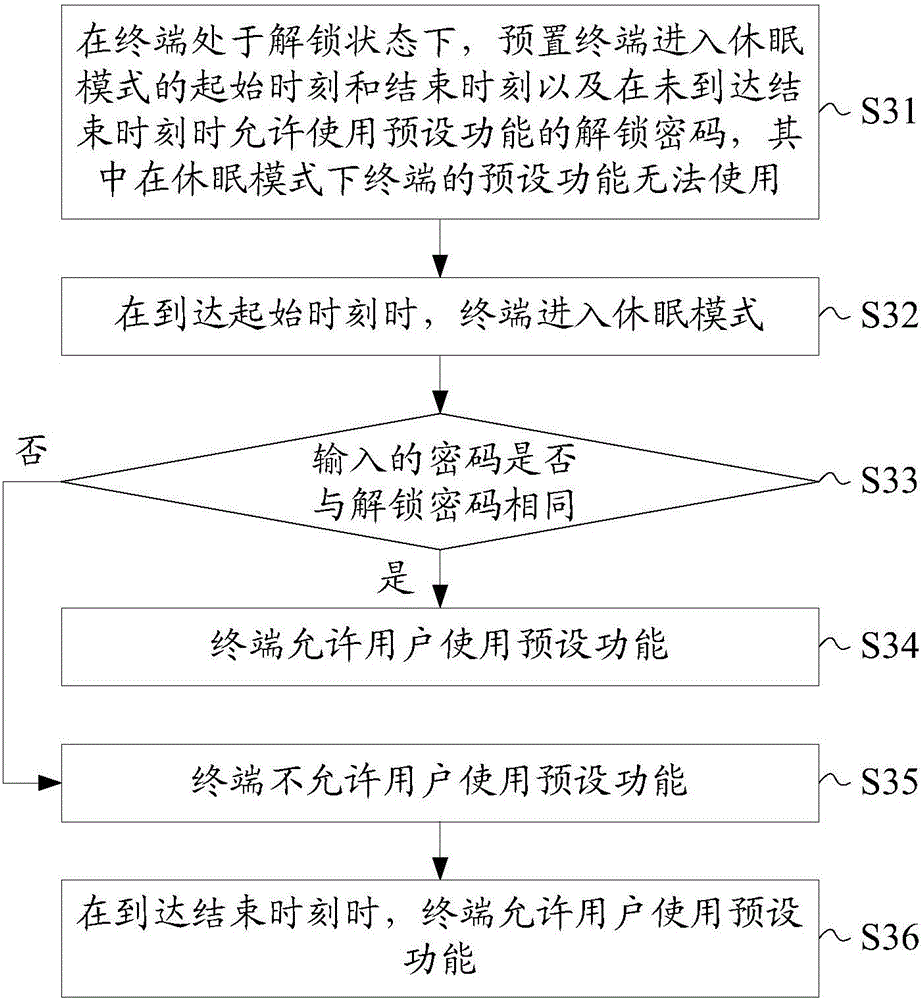

Terminal and method for automatically entering sleep mode of terminal

The invention discloses a terminal and a method for automatically entering a sleep mode of the terminal. The method comprises the steps of pre-setting a start moment and a finish moment of the terminal entering the sleep mode when the terminal is in an unlock state, wherein the preset function of the terminal in the sleep mode cannot be used; enabling the terminal to enter the sleep mode when the start moment is reached; and allowing a user to use the preset function by the terminal when the finish moment is reached. By the terminal and the method, the time of the user for using electronic equipment such as a mobile phone can be limited, and a good health is promoted.

Owner:JRD COMM (SHENZHEN) LTD

LF refining method of low-carbon steel

PendingCN113088628AEasy to standardize operationReduce the influence of human factorsProcess efficiency improvementCarbide siliconSlag

The invention relates to an LF (ladle furnace) refining method of low-carbon steel. The comprises the following steps that 1) the endpoint carbon of a primary smelting furnace is controlled to be 0.07-0.09%, and alloy and slag charge are added into the steel along with steel flow in the tapping process of the primary smelting furnace; 2) after molten steel reaches a refining position, power supply begins, silicon carbide and a carburant are added for diffusion deoxidation, and argon is blown at the bottom of a large ladle; and (3) after slagging, power is shut off, argon bottom blowing is conducted for stirring, a primary sample is taken for analysis, the result is analyzed, the content of molten steel components is adjusted according to the targeted component requirement, then argon bottom blowing is conducted for stirring, sampling analysis is conducted again till the components of the molten steel meet the targeted component requirements, and then tapping is conducted to obtain the low-carbon steel. According to the method, the using amount of deoxidizing materials such as the carburant and silicon carbide and the using amount of the bottom blowing argon in the refining diffusion deoxidizing process are quantified, the influence of human factors is reduced, the problems that the using amount of the carburant and the silicon carbide is greatly changed and molten steel components are greatly fluctuated in the refining diffusion deoxidizing process of the molten steel are solved, and standardized operation of the molten steel in the refining process can be facilitated.

Owner:SHANDONG IRON & STEEL CO LTD

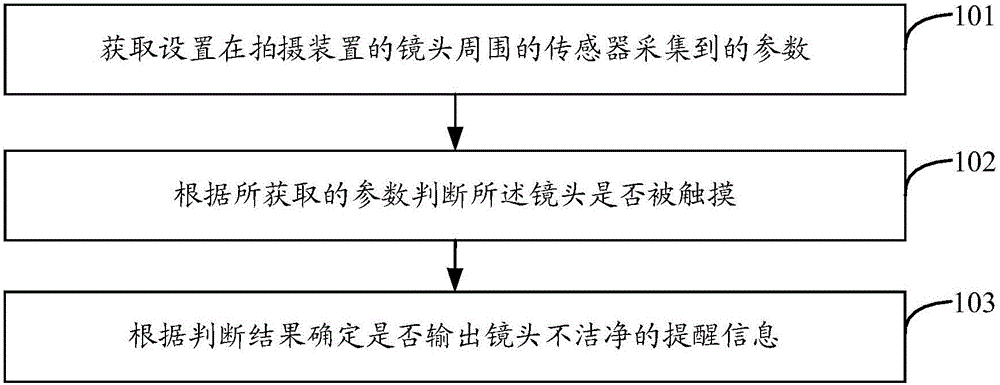

Information reminding method and apparatus

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

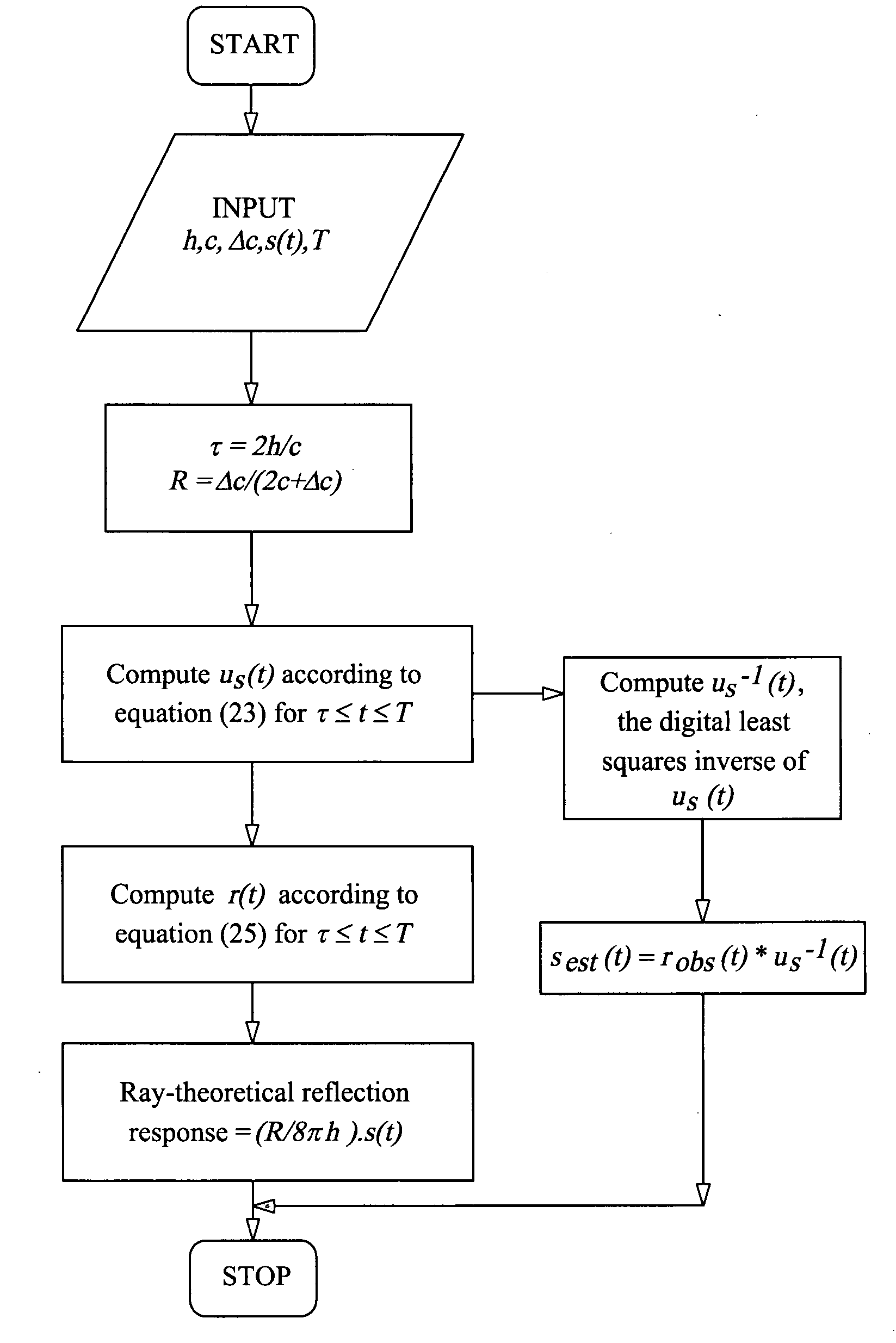

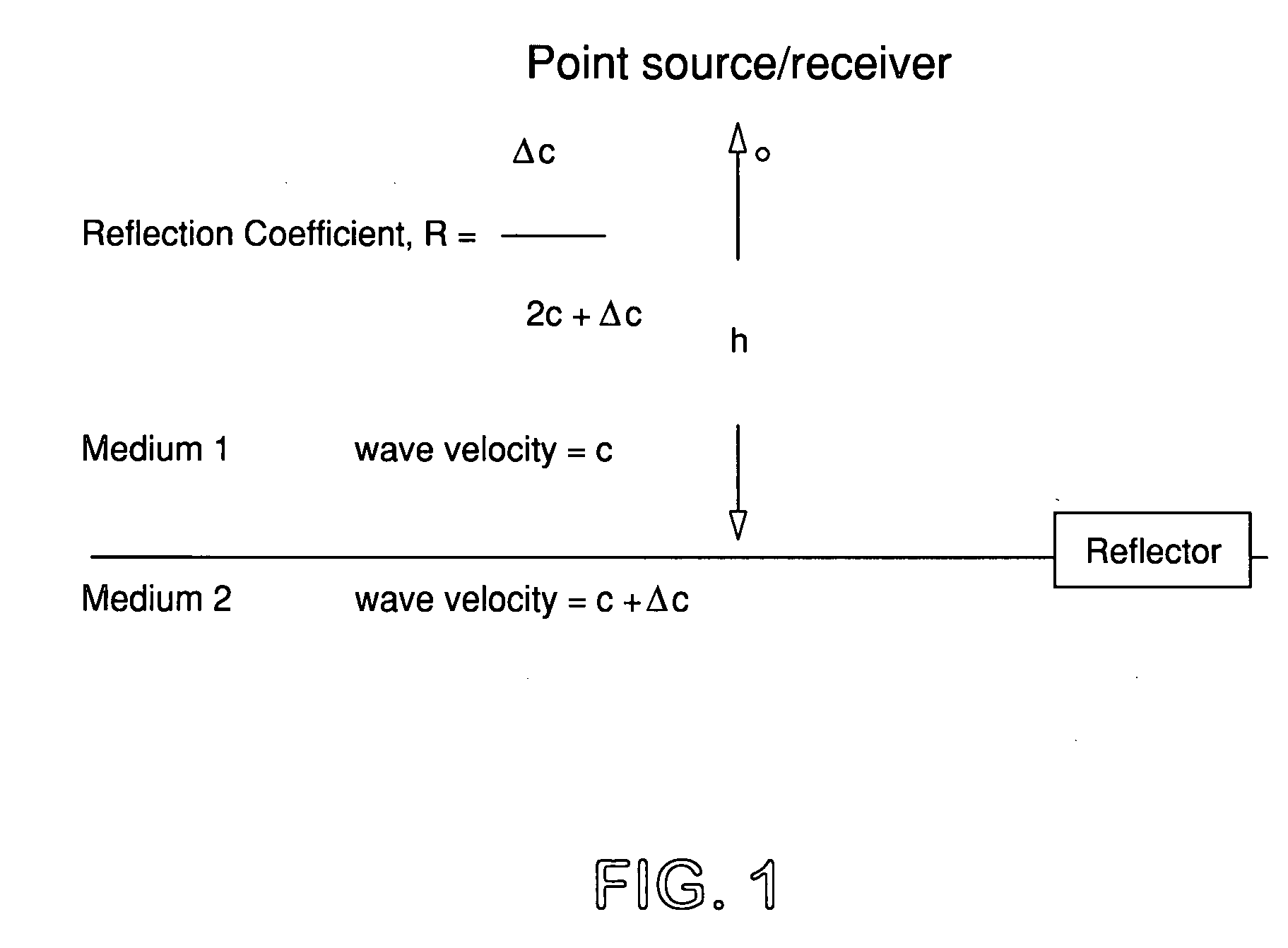

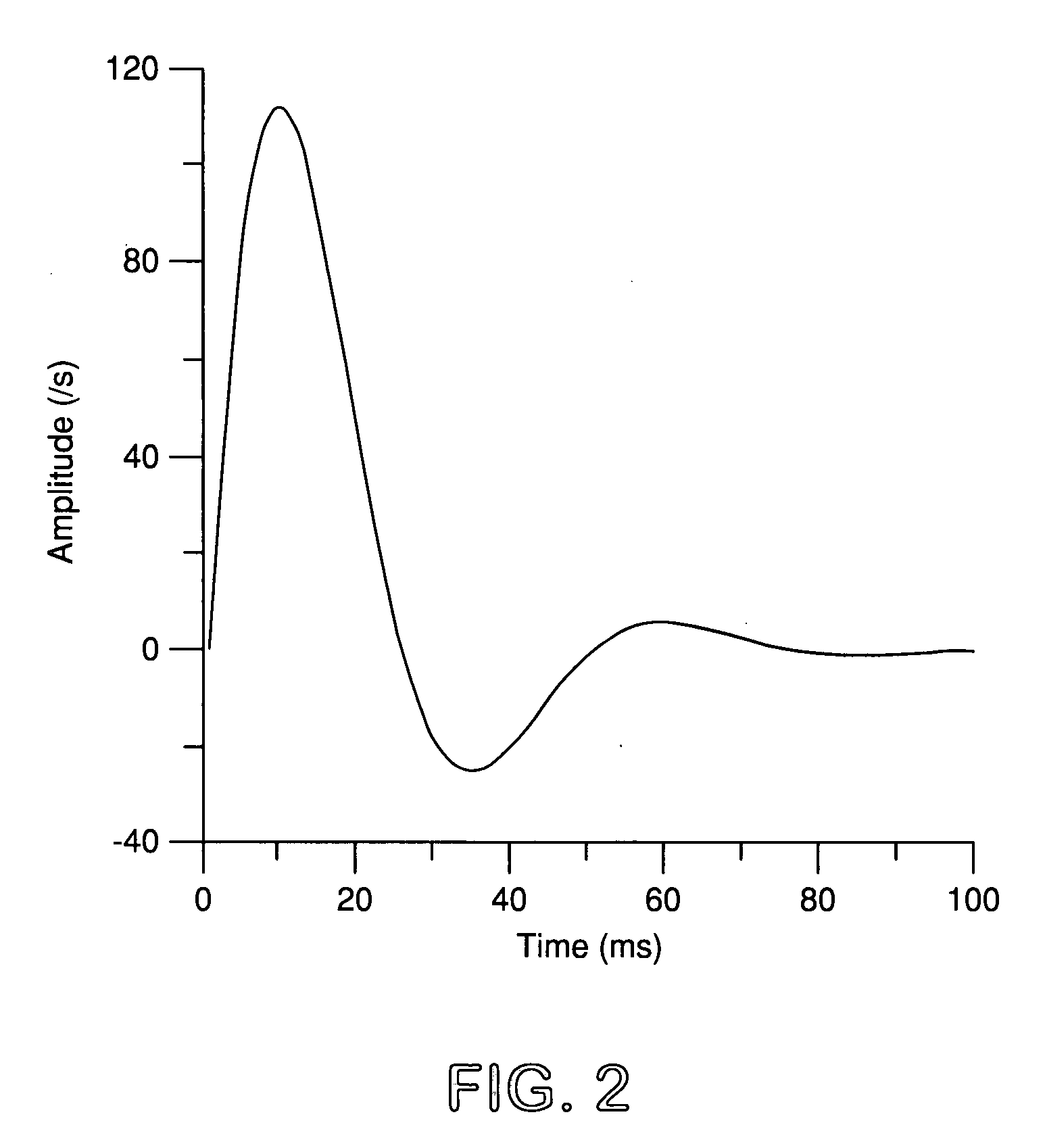

Method for computing an exact impulse response of a plane acoustic reflector at zero offset due to a point acoustic source

Originating from a novel and an exact algebraic formula for the impulse response of a plane acoustic reflector at zero offset due to a point acoustic source the present invention provides a method for computing an exact impulse response of a plane acoustic reflector at zero offset due to a point acoustic source; and originating from the method, methods for testing and validating algorithms for numerical modeling of seismic reflection, seismic migration and seismic inversion; a method for testing the efficacy of ray-theoretical solution for a given source-reflector configuration; another method for computing zero-offset reflection response of a circular reflector at its central axis; yet another method for validating an interpretation of a reflector as a planar structure; still yet another method for estimating the seismic source-time function when the zero-offset reflection response of a plane reflector is given. Although the algebraic formula and the methods originating from it are, in a strict sense, valid for an acoustic earth and an acoustic source, these would also be of immense utility in the seismic industry where the earth is successfully approximated as an acoustic medium and a seismic source as an acoustic source.

Owner:COUNCIL OF SCI & IND RES

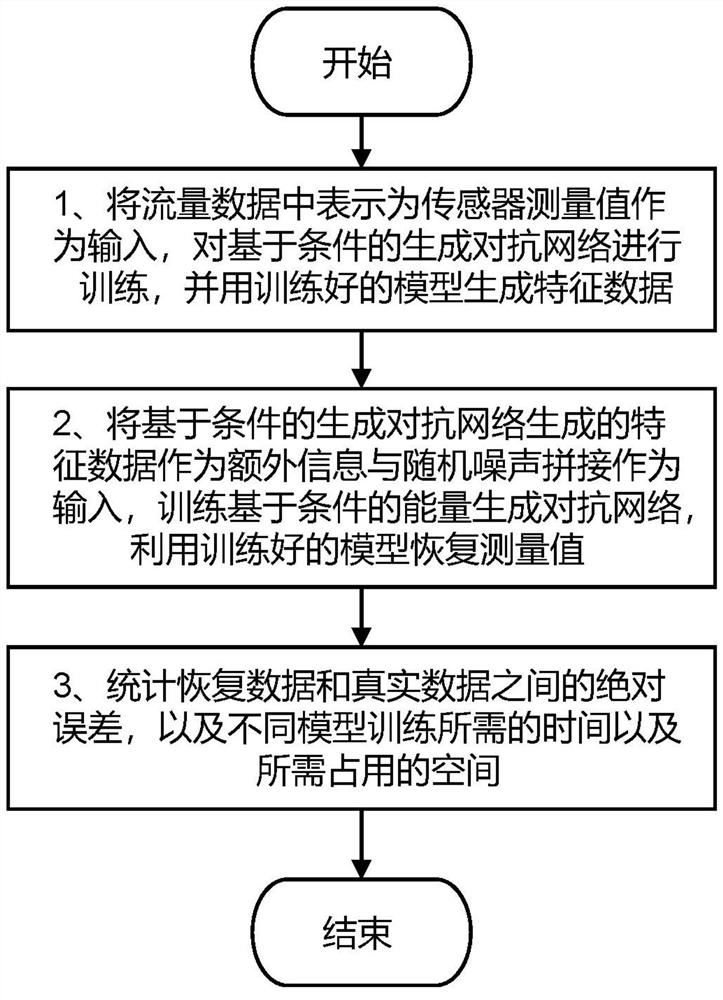

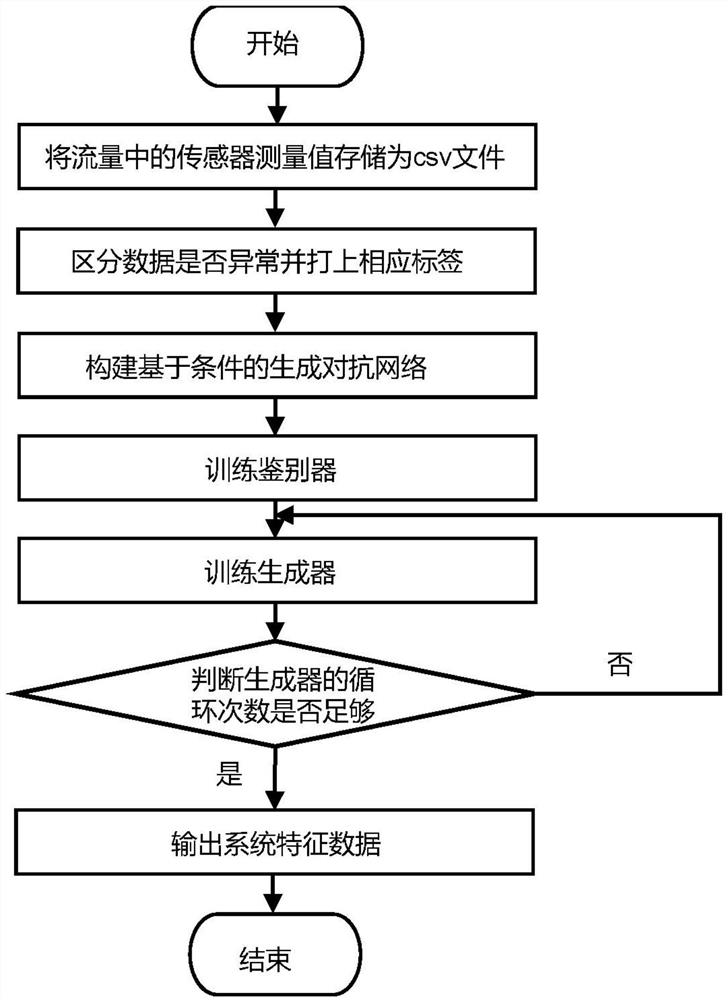

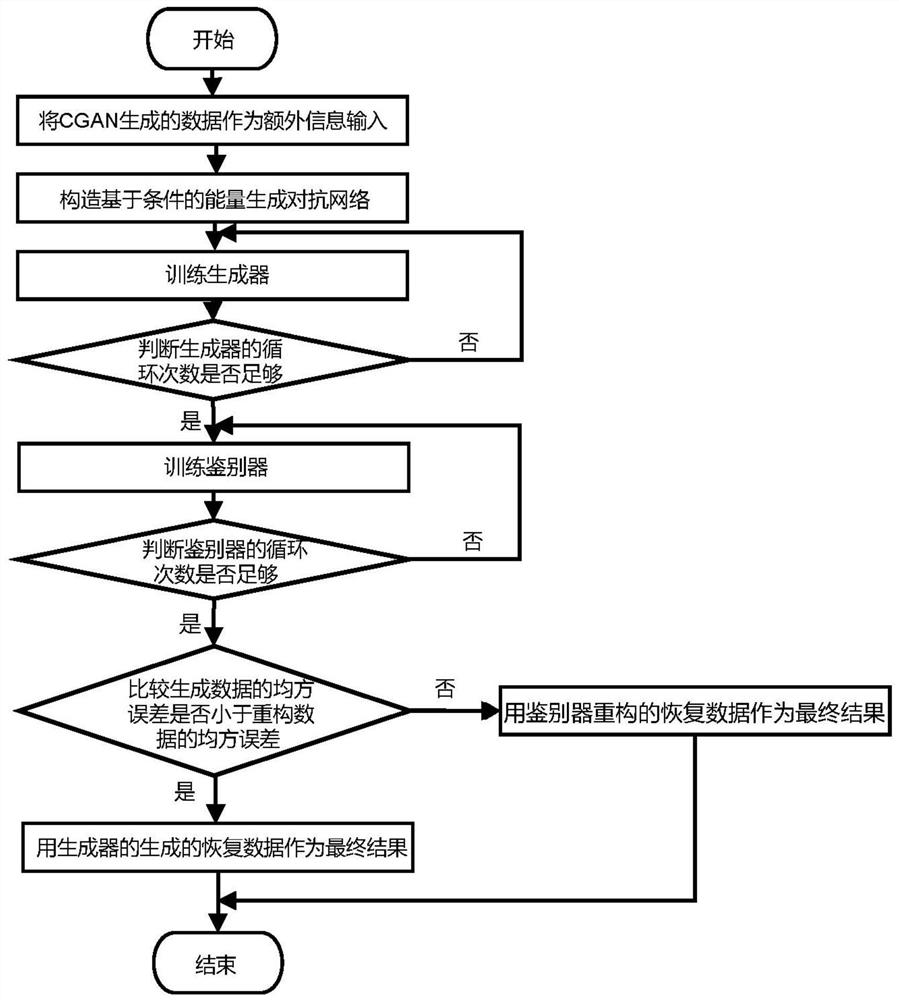

Network attack recovery method of cascaded condition-based energy generative adversarial network

PendingCN113806734AAchieve the effect of operationAchieving Recovery AccuracyPlatform integrity maintainanceNeural learning methodsDecision strategyGenerative adversarial network

The invention discloses a network attack recovery method for a cascaded condition-based energy generative adversarial network, which comprises the following steps of: representing a sensor measurement value in flow data as input, and generating feature data by using a trained model; taking feature data generated by the trained condition-based generative adversarial network as additional information and splicing with random noise to serve as input; calculating the absolute error between the recovery data and the real data, and the time required by different model training and the space required to be occupied, and measuring the performance difference between different models by using the indexes. The condition-based generative adversarial network model used in the method can quickly simulate behavior features during system schedule operation, the proposed condition-based energy generative adversarial network can effectively improve the recovery precision of the measured value, and the designed adaptive decision strategy can improve the recovery stability of the measured value. And the possibility of generating abnormal points is reduced.

Owner:BEIJING UNIV OF TECH

Vein searching instrument and using method thereof

The invention discloses a vein searching instrument and a using method thereof. The vein searching instrument comprises a light source used for determining the position of a vein, and a shell covering the light source, wherein a triggering unit connected with the light source is arranged on the shell and used for identifying the using state of the vein searching instrument and controlling on-off of the light source. The vein searching instrument has the remarkable advantages that the triggering unit is arranged to identify the using state of the vein searching instrument and control on-off of the light source, so that the vein searching instrument only emits light when used; the light source used for irradiating skin, soft tissue and bones in a passing-through mode is arranged, so that vein vessels are easy to find, positioning is accurate, and vessel puncturing can be assisted; a fixing device is arranged, so that the vein searching instrument is convenient to wear and convenient and quick to use; cost is low, and popularization is easy; operation is easy, diversified switching modes of the light source are available, and requirements for touch control and light sensitization are met; a programmable controller is arranged so that using frequency and using time can be limited and the state of a power supply can be monitored.

Owner:SUZHOU LINHWA MEDICAL DEVICES CO LTD

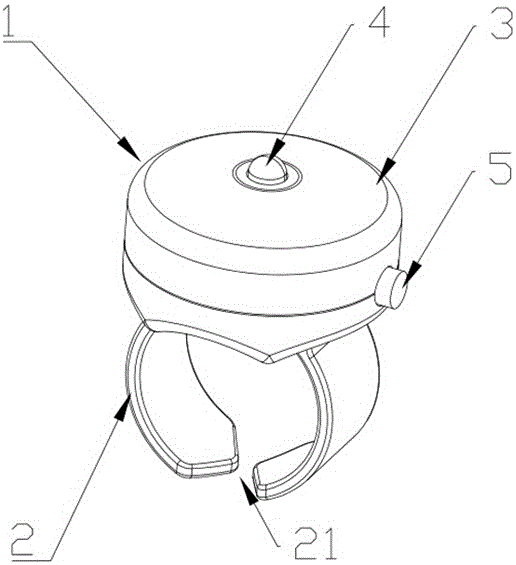

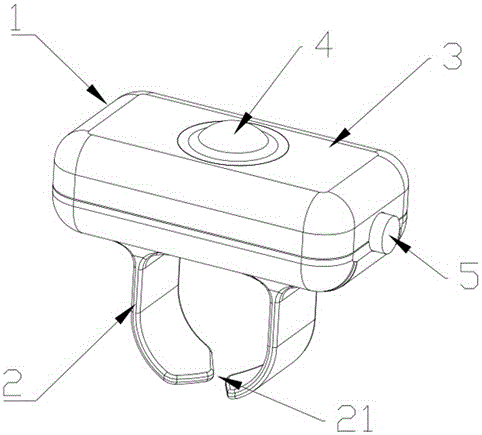

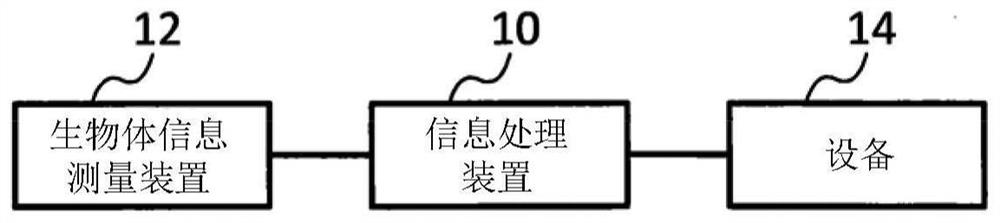

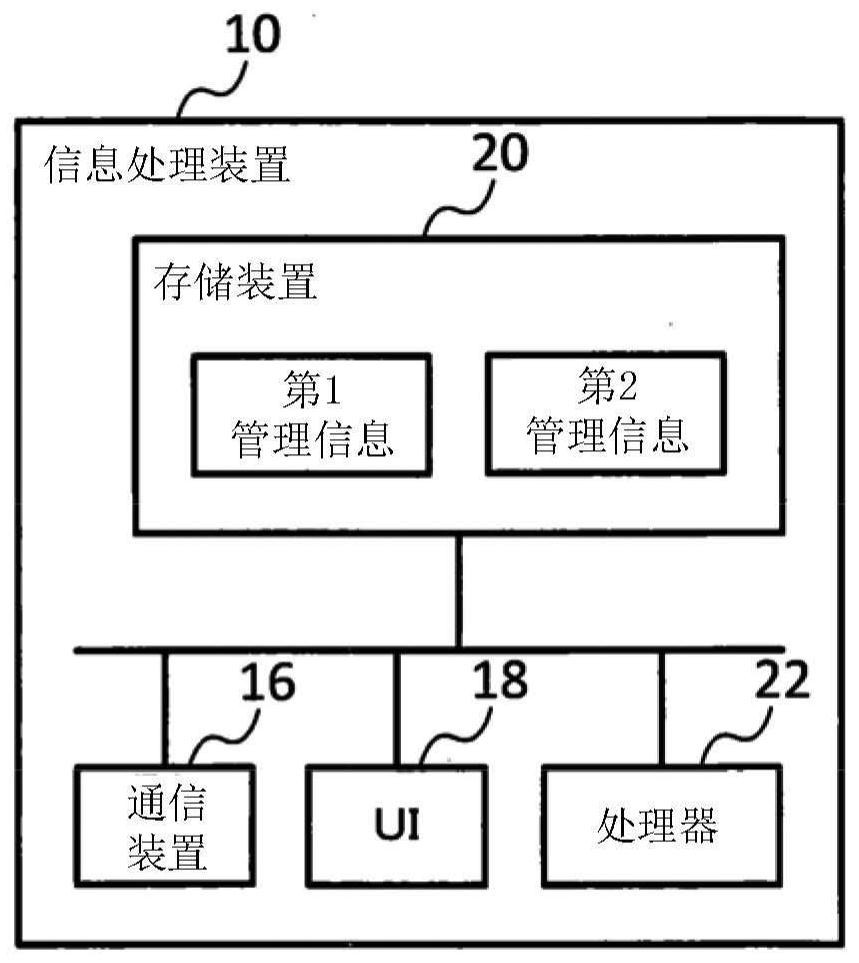

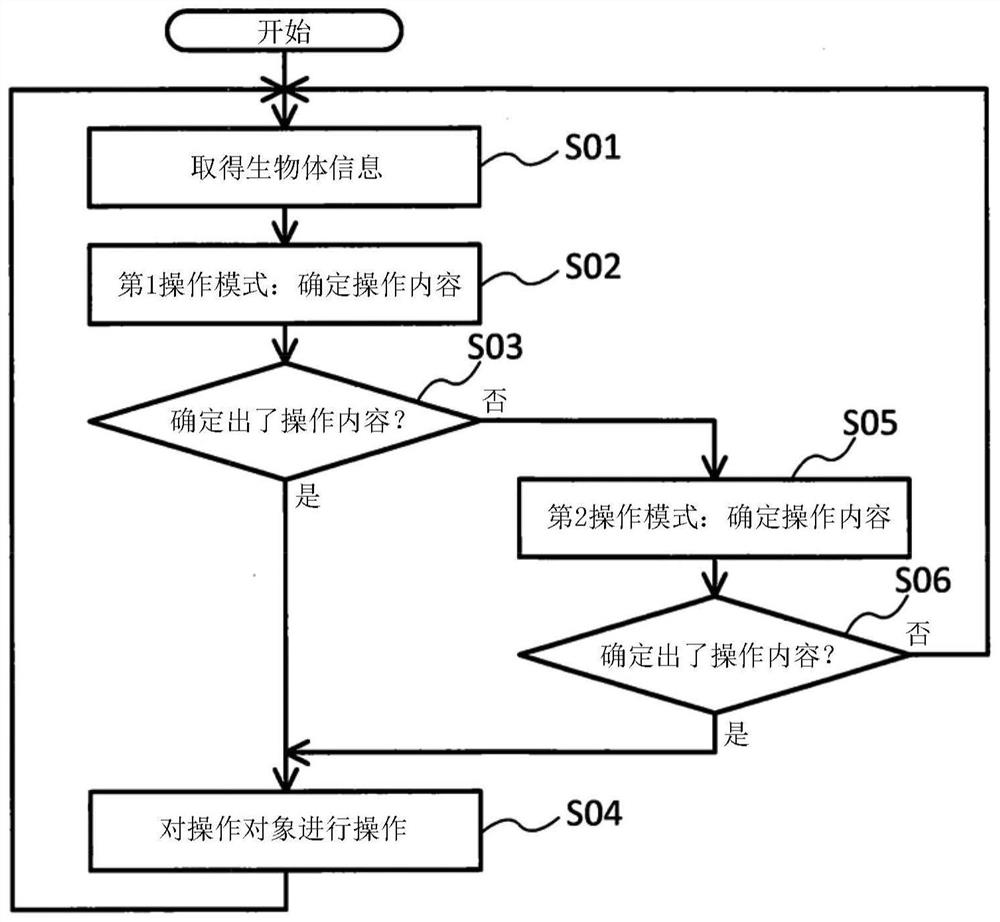

Information processing device and computer readable medium

PendingCN112987911ALimited timeInput/output for user-computer interactionMechanical apparatusComputer hardwareInformation processing

The invention provides an information processing device and a computer readable medium. The information processing device includes a processor configured to operate an operation target according to a first operation mode on a basis of biological information about a user, and operate the operation target according to a second operation mode different from the first operation mode on a basis of the biological information about the user in a case where biological information about the user is being measured and the operation target is not operated according to the first operation mode on the basis of the biological information about the user for a predetermined time or longer.

Owner:AGAMA X CO LTD

Locking device of television

InactiveCN101552892AReasonable structural designEasy to useTelevision system detailsColor television detailsHuman controlCable television

Owner:潘传忠

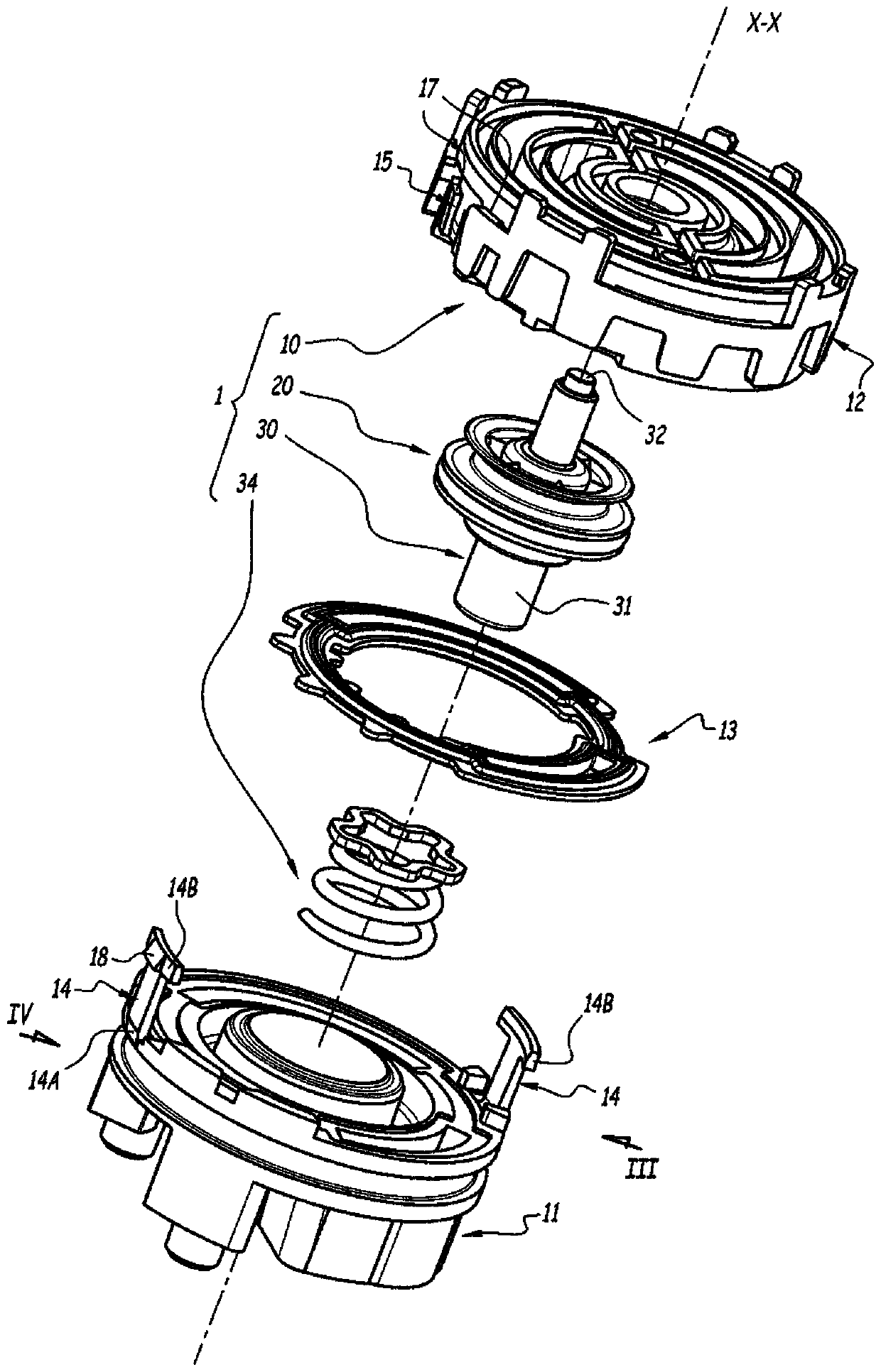

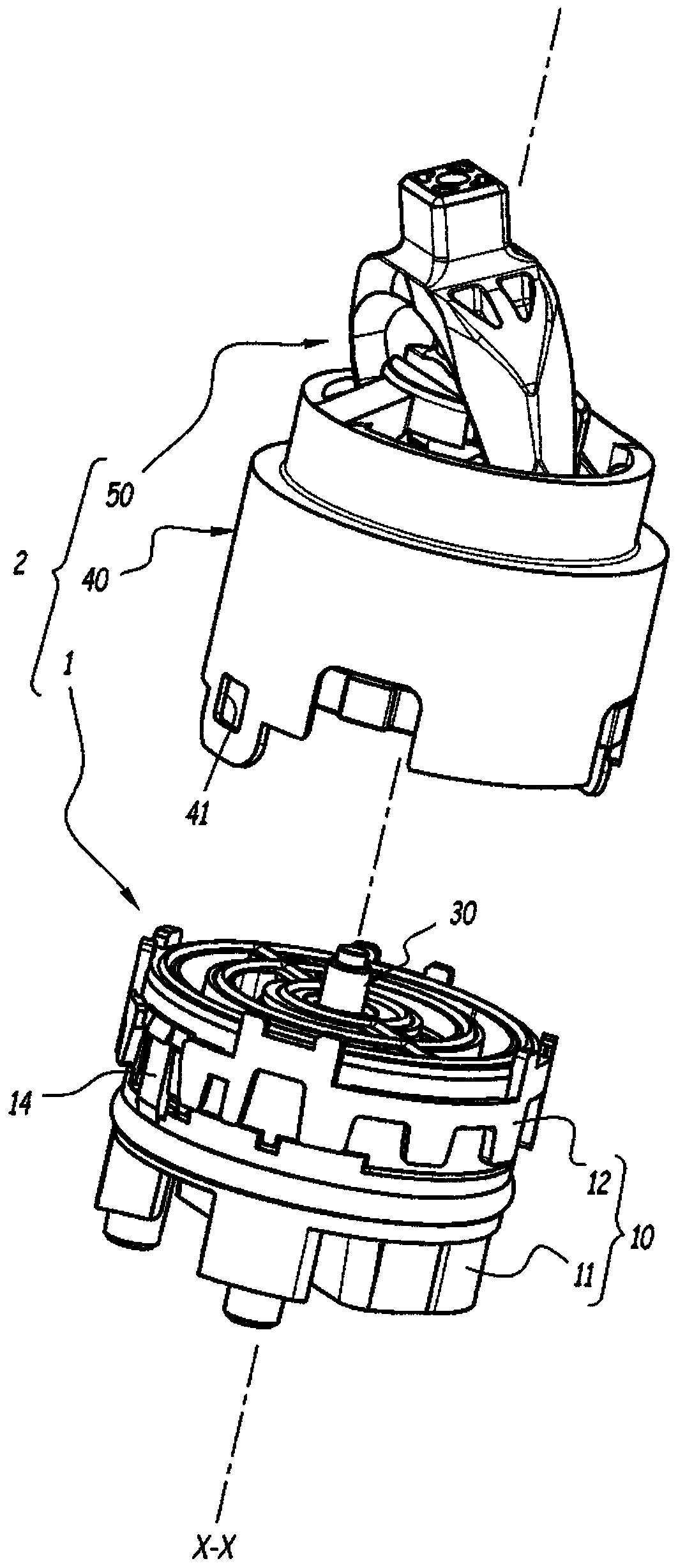

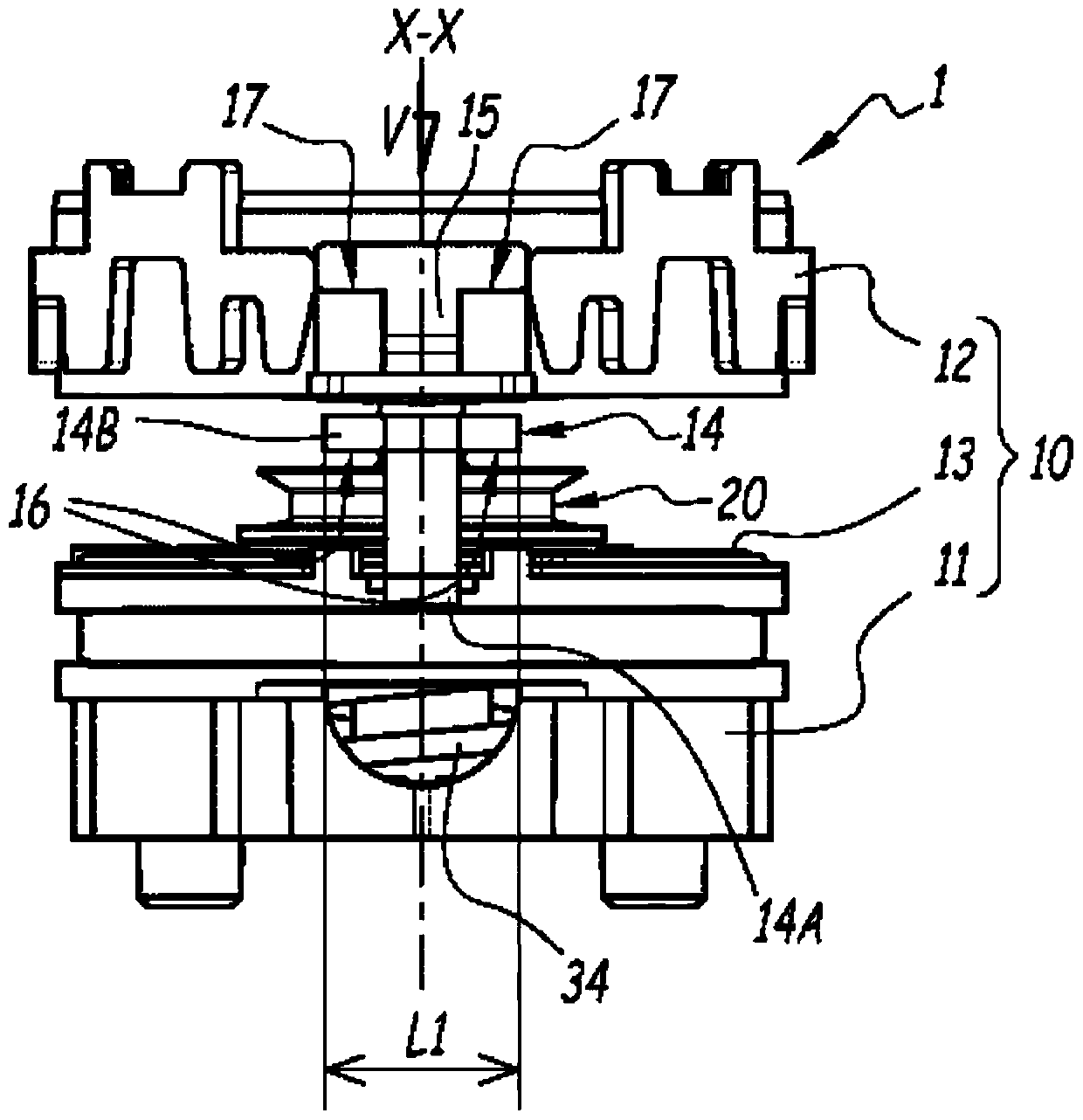

Thermostatic cartridge for regulating cold and hot fluids to be mixed

ActiveCN111201499AReliable holdLimited timeTemperature control without auxillary powerMultiple way valvesSpool valveControl system

A cartridge (2) comprises a base (10), a slide (20), a thermostatic actuator (30, 34), a cover (40), and a regulation and control system (50). The base comprises two base parts (11, 12) which, in an assembled state, are superimposed one against the other along an axis (X-X) with the interposition of a seal (13) and which jointly define a mixing chamber. The slide is movable in the chamber in orderto inversely vary the flow sections of two passages, which are respectively supplied through one of the two base parts and which are delimited axially between the slide and respectively one and the other of the two base parts. The thermostatic actuator is arranged in the chamber and moves the slide to a regulation position as a function of the temperature of the mixture exiting the chamber. The cover is, in an assembled state of the cartridge, secured to the base. In order that this cartridge is fast and convenient to assemble, a first of the two base parts comprises at least one tab (14), which extends parallel to the axis, which, at a first axial end is connected to the rest of the first base part in both an axially fixed manner and a deformable manner to allow elastic deflection of thetab transversely to the axis, and which at its second axial end is provided with both at least one retaining surface, against which the second base part bears axially to hold the two base parts together, and a protruding relief (18) which is adapted to interact with the cover so that, during assembly between the cover and the base, the cover and the protruding relief slide against one another todeflect the tab towards the axis and, in the assembled state of the thermostatic cartridge, the protruding relief engages a hole (41) of the cover to axially retain the cover relative to the base.

Owner:VERNET SA

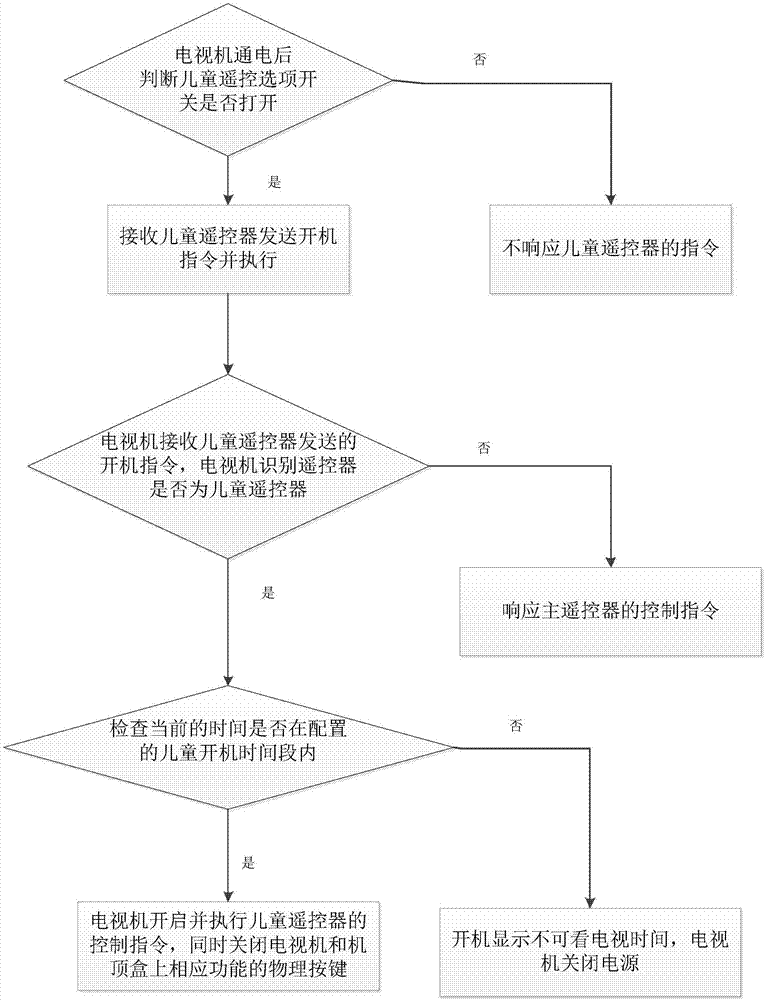

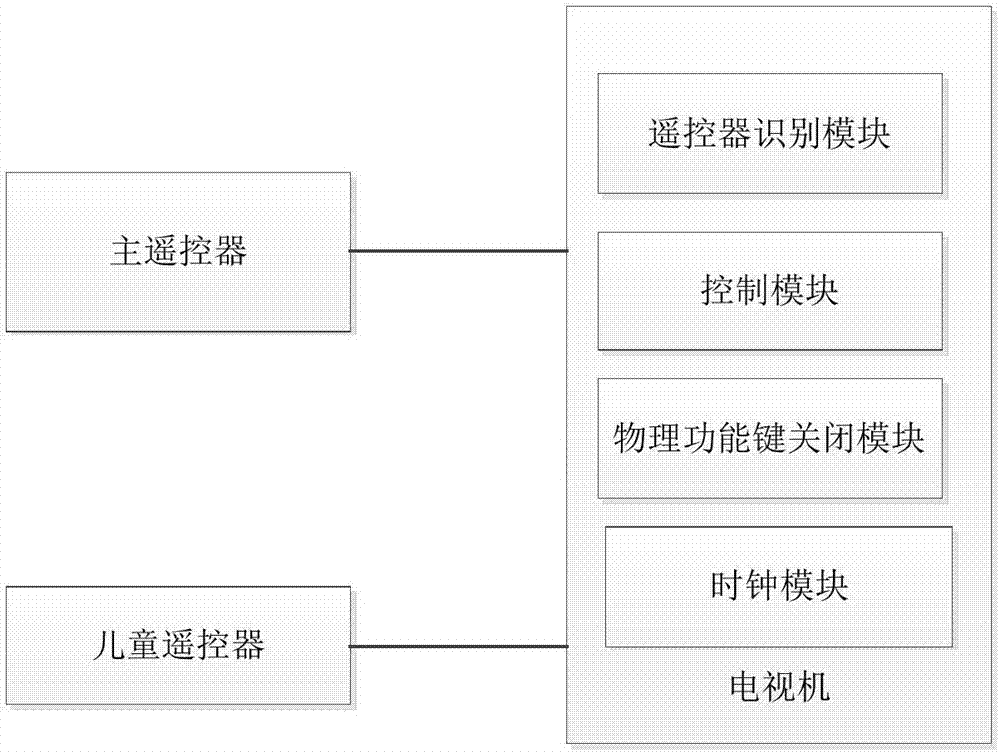

Remote control method and system for programmable children remote controller

InactiveCN107249143ALimited timeRestricted contentSelective content distributionRemote controlProgrammable logic controller

The invention relates to a remote control method for a programmable children remote controller. The method comprises steps that A, whether a children remote control option switch is open is determined after a TV is electrified, if yes, a power-on instruction sent by a children remote controller is received and is further executed; if not, the instruction of the children remote controller is received, and no response is carried out; B, the power-on instruction sent by the children remote controller is received by the TV, whether a remote controller is the children remote controller is identified by the TV, if yes, whether the present time is in the configured children power-on time interval is checked, if yes, the TV starts, the control instruction of the children remote controller is executed, and physical buttons of corresponding functions of the TV are further closed, if not, power-on display is the no TV time, a power source of the TV is turned off, if the remote controller is not the children remote controller, response to a control instruction of a main remote controller is carried out. The method is advantaged in that remote control on the TV is realized through the children remote controller for function restrictions, the TV watch time and contents of children and teenagers can be effectively monitored and limited, and physical and mental health is guaranteed.

Owner:胥红伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com