Electrolytic aluminium crust breaking cylinder feedback valve

A shelling cylinder and feedback valve technology, which is applied in the field of electrolytic aluminum shelling cylinder feedback valve, can solve the problems of unable to monitor the state of the cylinder and affect the purity of aluminum liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

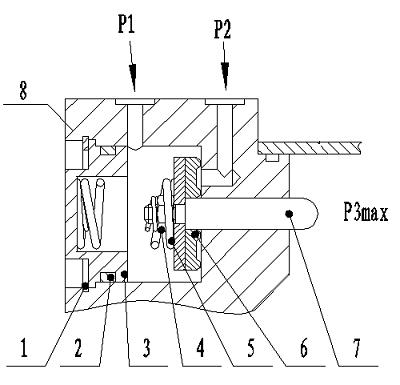

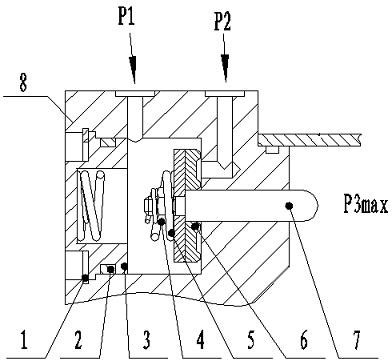

[0010] Such as figure 1 As shown in the figure, the electrolytic aluminum shell shell cylinder feedback valve includes a retaining ring 1, an O-ring 2, a gland 3, a spring 5, a special seal 6 and a contact rod 7, and the O-ring 2 is installed in the groove of the gland 3. The gland 3 is fixed on the front cover 8 through the retaining ring 1, the spring 5 is installed in the counterbore of the gland 3, the special seal 6 is connected with the contact rod 7 through the nut 4, the pressure of P1 is 0.6MPa, and the pressure of P2 is 0MPa , the maximum pressure of P3 is 0.6MPa. This valve can be installed on the front cover of the shelling cylinder. The pressure P1 is connected to the air source, the pressure P2 is connected to the atmosphere, and the pressure P3 is connected to the rod cavity of the cylinder. When shelling, due to the action of pressure P1 and spring 5, the valve position does not move. When the shelling is over, the piston hits the contact rod 7, forcing P1 to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com