A cvi process method for preparing carbon/carbon crucible based on flow field optimization

A process method and carbon crucible technology are applied in the field of CVI process for preparing carbon/carbon crucibles based on flow field optimization, which can solve the problems of airflow blocking, crucible cracks, no longer uniform precursors, etc., to ensure uniformity, reduce cycle and cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The basic steps of the first stage:

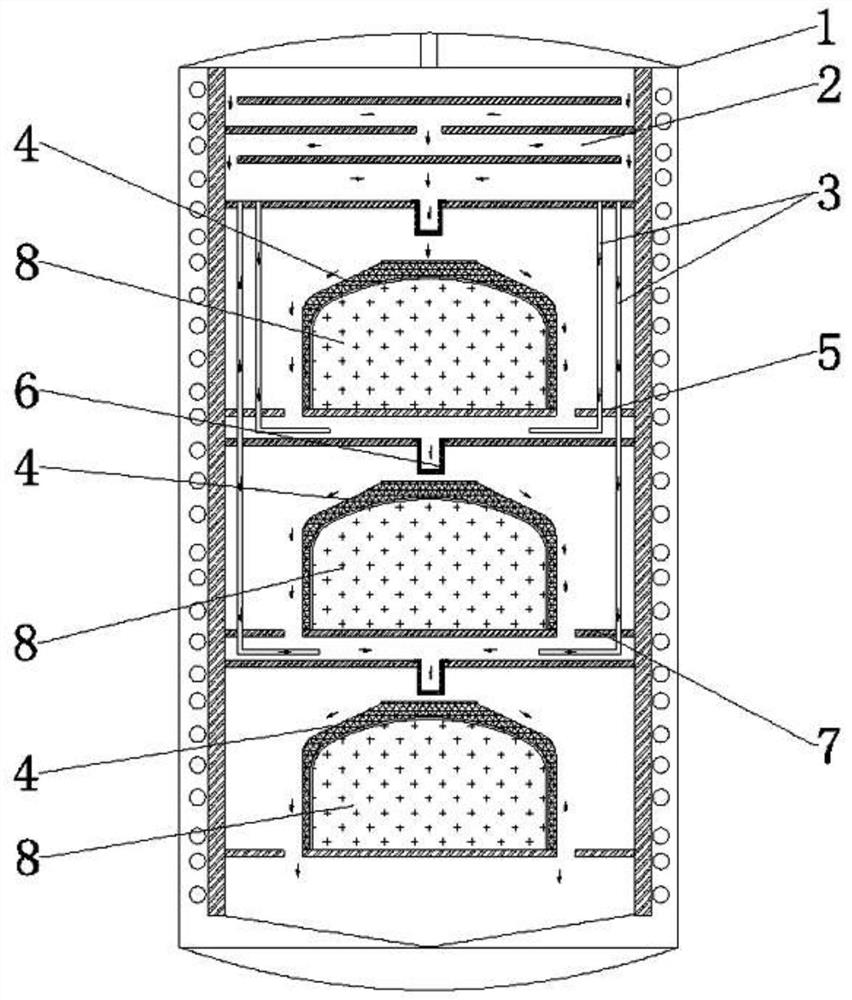

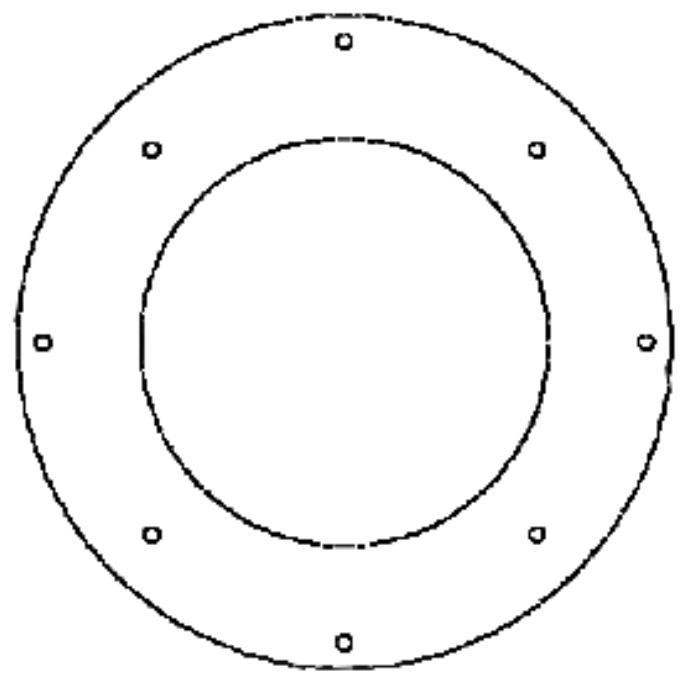

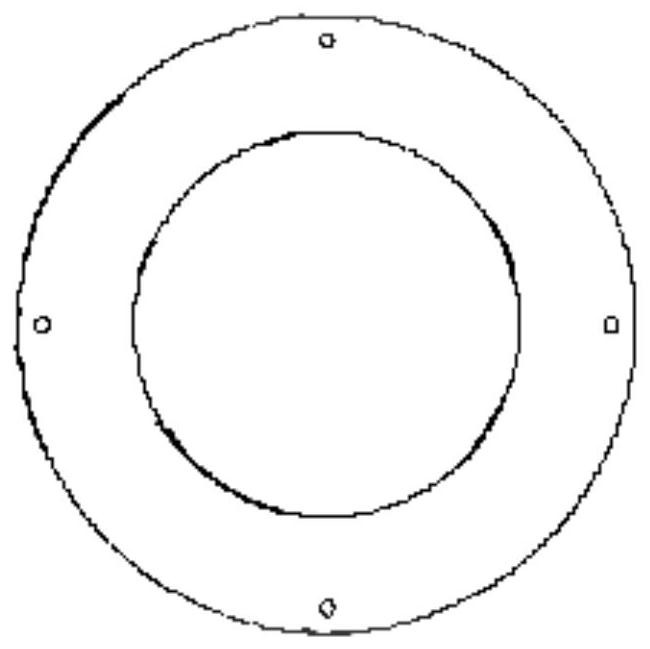

[0039] 1) Furnace loading, the carbon fiber crucible prefabricated body 4 according to the following figure 1 The shown is loaded in the high-temperature vapor deposition furnace 1, and 2 in the figure is the preheating zone, and three preforms can be placed in the constant temperature zone, and the number of preforms can be appropriately adjusted according to the size of the constant temperature zone. The support plates are separated by graphite pillars (graphite pillars are not shown in the figure). From top to bottom, the gas supply pipeline 3 appears from the second crucible preform, and the number of gas supply in each layer is 4. The top view of the graphite support plates 5 and 7 is as follows diagram 2-1 with Figure 2-2 As shown, the air supply pipeline 3 is made of quartz material. The inside of the crucible prefabricated body 4 is filled with a graphite or quartz lining 8, and the outer surface of the inner lining 8 i...

Embodiment 2

[0055] The basic steps of the first stage:

[0056] 1) Furnace loading, the carbon fiber crucible prefabricated body 4 according to the following figure 1 Filling is carried out as shown, three prefabricated bodies can be placed in the constant temperature zone, and the number of prefabricated bodies can be adjusted appropriately according to the size of the constant temperature zone. The support plates are separated by graphite pillars (graphite pillars are not shown in the figure). From top to bottom, the gas supply pipeline 3 appears from the second crucible preform, the number of gas supply in each layer is 4, and the gas supply pipeline 3 is made of quartz material. The inside of the crucible prefabricated body 4 is filled with a graphite or quartz lining 8, and the outer surface of the inner lining 8 is close to the inner surface of the crucible prefabricated body 4;

[0057] 2) Check the airtightness of the high-temperature vapor deposition furnace by vacuuming, start...

Embodiment 3

[0072] The basic steps of the first stage:

[0073] 1) Furnace loading, the carbon fiber crucible prefabricated body 4 according to the following figure 1 Filling is carried out as shown, three prefabricated bodies can be placed in the constant temperature zone, and the number of prefabricated bodies can be adjusted appropriately according to the size of the constant temperature zone. The support plates are separated by graphite pillars (graphite pillars are not shown in the figure). From top to bottom, the gas supply pipeline 3 appears from the second crucible preform, the number of gas supply in each layer is 4, and the gas supply pipeline 3 is made of quartz material. The inside of the crucible prefabricated body 4 is filled with a graphite or quartz lining 8, and the outer surface of the inner lining 8 is close to the inner surface of the crucible prefabricated body 4;

[0074] 2) Check the airtightness of the high-temperature vapor deposition furnace by vacuuming, start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com