Method and apparatus for estimating clutch friction coefficient

A clutch, clutch pressure technology, applied in clutches, mechanical equipment, components with teeth, etc., can solve problems such as inaccuracy, affecting transmission capacity estimation, engine error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

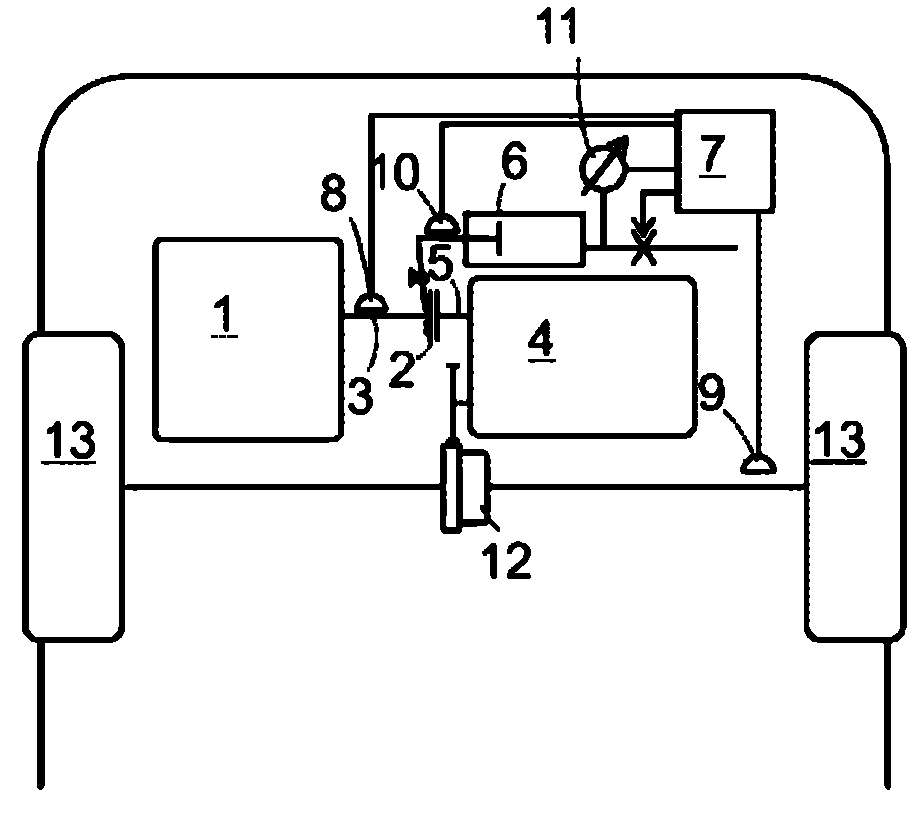

[0019] figure 1 is a schematic top view of the front part of a motor vehicle comprising a combustion engine 1, a clutch 2 for connecting the output shaft 3 of the combustion engine to the input shaft 5 of the transmission 4, a clutch 2 for controlling the opening and closing of the An actuator 6 (such as a hydraulic cylinder), an electronic transmission controller 7 for controlling the clutch 2 via the actuator 6 and the shift forks (not shown) of the transmission 4 via other actuators (not shown) .

[0020] The controller 7 has connected to it a rotational speed sensor 8 for monitoring the rotational speed of the output shaft 3, a speedometer 9, and an actuator controller sensor such as a Hall sensor 10 for monitoring the piston of the actuator 6. The displacement, or the pressure sensor 11, is used to monitor the hydraulic pressure in the cylinder of the actuator 6).

[0021] Reference numeral 12 denotes a differential driven by an output pinion of the transmission 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com