Last with grip device for shoemaking

A clamping device and shoe last technology, which is applied in the field of shoe lasts, can solve problems such as poor positioning of shoe lasts, difficult precise positioning, manufacturing errors, etc., and achieve high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

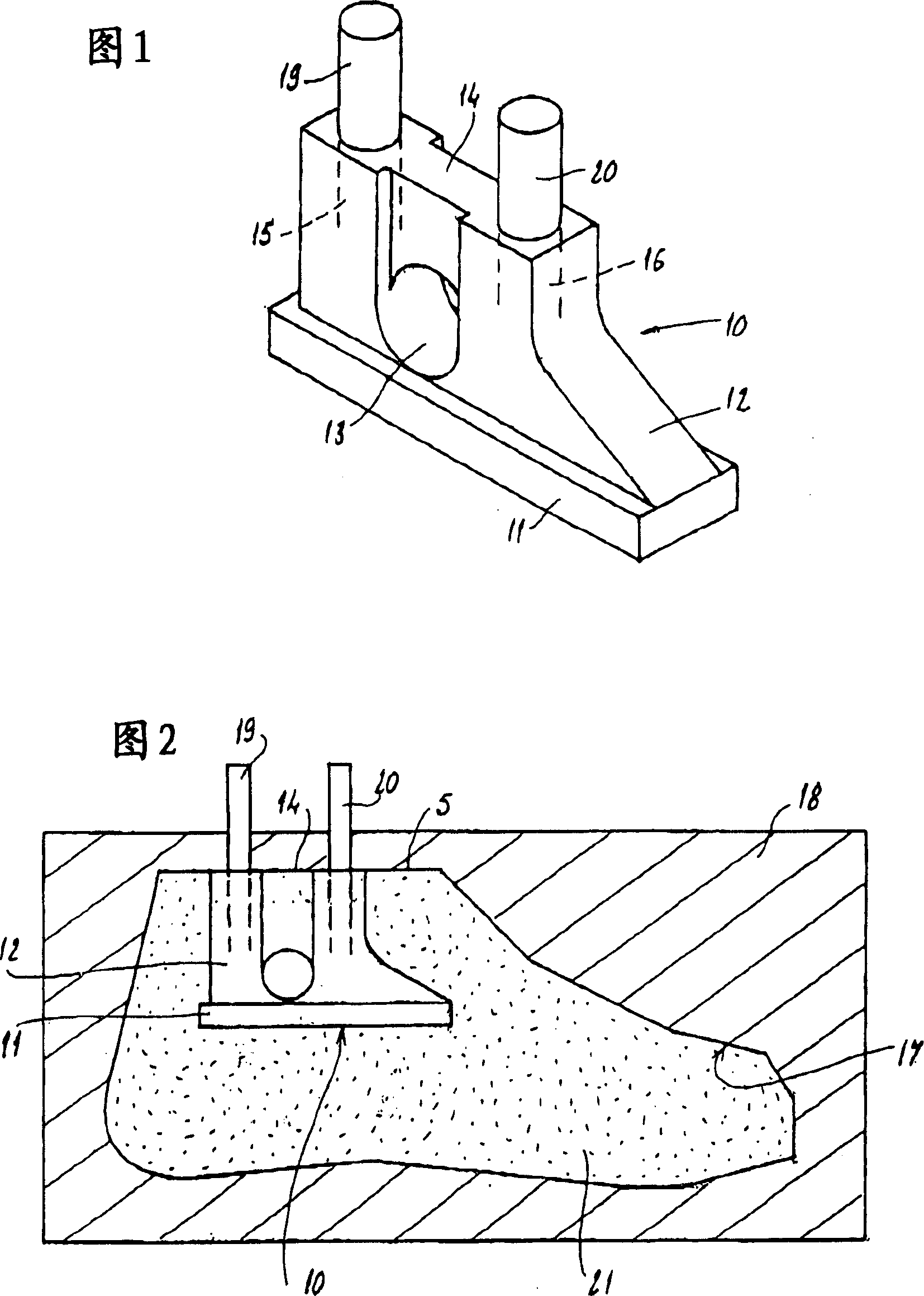

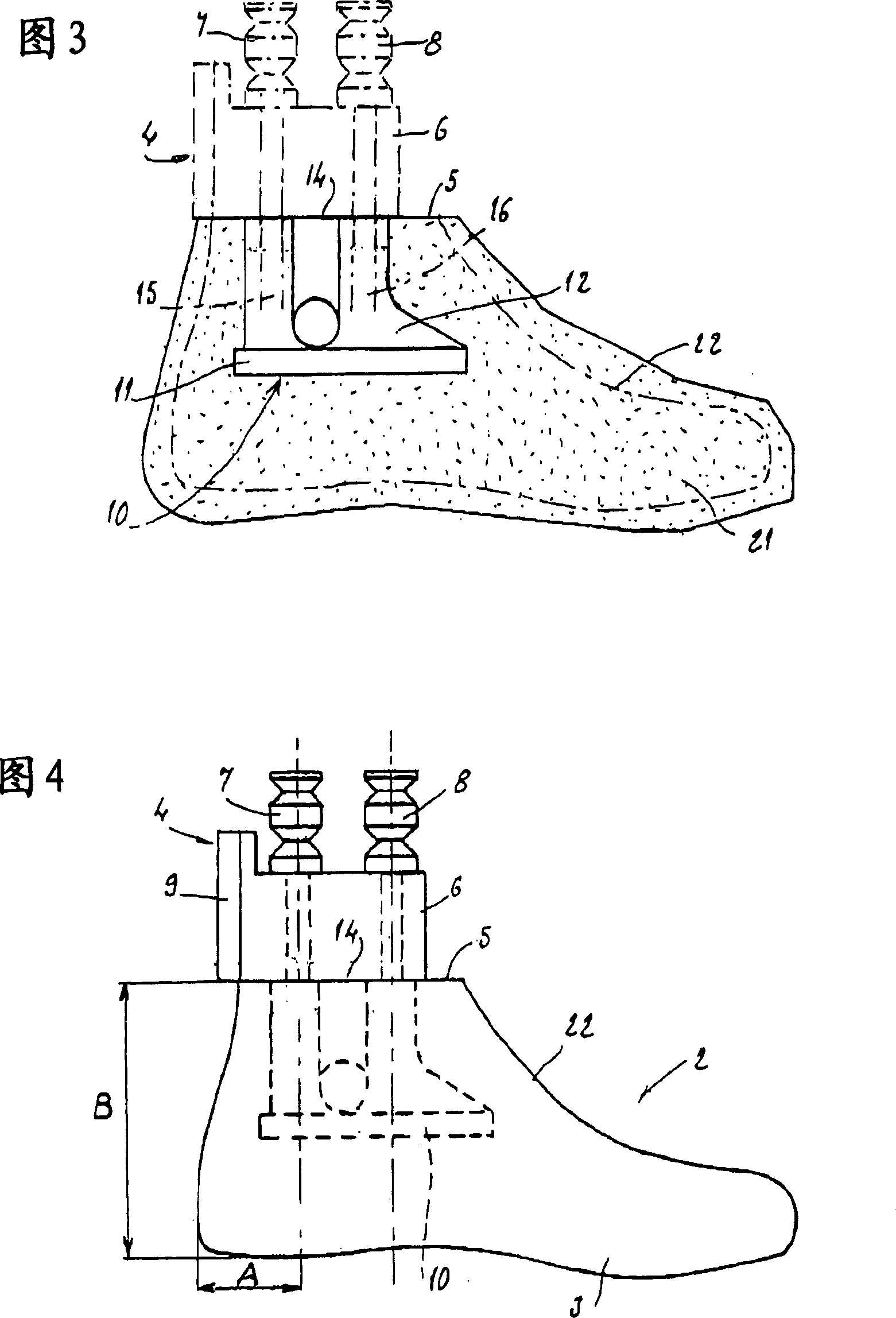

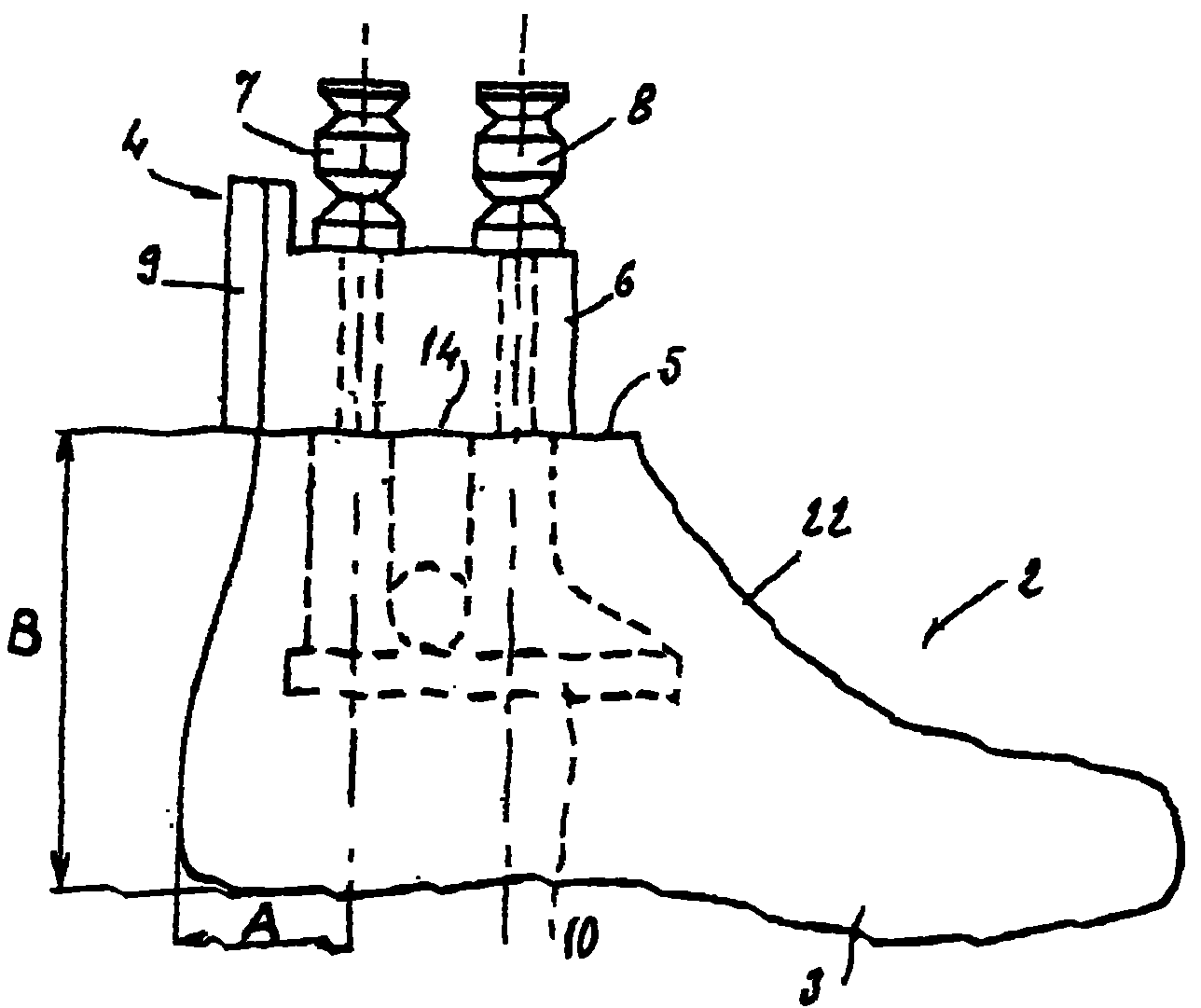

[0020] Referring first to Fig. 4, a last for the manufacture of a shoe (indicated generally by the reference numeral 2) comprises a body 3 on the one hand and a gripping device or "clip" 4 on the other hand. The body 3 of the last made of resin reproduces the characteristics of the foot, thus serving as a model during the manufacture of the elements of the shoe. The clip 4 protrudes upwards from the upper surface 5 of the main body 3 of the shoe last 2 for controlling and fixing the shoe last 2 . In the example shown, the clip 4 comprises, on the one hand, a plate or elongated block 6 (on the upper surface 5 of the body 3 of the last 2) and, on the other hand, two elongated tubular elements 7 and 8, The two tubular elements are parallel to each other and perpendicular to the upper surface 5 of the main body 3, and the upper parts of the two tubular elements 7 and 8 are hourglass-shaped. The elongated block 6 is followed by a coding unit 9 (this clamping structure itself is kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com