Wood-plastic inward opening sash sectional material forming die

A technology for forming molds and fan profiles, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of complex design, inconvenient and stable installation, and unsightly profiles, so as to achieve good use effect, good practical use and promotion Simple and practical effect of value and structure improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

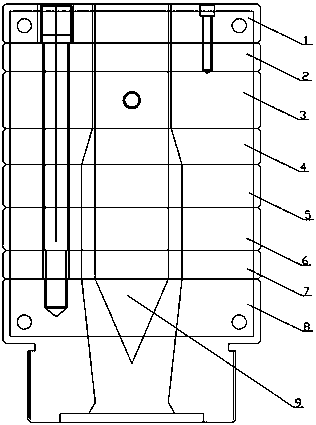

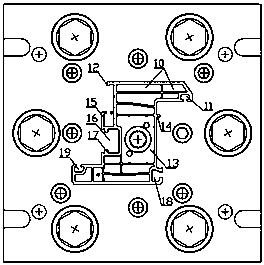

[0010] see Figure 1-2 , the present invention is a wood-plastic inner-opening profile forming mold, which is sequentially connected with a die a1, a die b2, a die c3, a manifold 4, a support plate a5, a support plate b6, and a transition plate from top to bottom through screws 7. The mold body 8 and mandrel 9, the mold cavity formed by die a, die b, and die c has a "Z"-shaped frame, and the upper end of the "Z"-shaped frame is separated by several frames 10, which are located in a The lower corner of the side frame is provided with a C-shaped card slot A11, and the outer wall of the other side frame is provided with a hook A12. The middle part of the "Z"-shaped frame is a large rectangular frame 13, and the large rectangular frame is close to the C-shaped card slot. There is a hook B14 on one frame side of A, and a "C"-shaped card slot B15 at the upper end of the other side frame, and an inward groove 16 at the lower end of the "C"-shaped card slot B, and the upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com