Locking mechanism and safety belt retractor

A locking mechanism and locking block technology, which are applied in the directions of seat belts, belt tensioners, transportation and packaging in the car, can solve the problems of high vibration and noise, reduce vibration and noise, and realize one-way rotation locking. Function and stability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

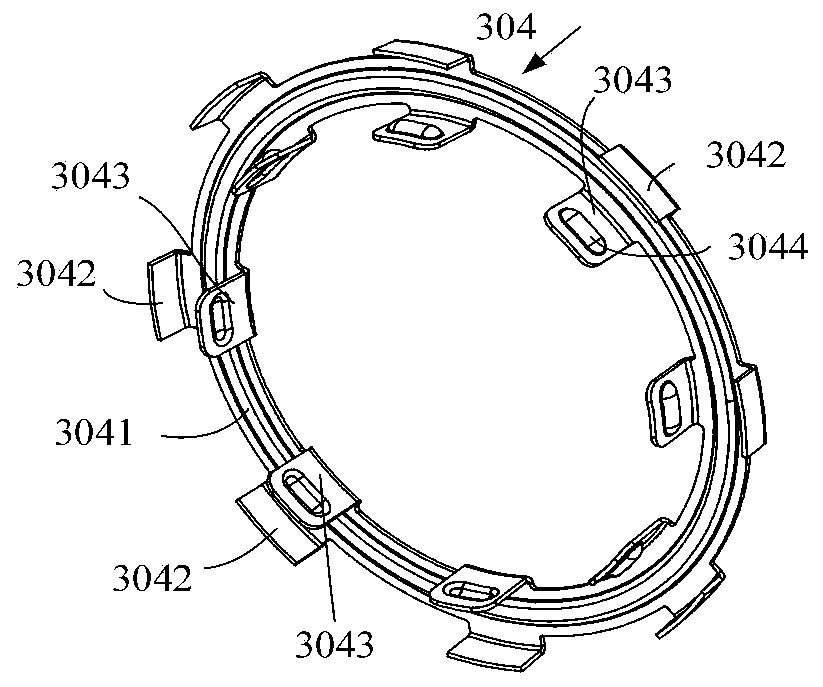

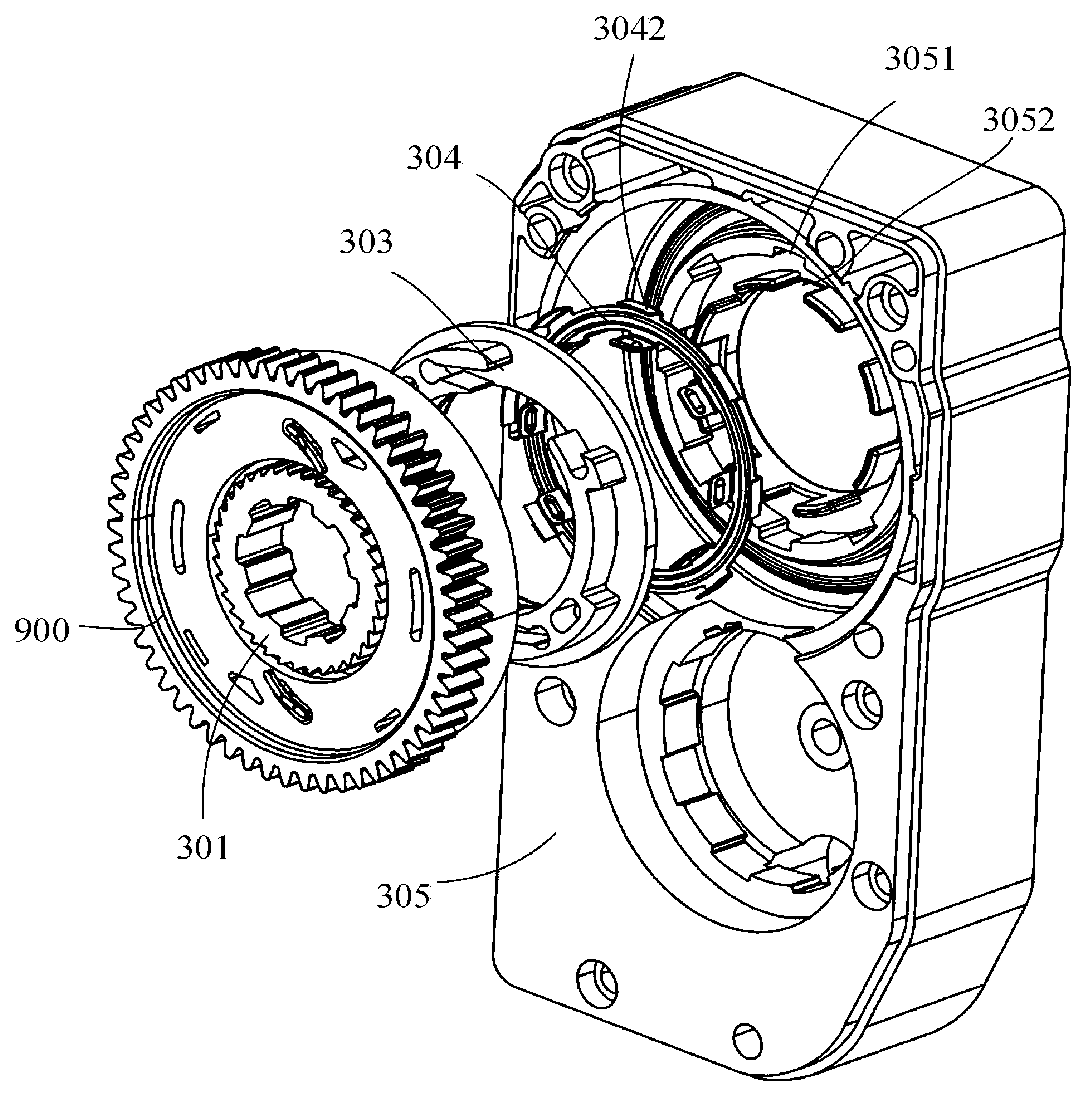

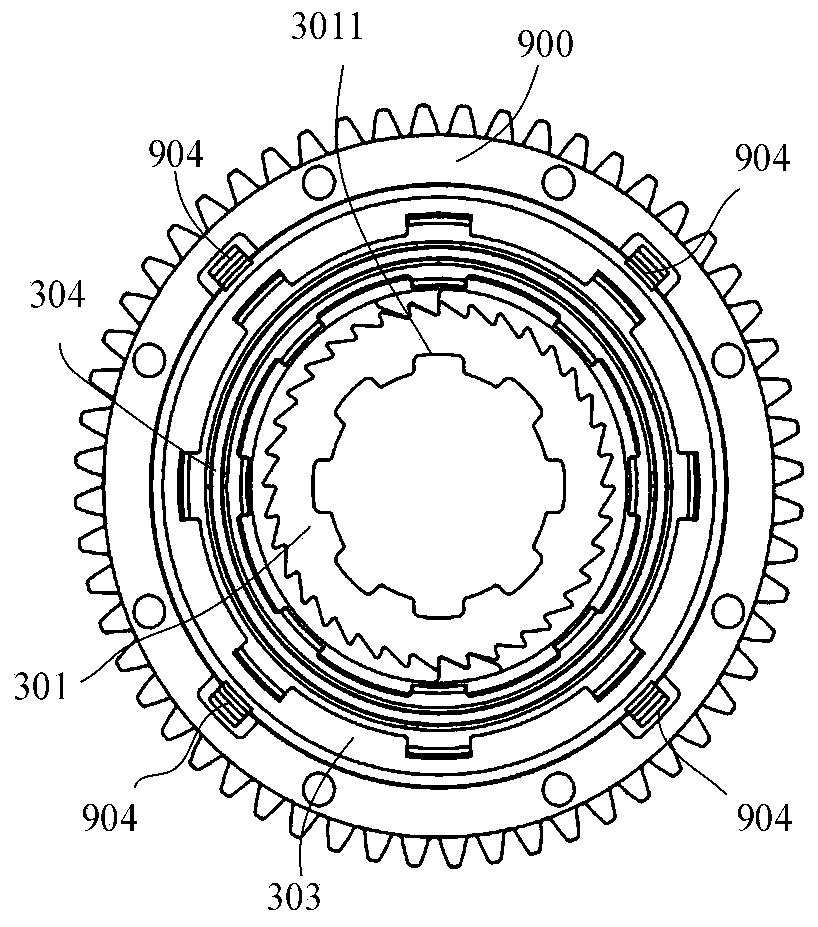

[0053] According to an embodiment of the present invention, a motor-driven safety belt retractor is provided, such as Figure 1 to Figure 34 As shown, it includes an electric motor 600, a reduction mechanism assembly 200, a main gear 900, a clutch assembly 300 and a spindle assembly 500, wherein the output end of the electric motor 600 is connected to the reduction mechanism assembly 200, and the output end of the reduction mechanism assembly 200 is connected to the main The gear 900 is meshed and connected, the main gear 900 is connected with the mandrel assembly 500 through the clutch assembly 300, and the mandrel assembly 500 is driven to rotate by the motor 600; wherein, the output end of the motor 600 is provided with a driving gear 601, and the reduction mechanism assembly 200 adopts a planetary The frame gear structure or the eccentric swing gear structure, the motor 600 is decelerated by the reduction mechanism assembly 200, and the motion is transmitted to the main gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com