A device and method for on-line preparation of a weak grating array with continuous wavelength variation

A wavelength-changing, weak grating technology, applied in measuring devices, optical waveguide light guides, optics, etc., can solve the problems of small wavelength types and difficulty in completely eliminating grating crosstalk, so as to reduce shadow effects, improve sensing distance and multiplexing capacity , Improve the effect of multiplexing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

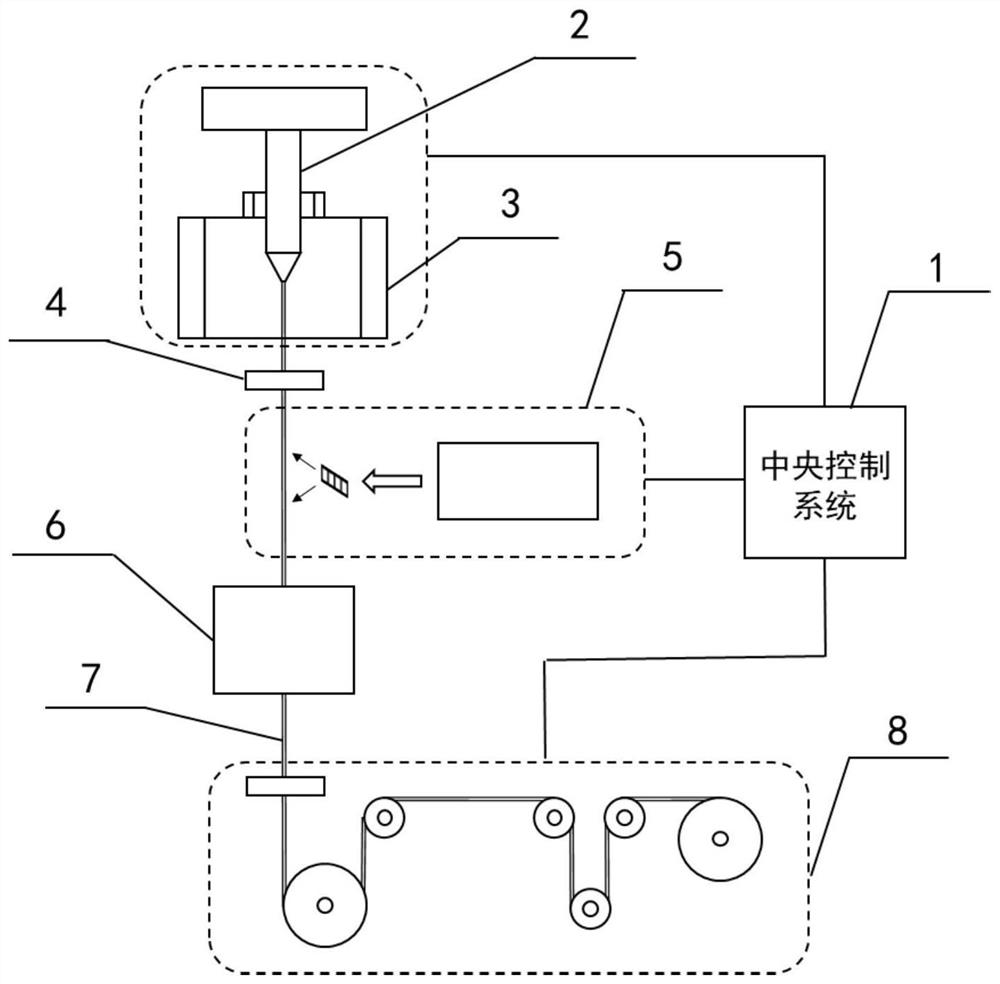

[0031] like figure 1 , figure 2 and image 3 The shown on-line grating array device with continuous wavelength change includes a central control system 1, a preform feeding device 2, a high-temperature heating furnace 5, an optical fiber diameter detection device 4, an online writing grating platform 3, and a double-coating curing device 6 and the optical fiber pulling device 8, the preform feeding device 2 sends the raw material preform to the high temperature heating furnace 3 at a certain speed, the output end of the drawn bare fiber corresponds to the bare fiber input end of the optical fiber diameter detection device 4, and the online The writing grating platform 5 is located between the output end of the optical fiber diameter detection device 4 and the input end of the double-coating curing device 6, and the output end of the double-coating curing device 6 is connected to the optical fiber drawing and forming device 8, and the grating optical fiber 7 is stored in a re...

Embodiment 2

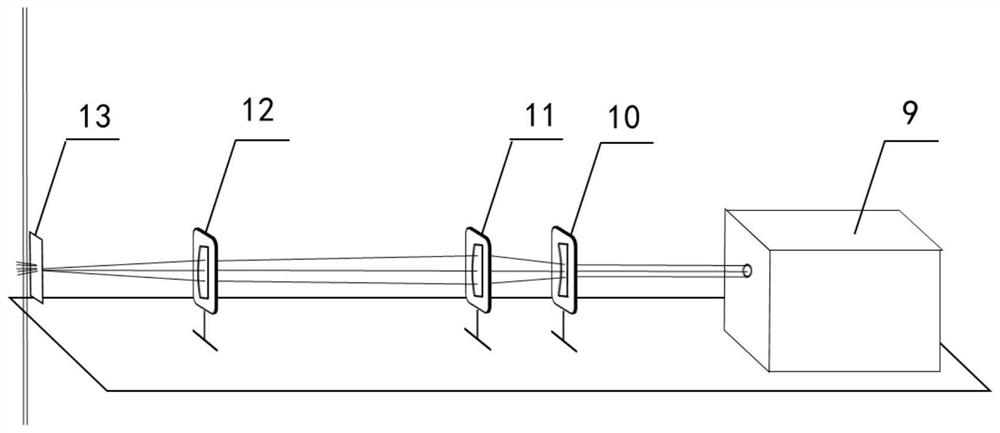

[0035] On-line fabrication of grating array devices with continuous wavelength variation, including fiber drawing tower systems and on-line writing grating systems. The optical fiber drawing tower system includes a preform feeding device, a high-temperature heating furnace, a double coating and curing device, a two-stage optical fiber diameter measuring instrument, an optical fiber drawing device and a central control system for controlling each part of the unit. Through the coordinated control of various components by the central control system, the process of drawing the optical fiber preform into bare fiber and then to the finished optical fiber is realized, and finally the optical fiber is coiled through the take-up device. During this process, the drawing speed, the length and diameter of the fiber drawn can be fed back and controlled by the control system to achieve uniform drawing of the fiber. The line writing grating system includes a 193nm excimer laser, a set of opt...

Embodiment 3

[0037] Provided in this embodiment is a method for online preparation of a grating array with continuous wavelength variation, which includes the following steps:

[0038] Step 1, the central control system 1 controls the preform feeding device 2 and the high-temperature heating furnace 3 to draw the raw material preform into a bare fiber, and the diameter of the bare fiber reaches a stable state through the real-time feedback of the optical fiber diameter detection device 4. At this time, the bare fiber The drawing speed is also at a relatively stable value.

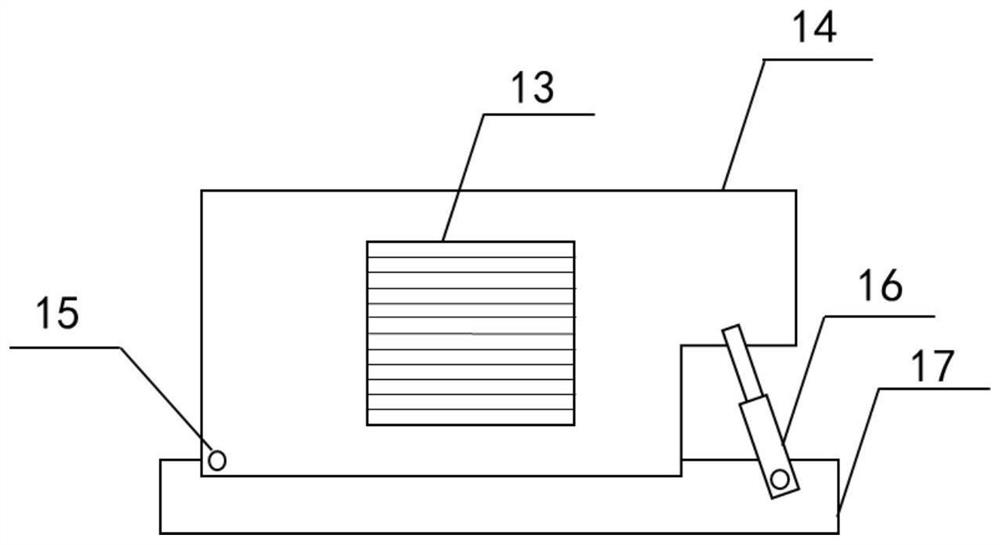

[0039] Step 2, the central control system 1 presets the laser pulse cycle and intensity of the laser writing device 9, so that the online grating writing platform starts to work and prepares to write gratings; at the same time, the central control system 1 controls the controllable telescopic slider 16 to expand and contract, and its initial The length is the shortest state and just makes the perpendicular line of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com