Motion mechanism with self-powered mechanism and communication network

A motion mechanism, self-powered technology, used in electrical components, circuit devices, transmission systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

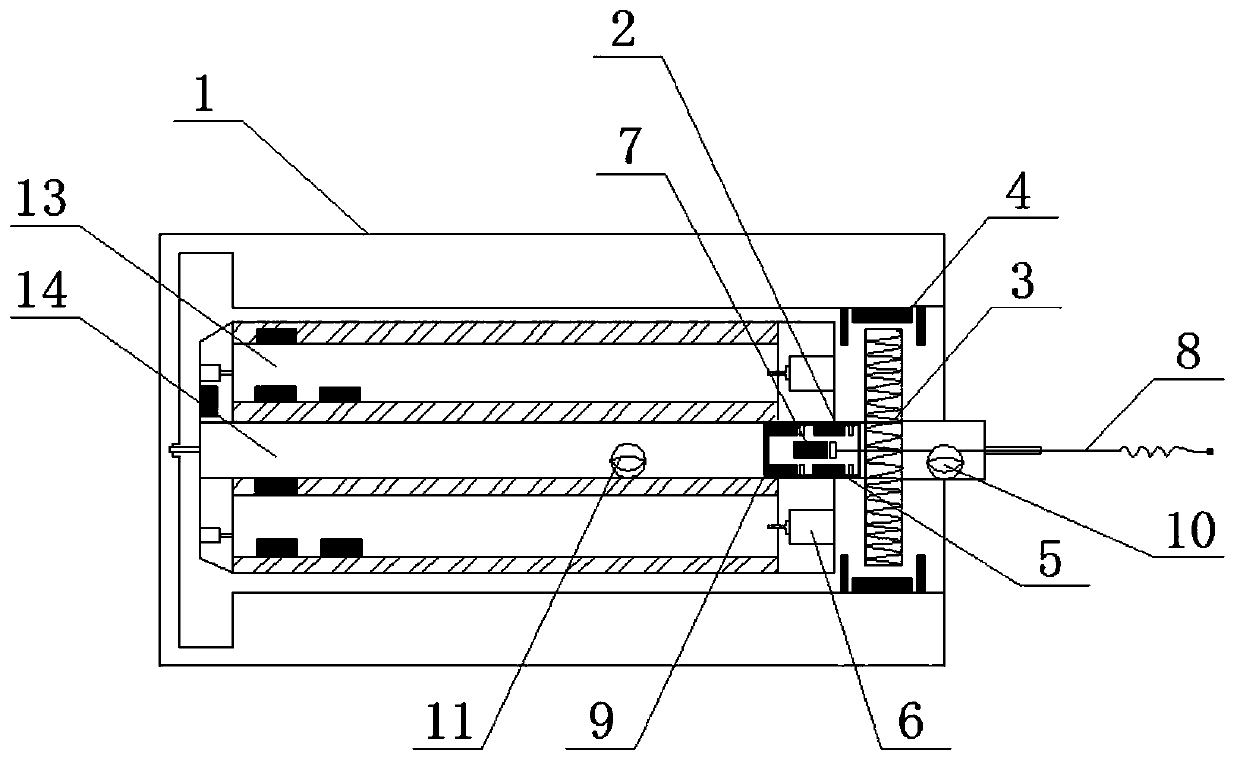

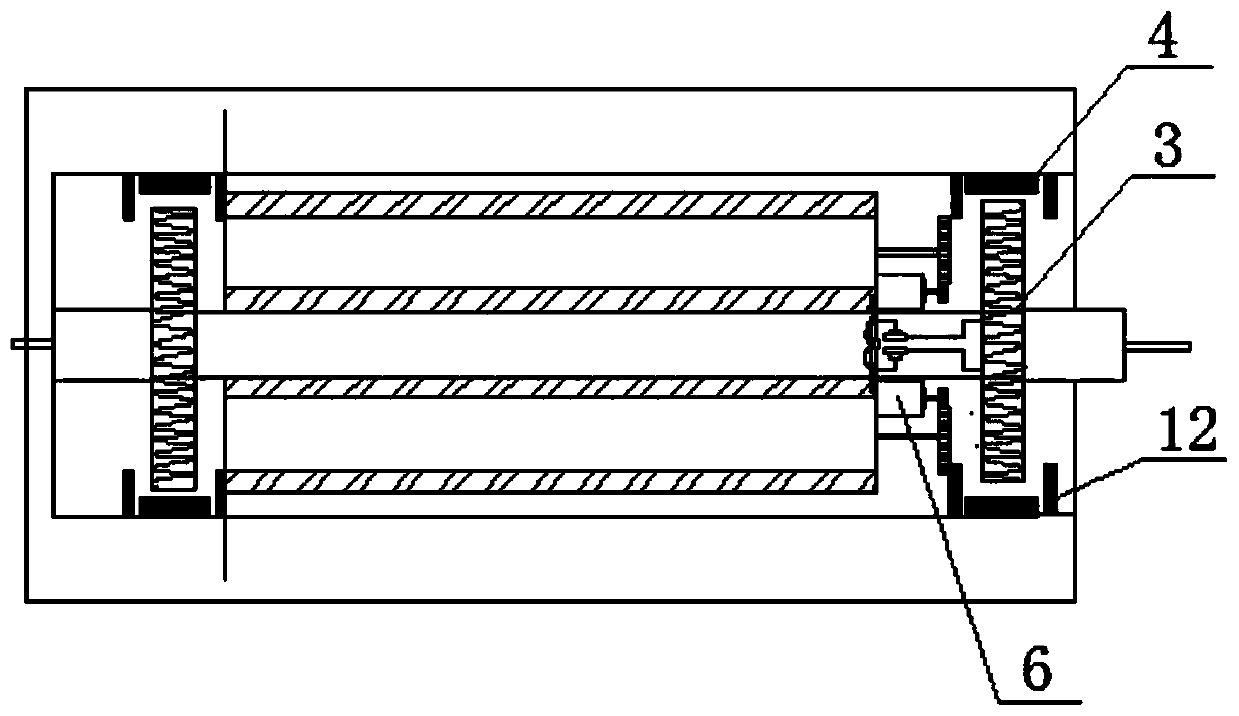

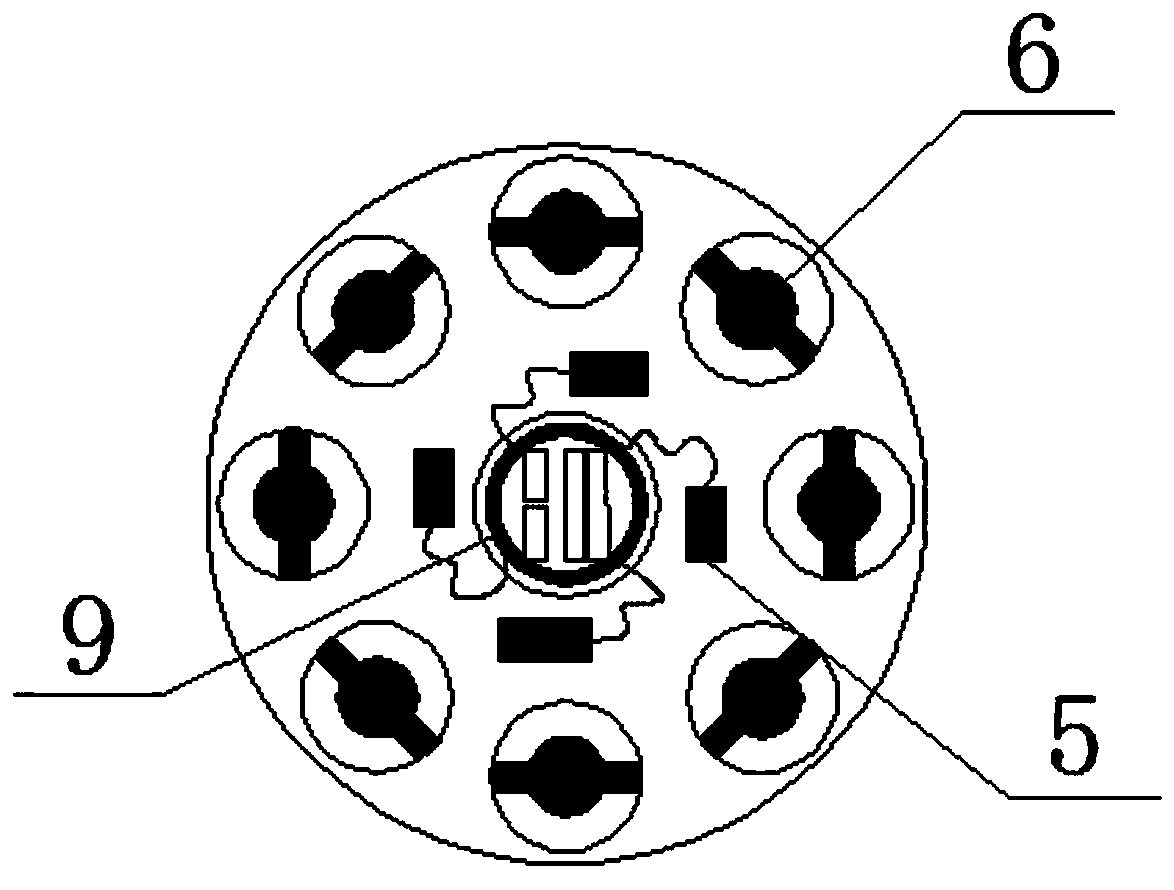

[0025] see Figure 1-5 Describe a preferred embodiment of the present invention, a motion mechanism with a self-power supply mechanism, which includes a first body 1, a second body 14, a self-power supply mechanism, a first power conversion mechanism 2 and an electric load: wherein, the first The two bodies 14 are arranged inside or outside the first body 1, and when the motion mechanism works, the two bodies move relative to each other. In this embodiment, the second body 14 is located inside the first body 1, and the two are arranged axially. When the movement mechanism is working, the second body 14 rotates around its own axis, and the self-power supply mechanism is connected with the first power conversion mechanism 2. The number of electric loads is one or more, the first power conversion mechanism 2 is connected to one or more electric loads respectively, the self-power supply mechanism includes a generating winding 3 and a magnetic field generating mechanism 4, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com