Unpowered forward cap and reverse cap automatic removal device

A rejection device, automatic technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of identification errors, capping machines suspend production, unstable operation methods, etc., to avoid identification errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

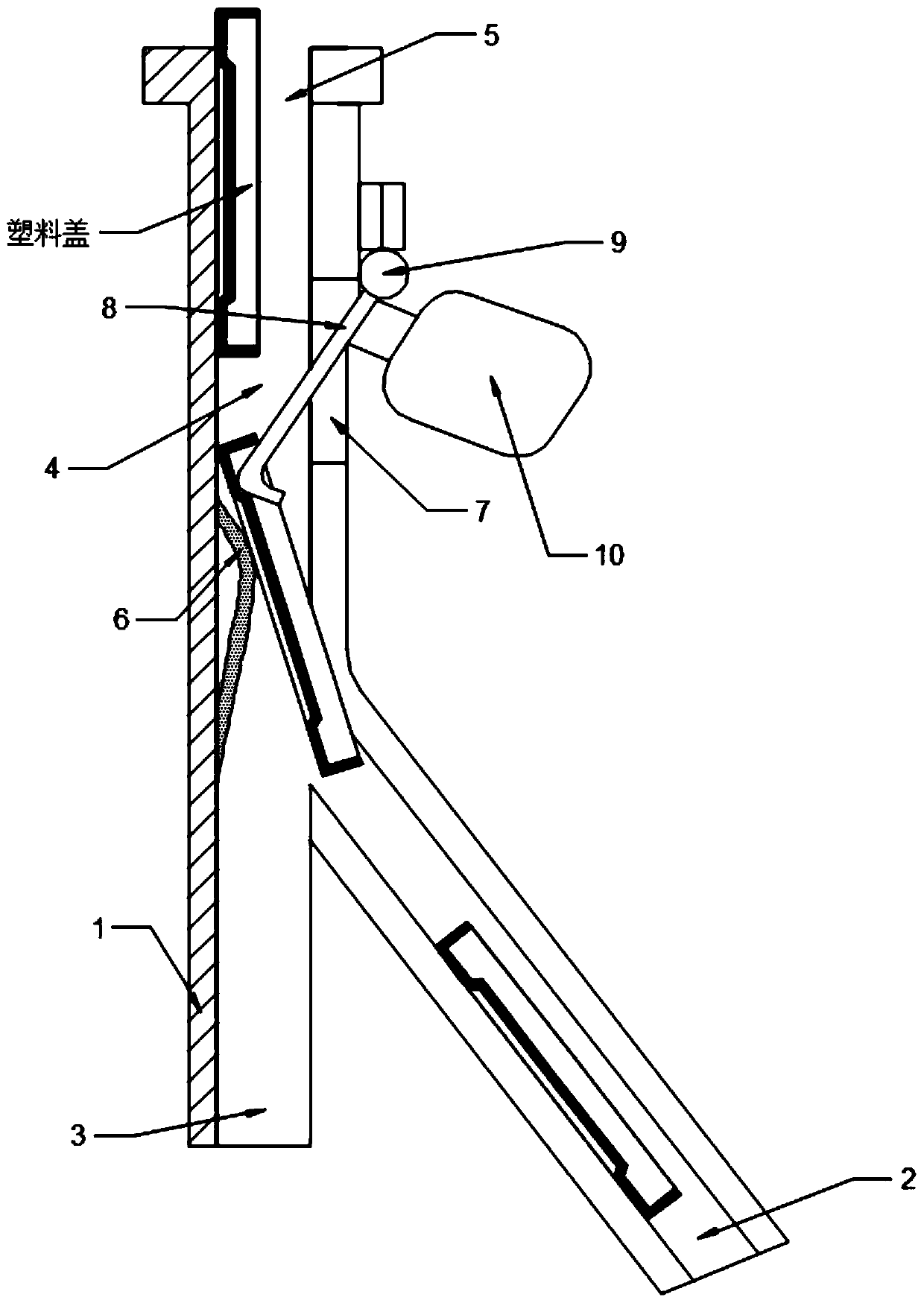

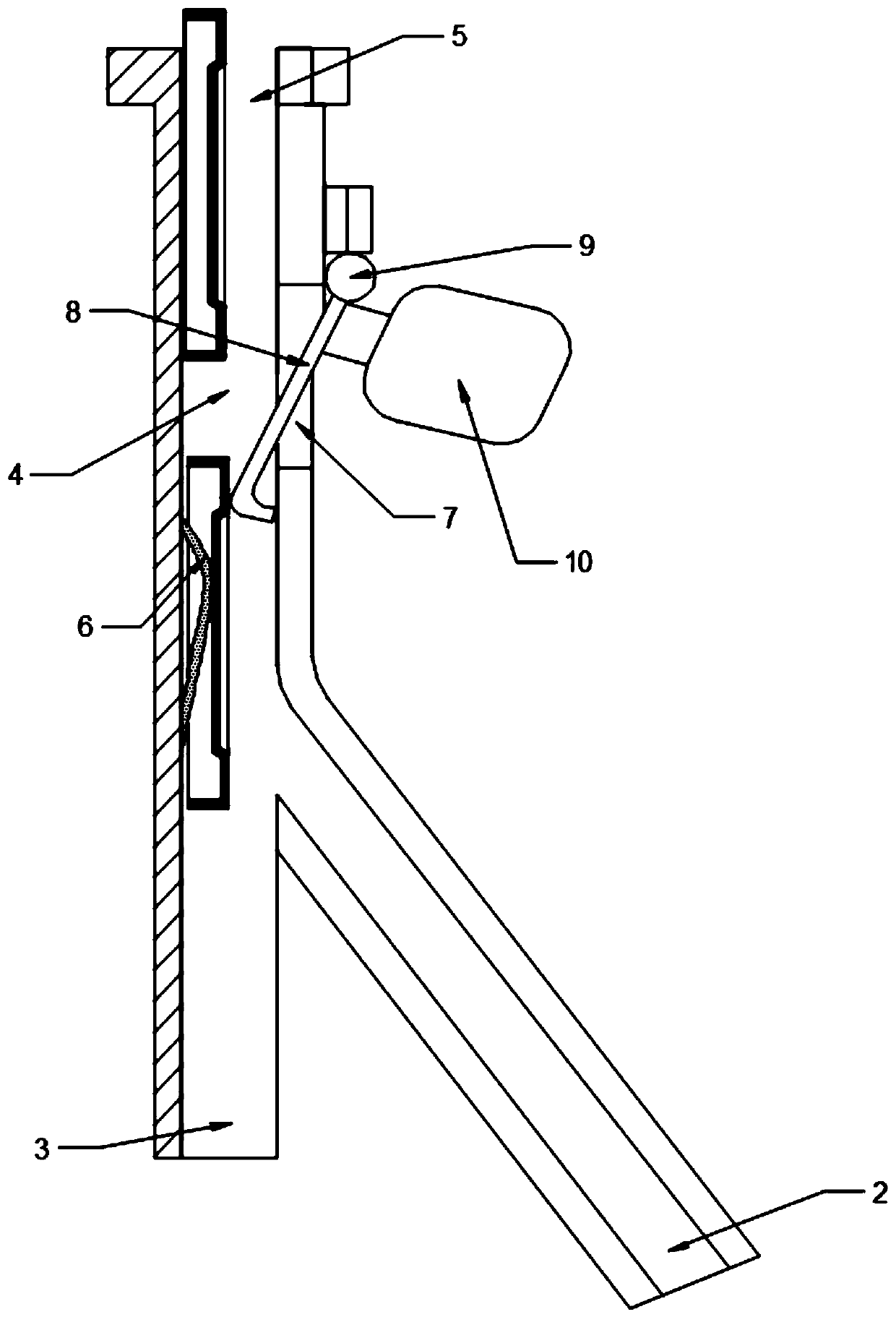

[0021] see Figure 1 to Figure 2 , the present invention provides an automatic removal device for front and back covers without power, comprising a housing 1 and a sub-cover passage, the sub-cover passage is located at the bottom of the housing 1, and the sub-cover passage is connected to the housing 1 The interior of the housing 1 is connected, the center of the housing 1 is provided with a guide groove 4, the top of the housing 1 is provided with a cover opening 5, one side of the inner wall of the guide groove 4 is provided with an ejection plate 6, and the guide groove The inner wall of the other side of 4 is provided with a notch 7, and a pressing plate 8 is pierced in the notch 7, and an overturning assembly is provided on the outer wall of the housing 1, and the outer end of the pressing plate 8 is hinged with the overturning assembly, so The pressing plate 8 can rotate in the notch 7 under the drive of the turning assembly.

[0022] The plastic cover is sent into the ...

Embodiment 2

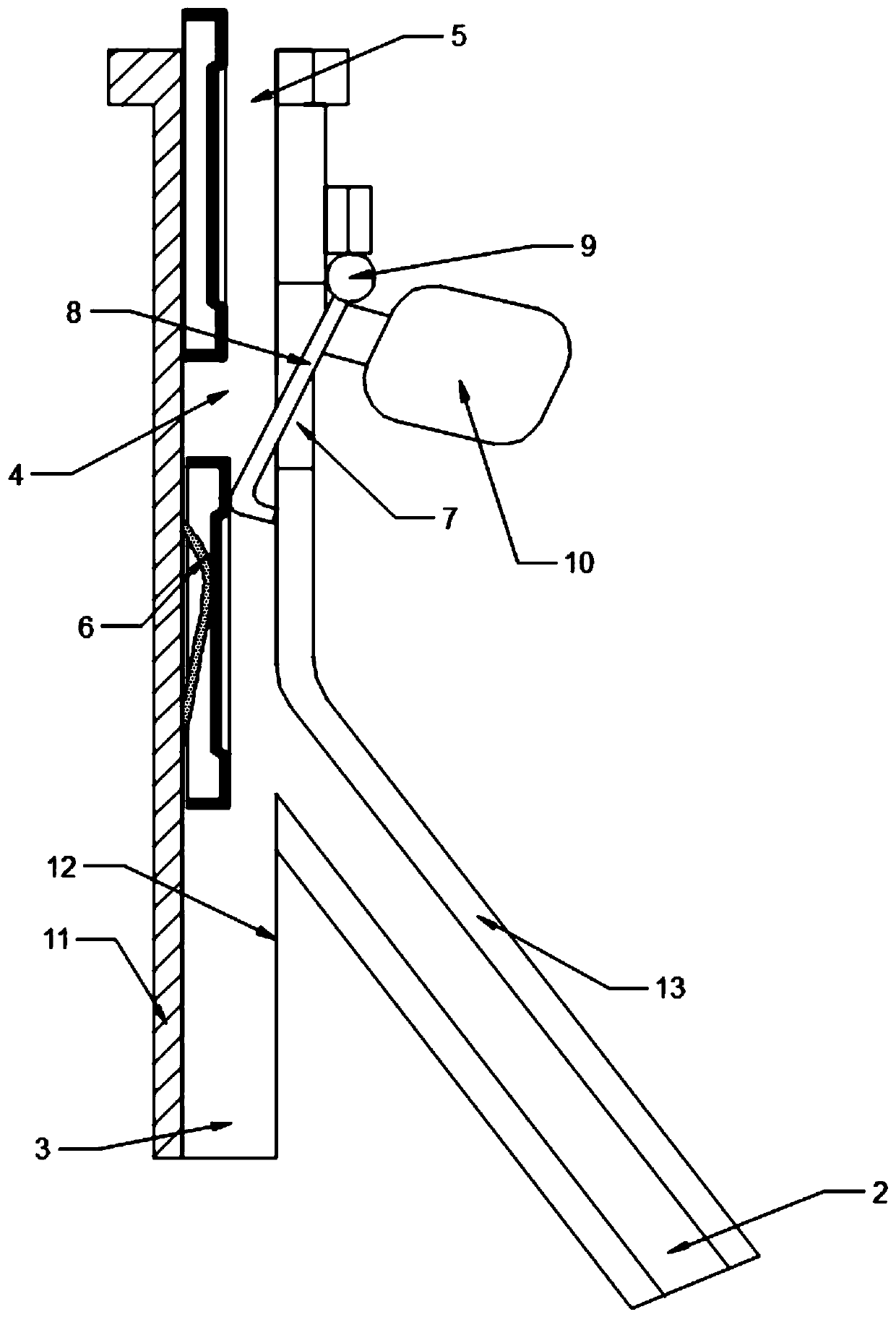

[0027] see image 3 , the present invention provides an automatic rejecting device for front and back covers without power. The housing 1 includes a bottom plate 11 and a “concave”-shaped base 12 , and the bottom plate 11 is connected to the base 12 .

[0028] The second cover outlet 3 is composed of several guide round steels 13, through which the contact area with the plastic cover is reduced, thereby reducing the frictional force and facilitating the sliding out of the plastic cover.

[0029] The bottom plate 11 and the base 12 are detachably connected by bolts, which is convenient for subsequent inspection and maintenance of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com