Self-locking type amplifying lifting mechanism

A lifting mechanism and self-locking technology, applied in the field of self-locking amplifying lifting mechanism, can solve the problems of high cost and complex hydraulic drive system, shorten the length of the tie rod, reduce the weight of the mechanism, and improve the lifting stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

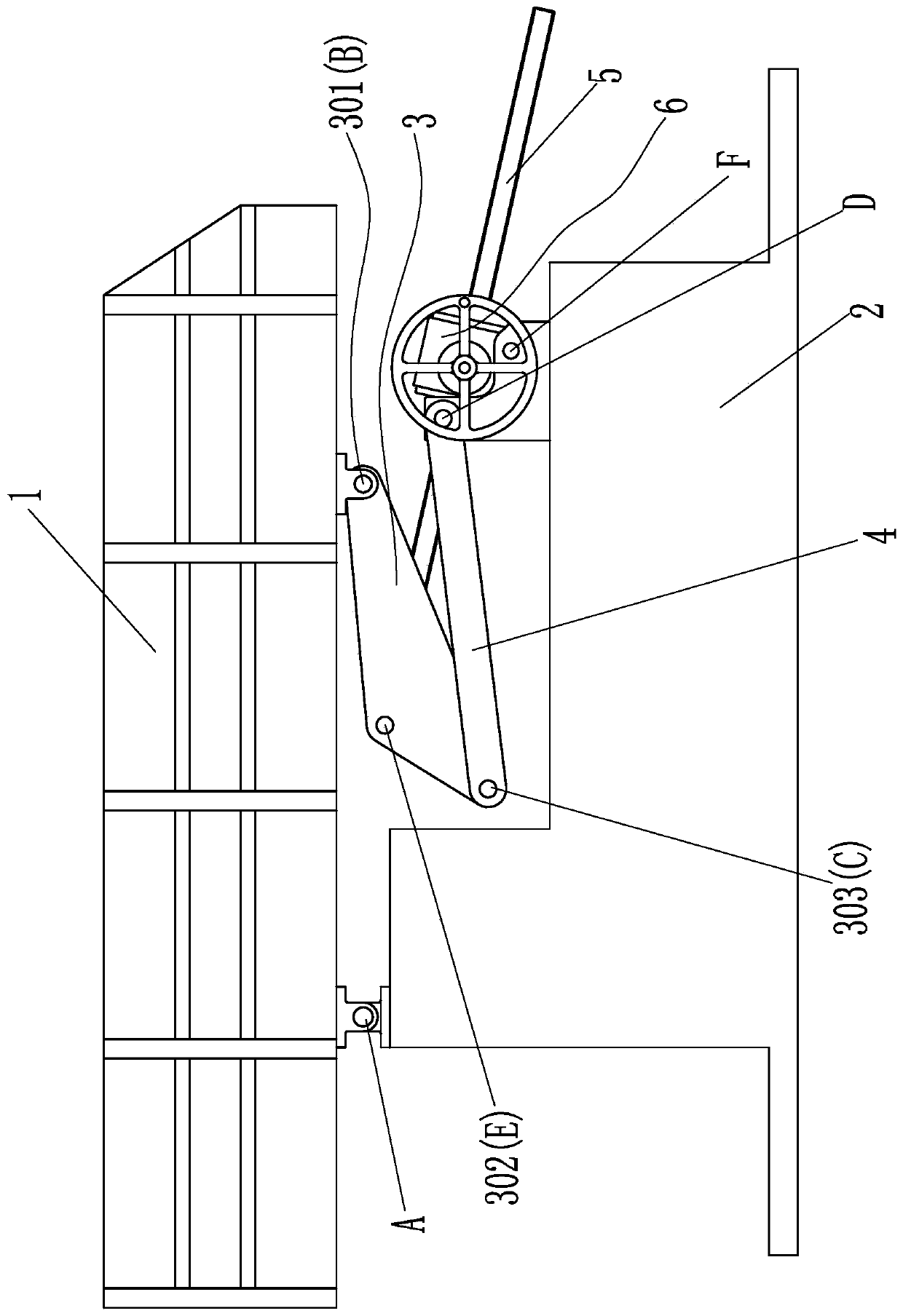

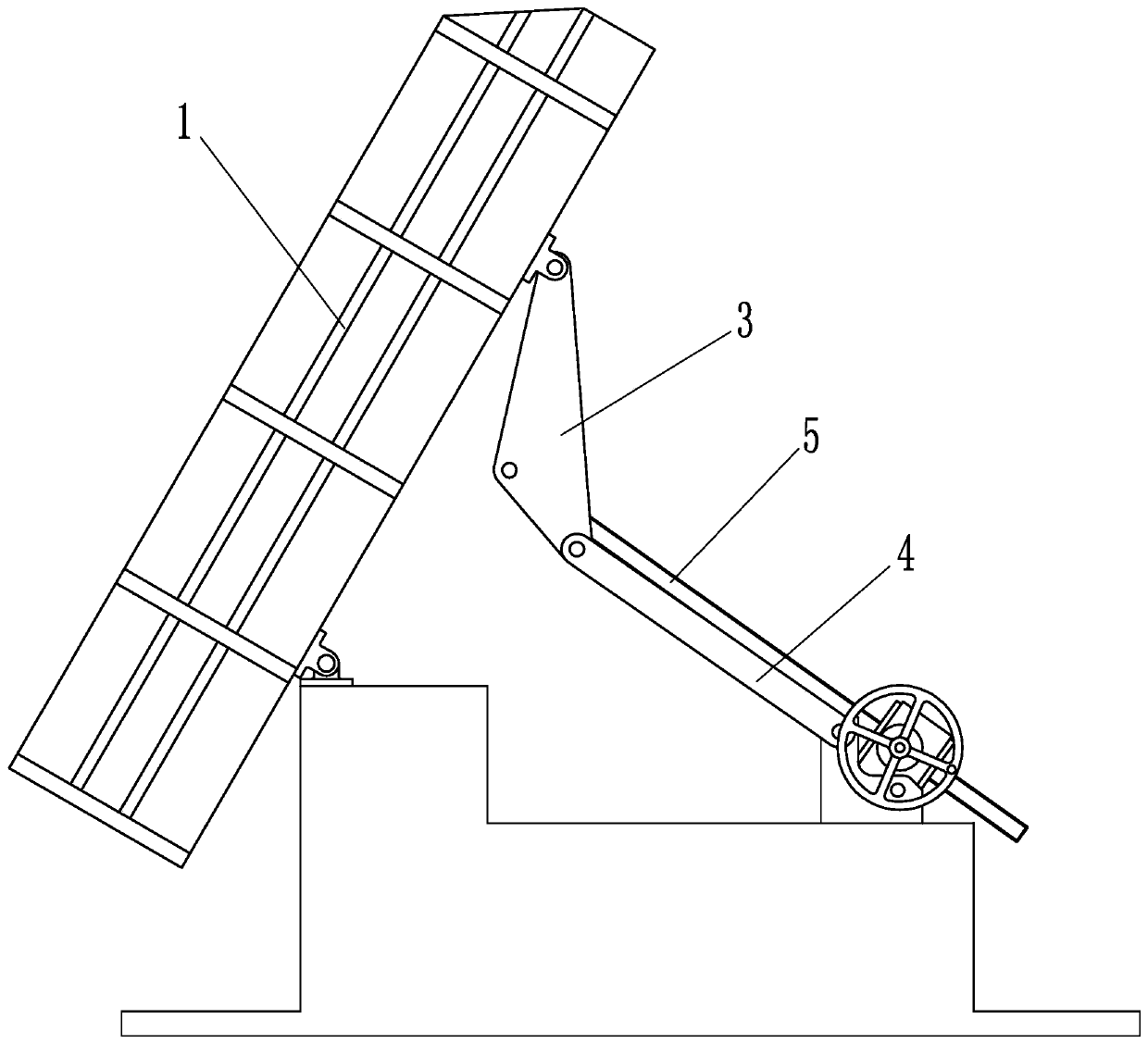

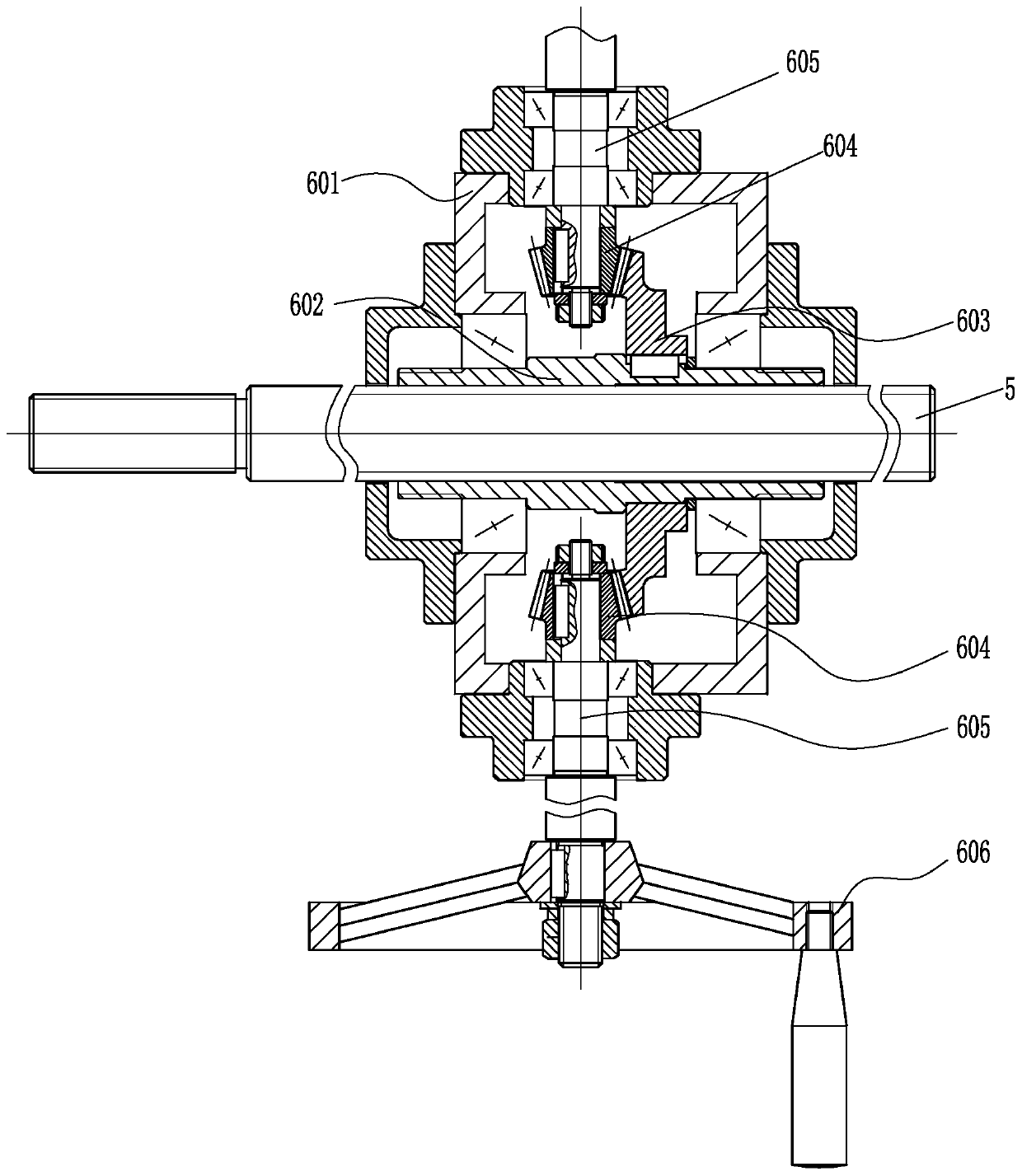

[0014] Such as Figure 1 to Figure 3 As shown, the self-locking enlarged lifting mechanism of the present invention includes a bracket 1 , a lift and a base 2 . Bracket 1 is used to lift objects. The rear end of the bottom end of bracket 1 is hinged with the rear end of base 2. The hinge is the first hinge point A. The lift is connected between the front end of base 2 and the front end of bracket 1. between. The lift comprises a reduction box 6, two triangular arms 3, two pull rods 4 and a leading screw 5. The two triangular arms 3 are relatively arranged at the bottom of the bracket 1, and three hinge points are respectively set at the three corners of each triangular arm 3, and the three hinge points are respectively hinge point I301, hinge point II302, and hinge point III303. The hinge points I301 of the two triangular arms 3 are respectively hinged with the front side of the bottom end of the bracket 1, and this hinge point is the second hinge point B. The hinge points ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com