Planar heavy-load electro-hydraulic controllable wood grasping machine

A forklift and electro-hydraulic technology, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., can solve the problem of poor stability and lack of controllable mechanism loading and unloading machinery. Problems such as overload protection and vibration-absorbing means have been solved to achieve strong engineering application prospects and development potential, improved rigidity and operational stability, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

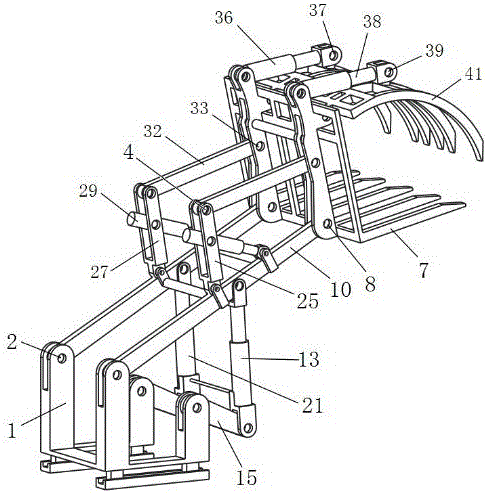

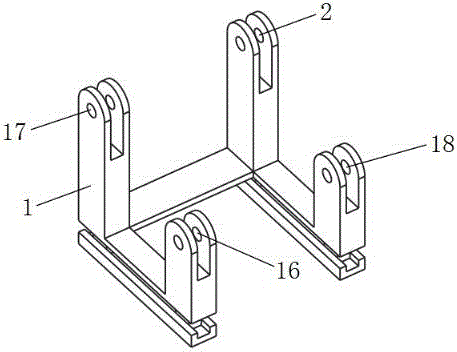

[0025] control figure 1 , a planar heavy-duty electro-hydraulic controllable forklift according to the present invention includes a boom lifting mechanism, a fork bucket control mechanism and a frame 1 .

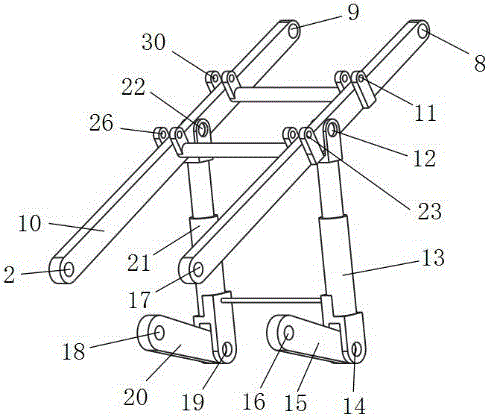

[0026] control figure 1 , figure 2 , image 3 , the boom lifting mechanism includes a first boom lifting branch chain, a second boom lifting branch chain, and a boom 10, and the first boom lifting branch chain includes a first active rod 15 and a first hydraulic cylinder 13, One end of the first active rod 15 is connected to the frame 1 through the first rotating pair 16, and the other end is connected to one end of the first hydraulic cylinder 13 through the second rotating pair 14, and the other end of the first hydraulic cylinder 13 is connected through the third rotating pair. The pair 12 is connected to the boom 10, and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com