Manifold device for fuel cell stack

A fuel cell stack and manifold technology, which is applied to fuel cells, fuel cell additives, circuits, etc., can solve the problems of inconvenient mass production, low performance of battery cells, and insufficient effect to meet the uniformity of gas distribution. The effect of increasing volume power density and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

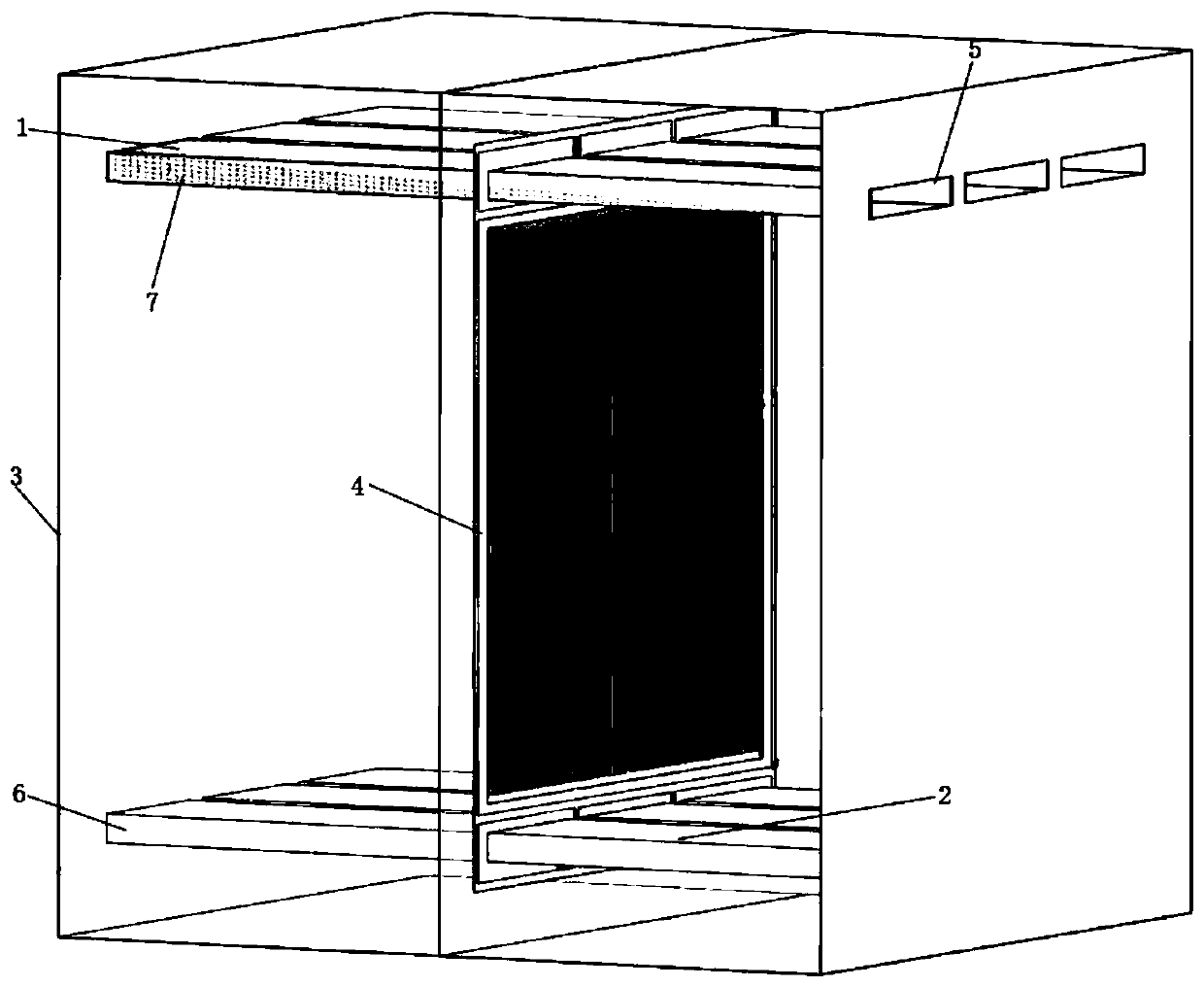

Embodiment 1

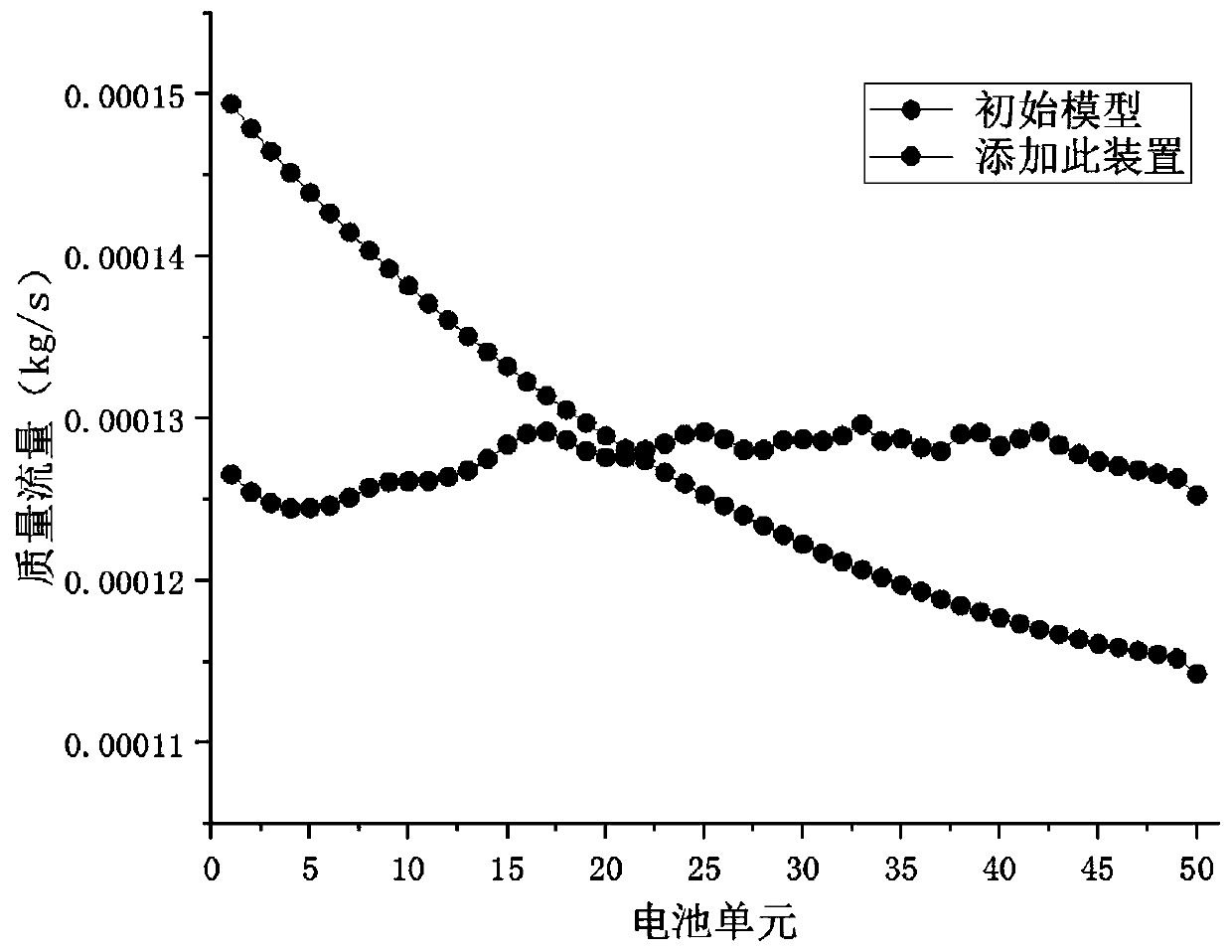

[0022] The blocking block is made of porous material and fills the entire inner cavity of the intake manifold, and the porosity of the blocking block decreases along the air intake direction.

[0023] The fuel gas enters the stack from the inlet of the intake manifold. When the gas flows through the block, the porosity is adjusted to make the gas flow through the battery cells near the inlet different from the gas flow of the battery cells far from the inlet. The change of the gas distribution improves the gas distribution performance of the rectangular duct inlet pipe with poor uniformity of gas flow distribution, improves the flow uniformity, and improves the performance and service life of the overall battery stack.

Embodiment 2

[0025] The blocking block is made of porous material, the thickness of the blocking block increases along the air intake direction, and the porosity is uniform.

[0026] Using 3D printing technology, it is possible to realize the trapezoidal or triangular structure of the porous material block forming with gradual thickness, increase the thickness of the porous material at the position where the air volume of the intake manifold is large, and reduce the porous material at the position where the air volume of the intake manifold is small The thickness of the material.

[0027] The porosity of the block is uniform, and the gas distribution performance of the intake manifold can be improved by adjusting the thickness of the block.

Embodiment 3

[0029] The blocking block is composed of multiple sub-blocks arranged at even intervals along the air intake direction, and the height of the blocking block increases along the air intake direction.

[0030] The sub-block is composed of front and rear fixing plates and cylindrical blocks. Several pairs of locking protrusions are symmetrically arranged on the inner surfaces of the front and rear fixing plates, and the cylindrical blocks are arranged horizontally. , the size of the front and rear fixed blocks is configured with the inner cavity of the intake manifold, and is installed in cooperation with the clearance of the intake manifold, and the number of cylindrical blocks on the multiple sub-blocks increases along the intake direction. The thickness of the front and rear fixing plates is as small as possible, and they are integrated with the cylindrical block and then embedded in the inner cavity of the intake manifold. The installation is stable and the position will not b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com