Molten carbonate fuel cell sealing structure and preparation method and application thereof

A technology of molten carbonate and fuel cells, which is applied in the direction of molten electrolyte fuel cells, fuel cells, and fuel cell components, etc., can solve the problems of poor sealing and high stack density, achieve good sealing and improve power. Density, the effect of reducing the risk of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

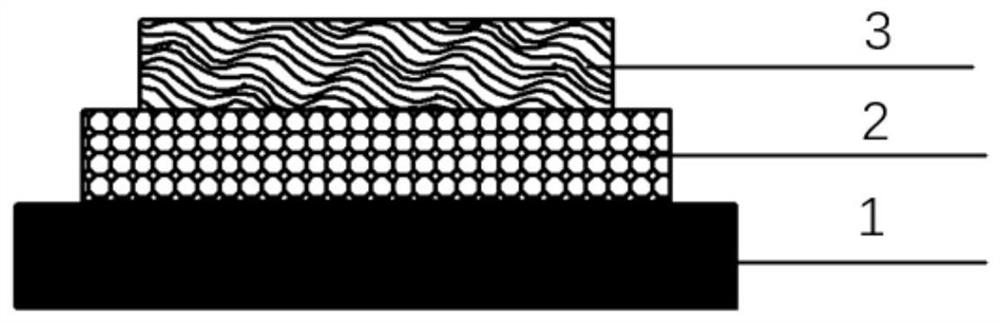

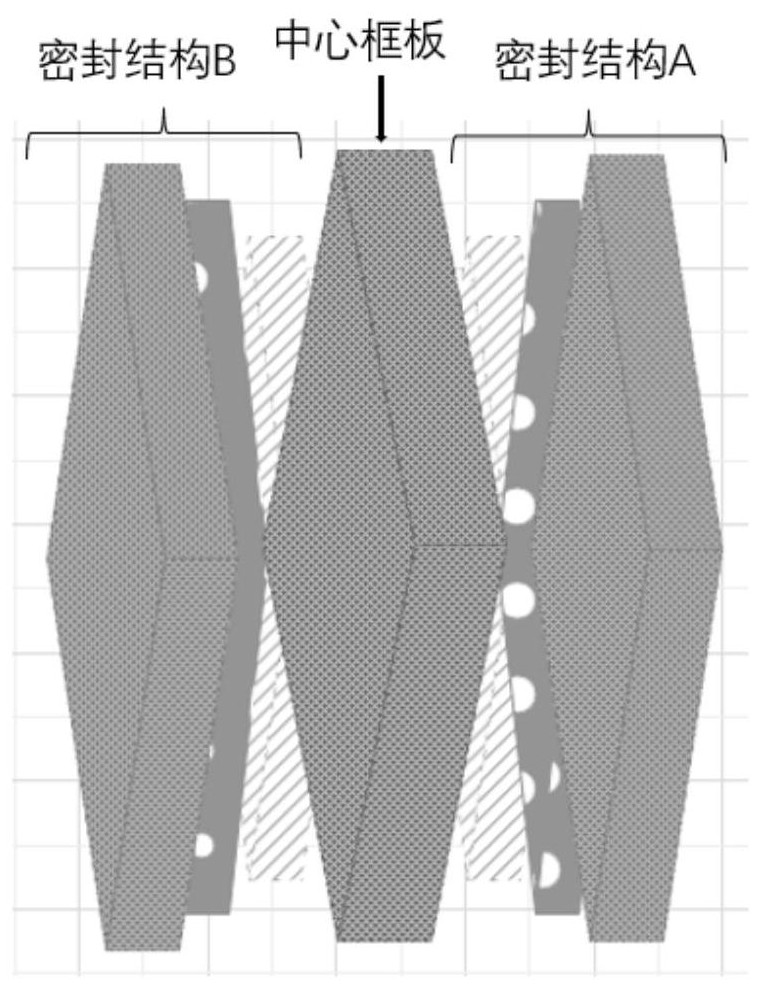

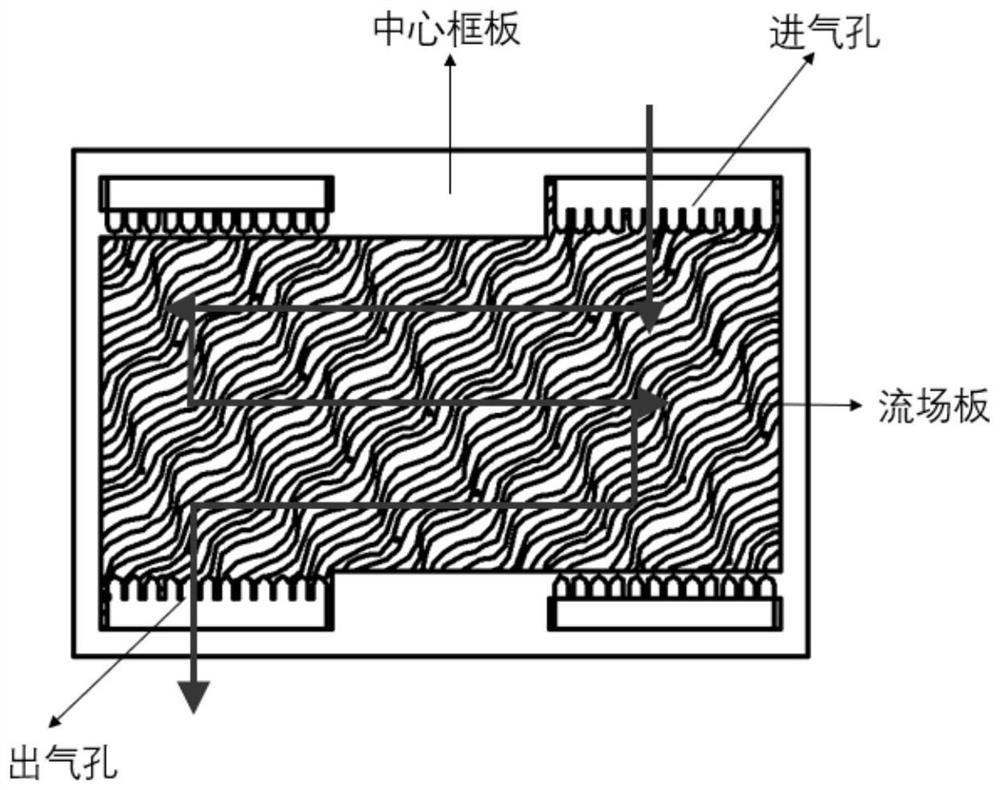

[0050] This embodiment provides a sealing structure for a molten carbonate fuel cell, which is denoted as A, specifically as figure 1 As shown, according to the order of the diagonal size from large to small, it includes the electrode 1, the punching plate 2 and the flow field plate 3 which are arranged in sequence; the punching plate 2 is arranged between the flow field plate 3 and the electrode 1 to play The function of supporting the electrode and collecting current; the electrode 1, the punching plate 2 and the flow field plate 3 are rectangular.

[0051] Based on the diagonal line, the size of the electrode is 819mm, the size of the punching plate is 778mm, and the size of the flow field plate is 696mm; the thickness of the electrode is 0.8mm, the thickness of the punching plate is 0.6mm, and the thickness of the flow field plate is 2mm.

[0052] The perforated plate is made of stainless steel, with a number of round holes for filling electrolyte. The porosity of the per...

Embodiment 2

[0058] This embodiment provides a sealing structure for a molten carbonate fuel cell, which is denoted as B, and includes an electrode 1, a punching plate 2 and a flow field plate 3 that are stacked in sequence; the punching plate 2 is arranged on the flow field plate The space between 3 and electrode 1 can support the electrode and collect current; the electrode 1, punching plate 2 and flow field plate 3 are rectangular.

[0059] Based on the diagonal line, the size of the electrode is 819mm, the size of the punching plate is 778mm, and the size of the flow field plate is 696mm; the thickness of the electrode is 0.8mm, the thickness of the punching plate is 0.6mm, and the thickness of the flow field plate is 2mm.

[0060] The perforated plate is made of stainless steel, with a number of round holes for filling electrolyte. The porosity of the perforated plate is 60%; the flow field plate is made of stainless steel, and there are flow channels in the flow field plate, and the ...

Embodiment 3

[0066] This embodiment provides a sealing structure for a molten carbonate fuel cell, the sealing structure is denoted as C, and includes an electrode 1, a punching plate 2 and a flow field plate 3 that are stacked in sequence; the punching plate 2 is arranged on the flow field plate The space between 3 and electrode 1 can support the electrode and collect current; the electrode 1, punching plate 2 and flow field plate 3 are rectangular.

[0067] Based on the diagonal line, the size of the electrode is 820mm, the size of the punching plate is 697mm, and the size of the flow field plate is 615mm; the thickness of the electrode is 1mm, the thickness of the punching plate is 1mm, and the thickness of the flow field plate is 2mm .

[0068] The perforated plate is made of stainless steel, with a number of round holes for filling electrolyte. The porosity of the perforated plate is 60%; the flow field plate is made of stainless steel, and there are flow channels in the flow field pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com