Fuel cell module, fuel cell system, fuel cell power system and vehicle

A technology of fuel cells and electric stacks, applied in the direction of fuel cells, fuel cell grouping, fuel cell additives, etc., can solve problems such as uneven heat dissipation, low power, overheating of single-chip batteries, etc., to increase volumetric power density and reduce complexity performance, high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

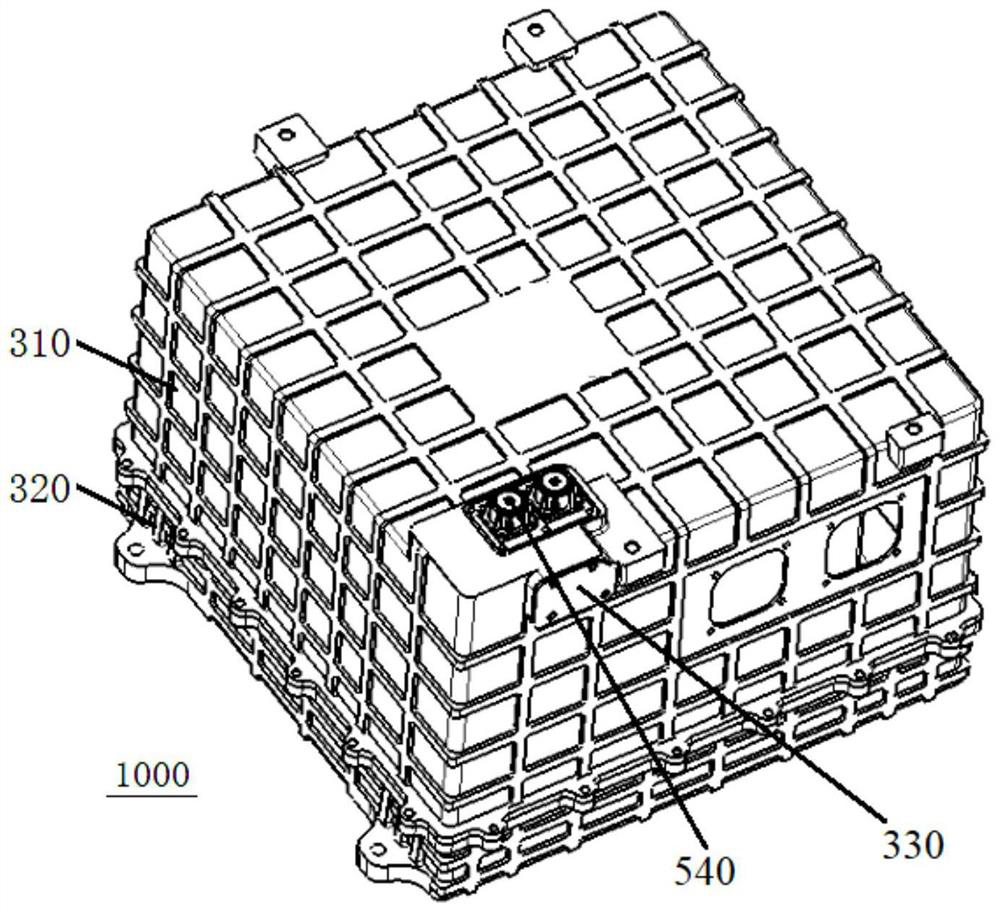

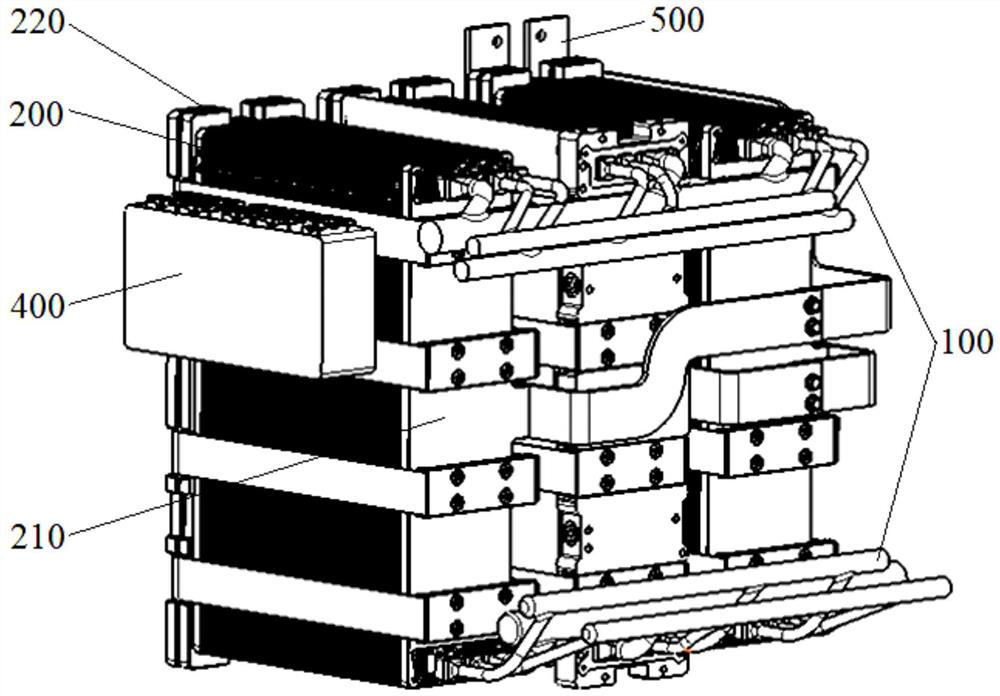

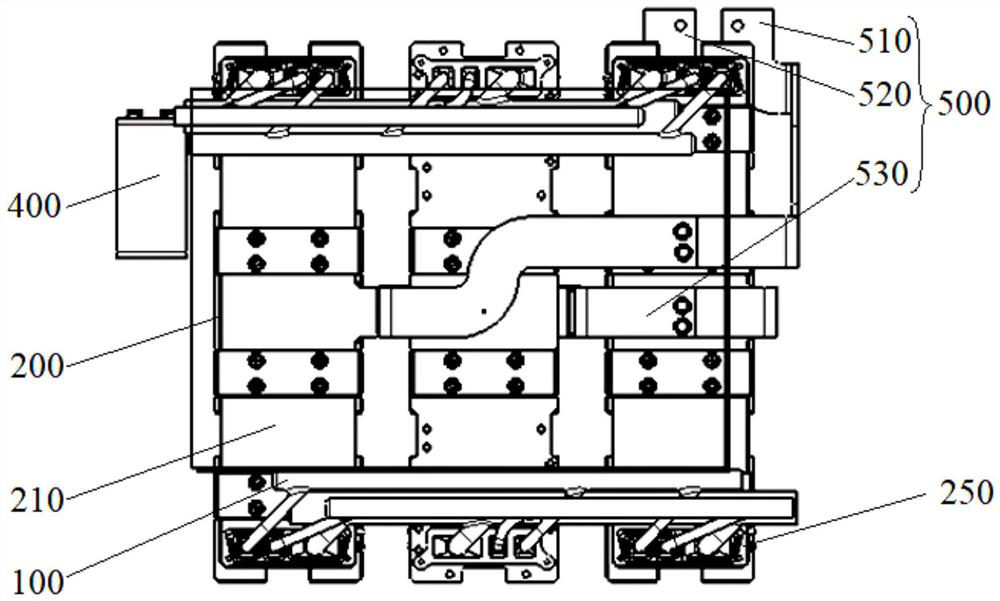

[0086] Embodiments of the present application provide a fuel cell module 1000, the structure of which is as follows Figure 1 to Figure 6 As shown, the fuel cell module 1000 adopts a multi-stack integration solution, including more than two cell stacks 200 . That is to say, the fuel cell module 1000 may adopt solutions such as dual-stack integration, three-stack integration, four-stack integration, and six-stack integration. The stacks 200 of the fuel cell module 1000 are arranged parallel to the short side direction of the bipolar plates in the stack 200, that is to say, the stacks 200 of the fuel cell module 1000 are placed vertically or sideways, and are arranged along the The short-side direction of the bipolar plate is spaced apart, and the inter-stack spacing is used for wiring, arranging high-voltage copper bars and other parts. In this embodiment, the fuel cell module 1000 includes three stacks 200, and the number of repeating units (bipolar plates + membrane electrod...

Embodiment 2

[0125] Based on the same inventive concept, an embodiment of the present application provides a fuel cell module 1000, the structure of which is as follows Figure 18 to Figure 21 As shown, the fuel cell module 1000 adopts a multi-stack integration solution, including more than two cell stacks 200 . That is to say, the fuel cell module 1000 can adopt solutions such as dual-stack integration, three-stack integration, four-stack integration, and six-stack integration. The stacks 200 of the fuel cell module 1000 are arranged parallel to the short side direction of the bipolar plates in the stack 200, that is to say, the stacks 200 of the fuel cell module 1000 are placed vertically or sideways, and are arranged along the The short-side direction of the bipolar plate is spaced apart, and the inter-stack spacing is used for wiring, arranging high-voltage copper bars and other parts. In this embodiment, the fuel cell module 1000 includes three stacks 200, and the number of repeating...

Embodiment 3

[0133] Based on the same inventive concept, this embodiment provides a fuel cell system. For details, please refer to Figure 22 , the fuel cell system includes a fuel cell module and a fuel cell auxiliary system, and the fuel cell system can work normally under the condition of an external fuel supply source. The fuel cell module in the fuel cell system may adopt the fuel cell module of the above-mentioned Embodiment 1 or Embodiment 2, and the specific content will not be repeated here.

[0134] The fuel cell auxiliary system includes an air supply subsystem, a fuel supply subsystem, a thermal management subsystem and an automatic control system, wherein the air supply subsystem is used to provide air to each stack of the fuel cell module, and can optionally filter the air, For humidification, pressure regulation, etc., the air supply subsystem is communicated with the air inlet and air outlet of each stack of the fuel cell module; the fuel supply subsystem is used to provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com