Automatic dropwise adding reaction device

A dropwise reaction, automatic technology, applied in chemical/physical/physical-chemical nozzle reactors, chemical/physical/physical-chemical processes, chemical instruments and methods, etc. Problems such as low safety performance, to achieve the effect of small transformation impact, reduced response time, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below with reference to the accompanying drawings and embodiments.

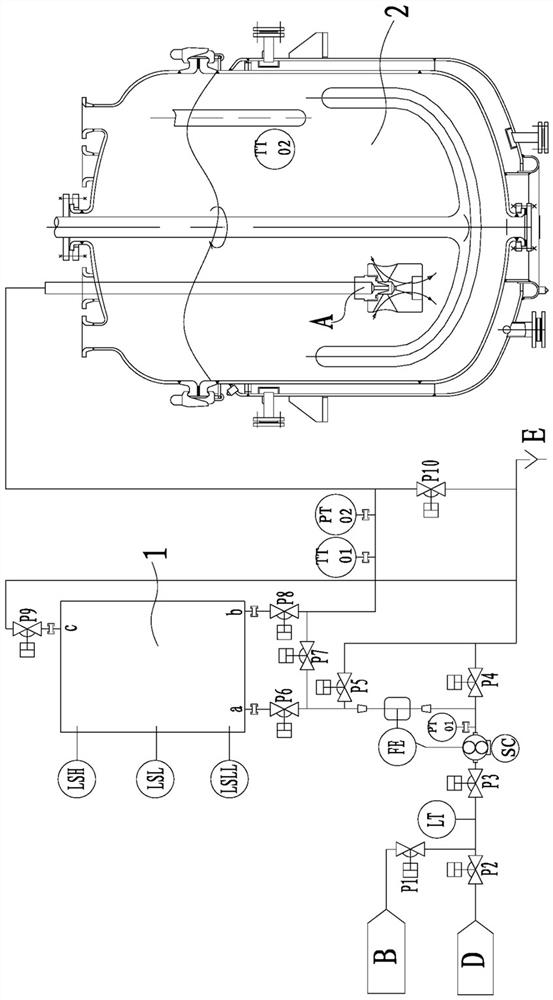

[0043] refer to figure 1 , the present invention includes a bubble trap box 1 and a reactor 2.

[0044] The bubble trap box 1 is provided with a high liquid level switch LSH in the upper part, a low liquid level switch LSL in the middle, and a low and low liquid level switch LSLL in the lower part. The high liquid level switch LSH, the low liquid level switch LSL, and the low and low liquid level switch LSLL are connected with a programmable logic controller (PLC) with electrical signals.

[0045] Described reactor 2 is placed with atomizing nozzle A, this atomizing nozzle A is connected with the input port of reactor 2 through pipelines, and this atomizing nozzle A is placed in the inner groove of reactor 2 agitators, and is placed in the below the liquid level.

[0046] A temperature sensor TT02 is also installed in the reactor 2, and the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com