Safety belt force reducing device

A seat belt and power wheel technology, applied in the field of seat belt force reduction device, can solve the problems of poor comfort, achieve the effect of convenient operation and improve the comfort of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

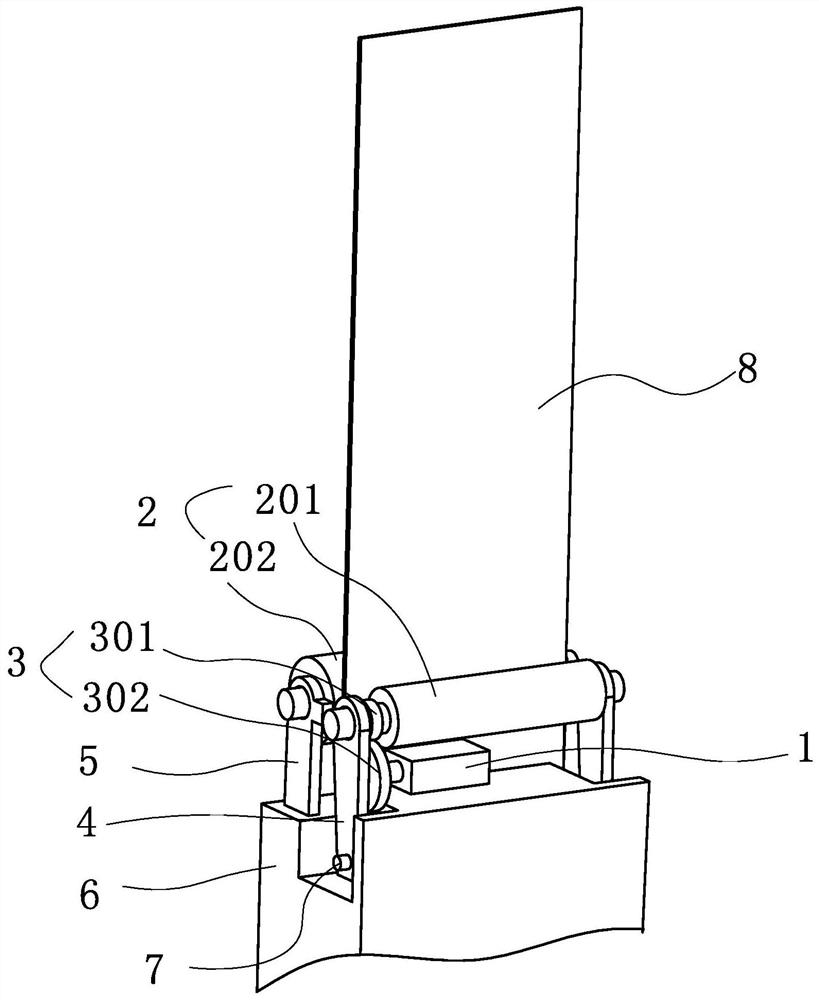

[0035] Such as figure 1 In the shown embodiment 1, a safety belt force reducing device includes a force reducing mechanism 10 and a fixing seat 6, the force reducing mechanism 10 is installed on the fixing seat 6, and the fixing seat 6 is arranged at the outlet of the retractor 11, namely The force reduction mechanism 10 is arranged at the exit of the retractor 11, which is convenient for controlling the webbing 8 when the ribbon 8 is pulled out; the force reduction mechanism 10 includes a force reduction wheel assembly 2, a motor 1 and a control assembly, wherein the force reduction wheel assembly 2 includes The driving wheel 201 and the driven wheel 202, the driving wheel 201 and the driven wheel 202 are respectively arranged on both sides of the webbing, the auxiliary webbing 8 is pulled out and recovered, the driving wheel 201 is connected to the motor 1, and the control assembly includes a motor for detecting the motion state of the webbing 8 A sensor and a controller for...

Embodiment 2

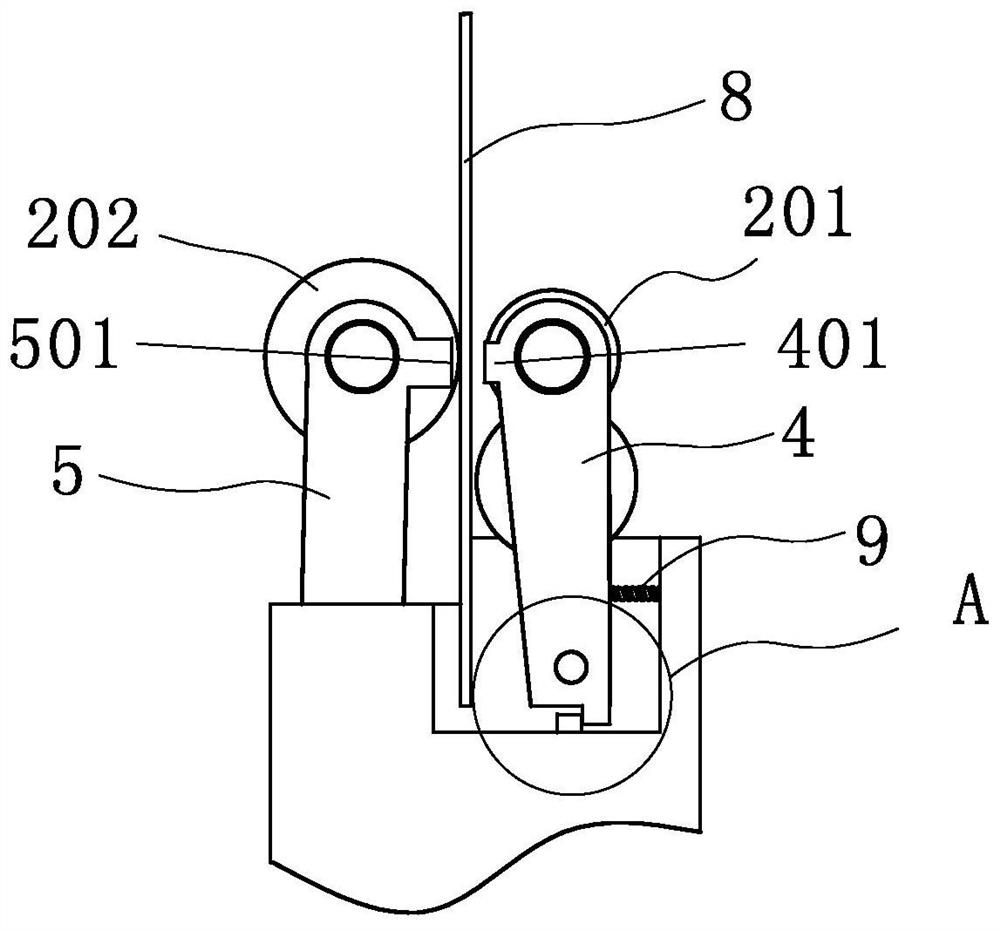

[0040] Such as figure 2 , Figure 5 As shown, the technical solution of embodiment 2 is basically the same as the technical solution of embodiment 1, the difference is that it also includes a support plate 5 and a fixed plate, and the two ends of the driven wheel 202 are respectively fixed on the two support plates 5 to drive Both ends of the wheel 201 are respectively fixed on two rotating plates 4, and the supporting plate 5 and the rotating plate 4 are respectively used to fix the driving wheel 201 and the driven wheel 202, so as to control the distance between the driving wheel 201 and the driven wheel 202.

[0041] Further, a stop tooth 501 is provided on the support plate 5, a limit tooth 401 corresponding to the stop tooth 501 is provided on the rotating plate 4, the stop tooth 501 is set as an electromagnet, and the lower side of the rotating plate 4 is connected to the A rotating structure is arranged between the fixed bases 6, and the rotating structure includes a ...

Embodiment 3

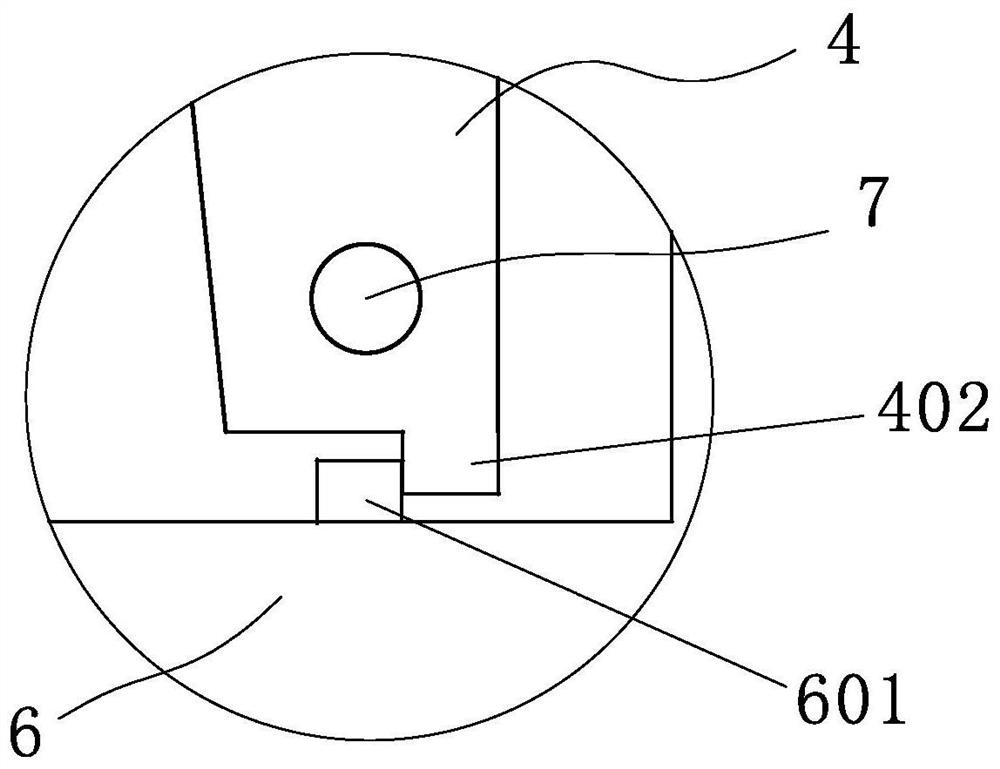

[0044] Such as image 3 As shown, the technical solution of embodiment 3 is basically the same as the technical solution of embodiment 2, the difference is that: the lower end of the rotating plate 4 is provided with a limiting structure for controlling the rotation angle of the rotating plate 4, and the limiting structure includes a The limit protrusion 402 at the lower end of the rotating wheel corresponds to the limit block 601 arranged on the fixed seat 6. The limit protrusion 402 and the limit block 601 control the rotation range of the rotating plate 4, avoiding the rotation of the rotating plate 4 during the reset process. Larger swings in the middle cause inconvenience.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com