Step-by-step reaction type metal fuel cell system

A metal fuel cell and fuel cell technology, applied in fuel cells, fuel cell additives, fuel cell half-cells, and secondary battery-type half-cells, can solve problems such as electrolyte drying up and meet energy density requirements And low cost, high energy density and low cost, eliminate the effect of corrosion reaction

Active Publication Date: 2020-06-05

JINGMEN CITY DREAM EXPLORATION TECH CO LTD

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0010] The present invention aims at the deficiencies of the above-mentioned prior art, and provides a step-by-step reaction metal fuel cell system. By adopting a step-by-step reaction method, the metal-air battery reaction is divided into two steps, and the metal anode reaction part is in a clo

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

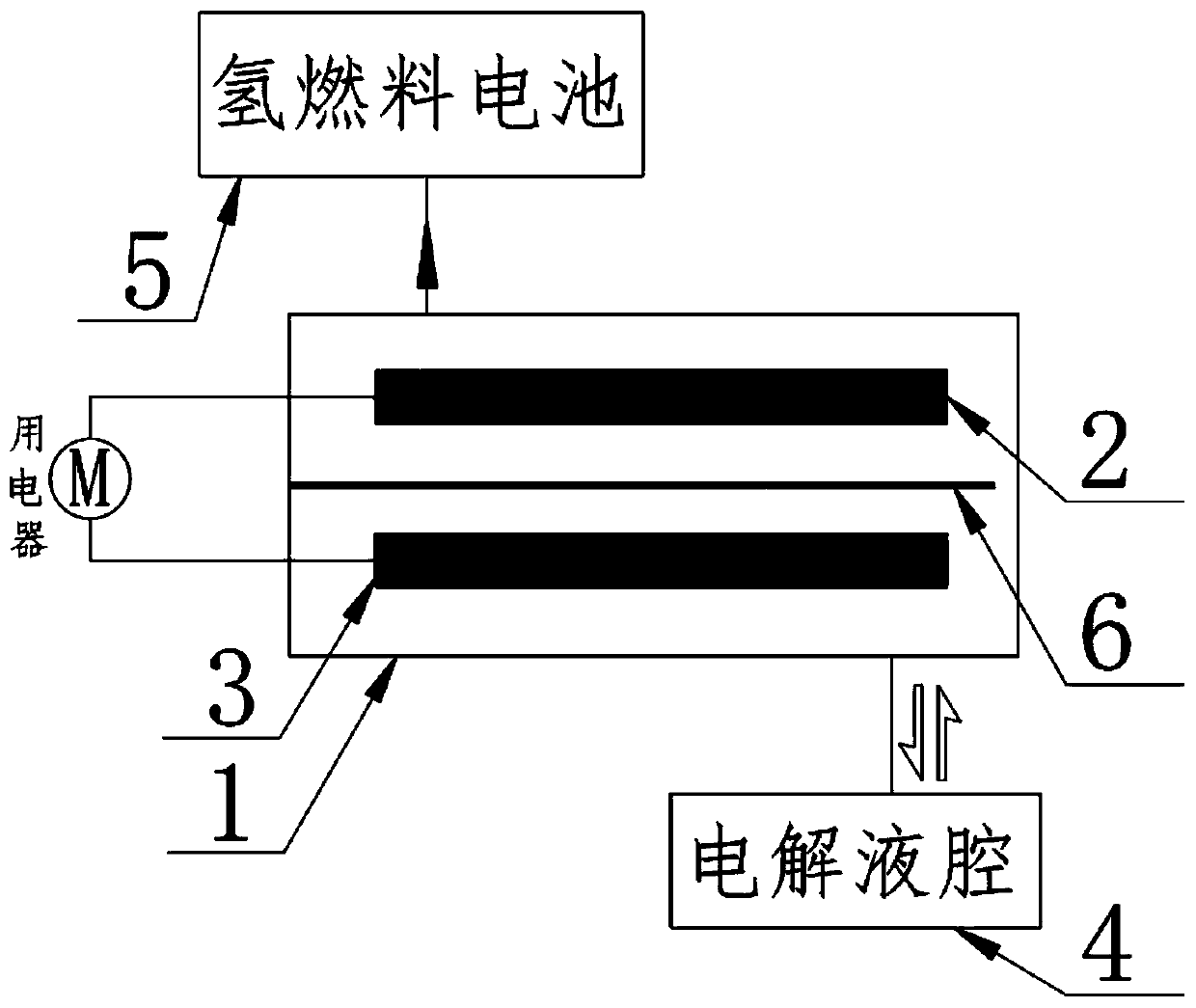

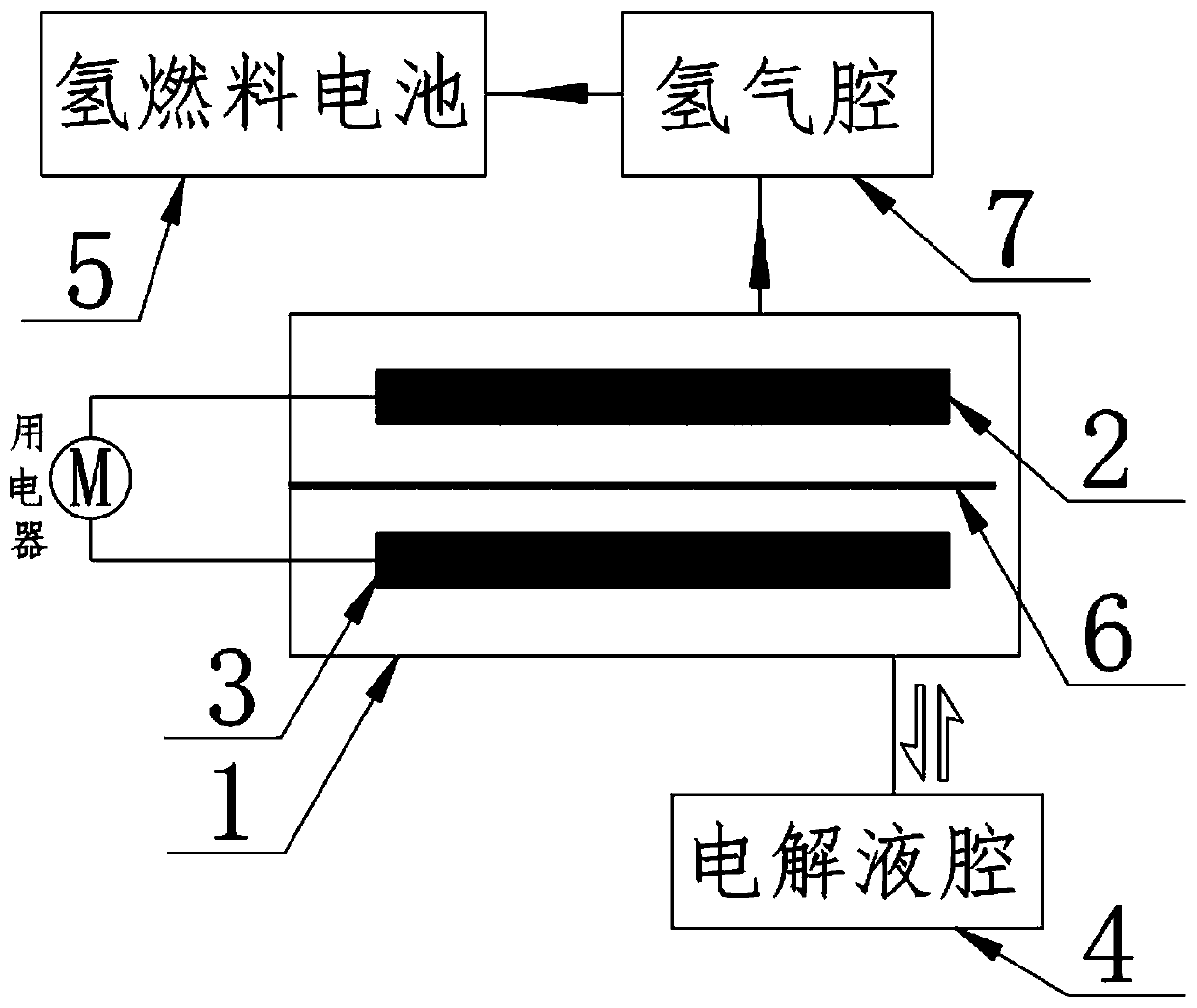

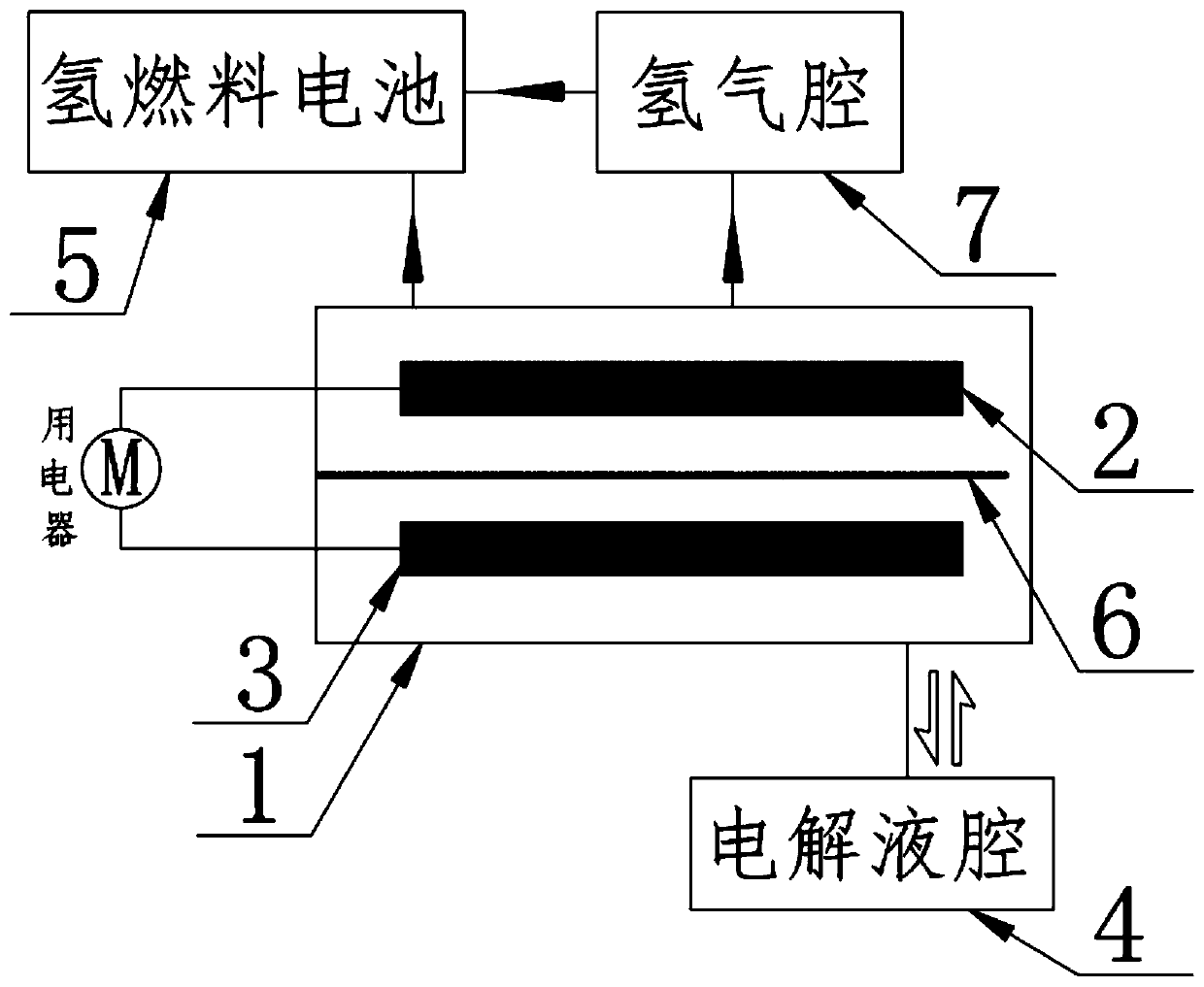

The invention relates to the field of new energy, and discloses a step-by-step reaction type metal fuel cell system. The system comprises a reaction cavity, a water electrode, a metal electrode, an electrolyte cavity and a hydrogen fuel cell; the water electrode and the metal electrode are respectively positioned in the reaction cavity and are respectively led out of the reaction cavity through leads; the reaction cavity is connected with the electrolyte cavity through a pipeline; and an electrolyte is contained in the electrolyte cavity. A hydrogen source is provided for the hydrogen fuel cell through reaction in the reaction cavity, a step-by-step reaction mode is adopted, the reaction of the metal-air battery is divided into two steps, the metal anode reaction part is in a closed environment, the problems of electrolyte drying and alkali leakage are solved, and then the valve between the reaction cavity and the hydrogen cavity is closed, so that the hydrogen generated in the reaction cavity can be gathered in the reaction cavity, the pressure in the reaction cavity is increased, the electrolyte is pressed back into the electrolyte cavity, the metal anode is separated from the electrolyte and is positioned in a reduction protection atmosphere of the hydrogen, and the occurrence of corrosion reaction can be completely avoided.

Description

technical field [0001] The invention relates to the field of new energy, in particular to a step-by-step reaction type metal fuel cell system. Background technique [0002] In order to solve the environmental problems and energy crisis caused by traditional fossil fuels, countries are currently vigorously developing new energy technologies, and many European countries have given a ban on the sale of fuel vehicles. [0003] Among many new energy technologies, lithium battery technology is currently the fastest-growing new energy technology. However, due to the constraints of the chemical system of the lithium battery itself, its disadvantages are very obvious, and it cannot compete with the fuel energy system in many cases. First of all, the charging time of lithium batteries usually takes tens of minutes to several hours, which greatly reduces the convenience; second, the theoretical energy density of lithium batteries is only 240Wh / Kg~350Wh / Kg, which is far lower than the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M12/08H01M10/28H01M10/38H01M8/04082H01M8/04089

CPCH01M8/04089H01M8/04201H01M10/288H01M10/38H01M12/08Y02E60/10Y02E60/50Y02P70/50

Inventor 王广军余为伟

Owner JINGMEN CITY DREAM EXPLORATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com