An easy-to-use rust removal device for metal surfaces

A metal surface and support plate technology, which is applied in the direction of grinding drive devices, metal processing equipment, grinding machine parts, etc., can solve the problems of affecting the user's production efficiency, poor derusting effect of tubular metal, and time-consuming, etc., to achieve Good rust removal function, simple structure, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

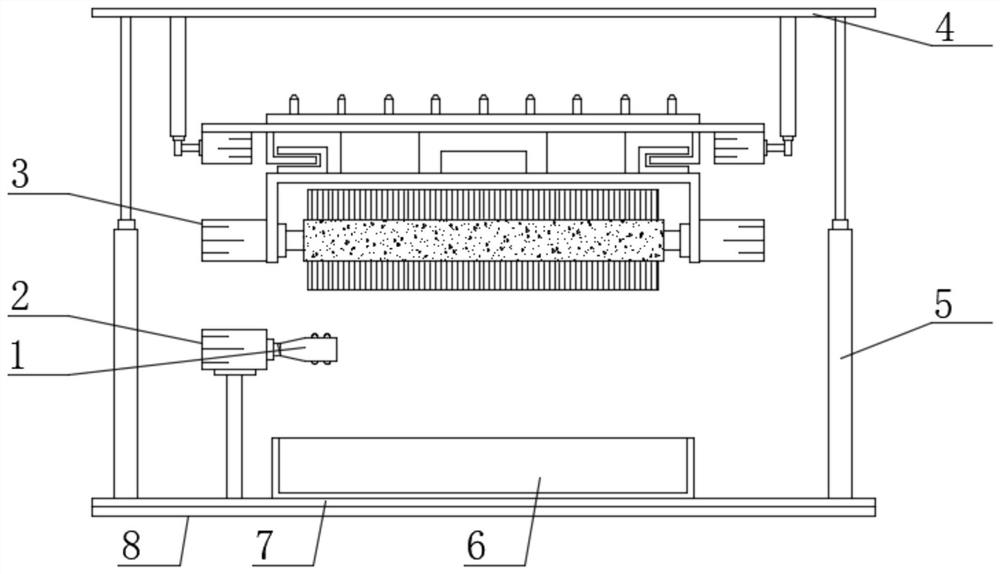

[0023] see Figure 1-Figure 3 , the present invention provides a technical solution: an easy-to-use metal surface derusting device, comprising a second support plate 7, one end of the upper surface of the second support plate 7 is fixed with a first drive motor 2 by bolts, the first drive motor The output end of 2 is provided with fixing device 1, and the use of first driving motor 2 and fixing device 1 is prior art, and the top of second supporting plate 7 is provided with first supporting plate 4, and the upper surface of second supporting plate 7 The first electric telescopic rod 5 corresponding to the first support plate 4 is welded at both ends, and a derusting mechanism 3 is arranged under the first support plate 4;

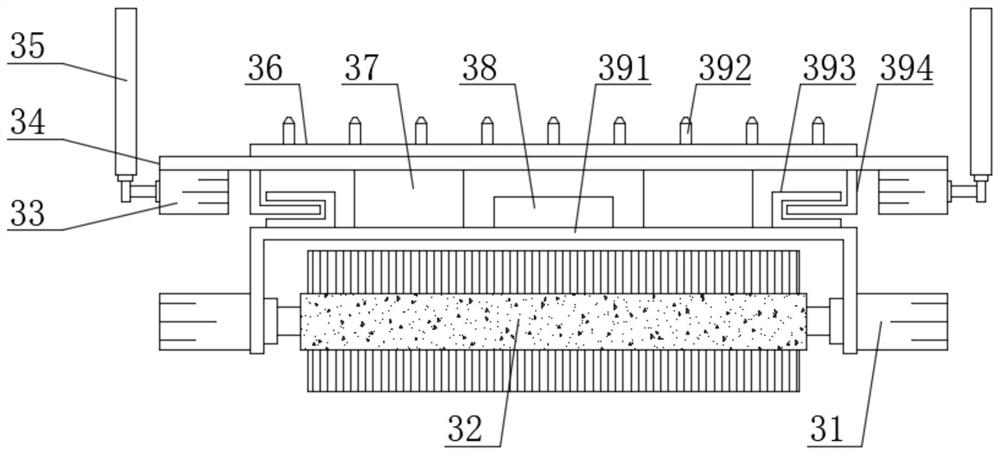

[0024] Derusting mechanism 3 comprises the 3rd support plate 34, the 3rd drive motor 33 is arranged on the lower surface two ends of the 3rd support plate 34, the output end of the 3rd drive motor 33 is provided with the second drive motor 33 corresponding ...

Embodiment 2

[0033] On the basis of Embodiment 1, in order to enrich the function of the derusting device, in this embodiment, preferably, the upper surface of the second support plate 7 is provided with a collection box 6, and the material of the collection box 6 is plastic. The used derusting solution is collected and stored through the collection box 6 to prevent the derusting device from flowing out a large amount of derusting solution during use;

[0034] In order to make the anti-slip effect of the derusting device better, in the present embodiment, preferably, the lower surface of the second support plate 7 is provided with an anti-slip backing plate 8, the anti-slip backing plate 8 is a cuboid structure, and the anti-slip backing plate 8 and the second support Board 7 is connected by glue bonding;

[0035] The material of anti-slip backing plate 8 is not limited, and in the present embodiment, preferred, the material of anti-slip backing plate 8 is rubber, plays anti-slip effect by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com