A kind of solid rocket motor thermal insulation layer automatic winding equipment and using method thereof

A solid rocket and engine technology, applied in metal processing, etc., can solve the problems that cannot meet the requirements of automatic winding and forming of the rubber insulation layer of solid rocket motors, and meet the requirements of multi-degree-of-freedom control, avoid excessive winding tension, and avoid tape contact pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

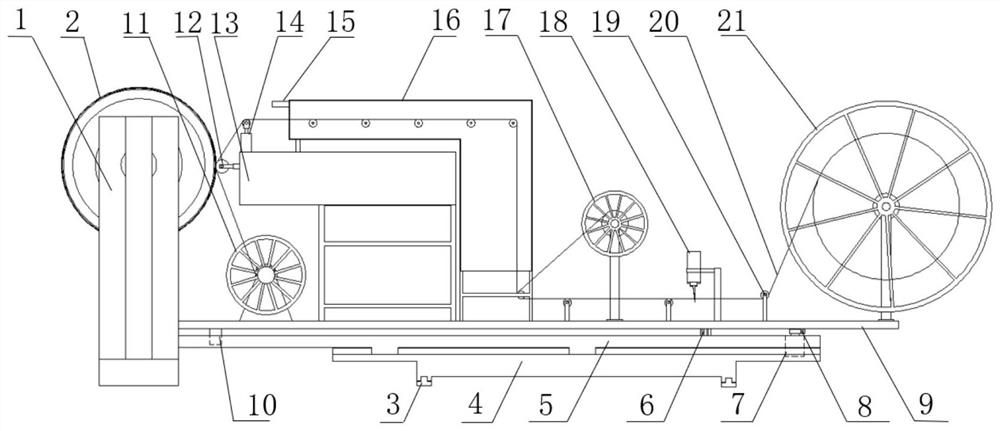

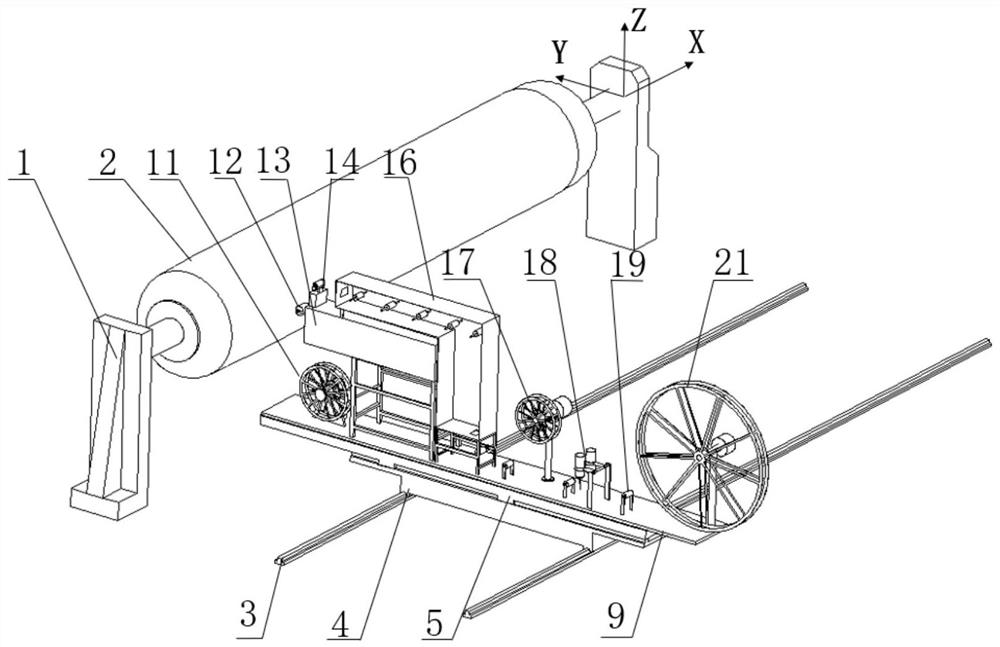

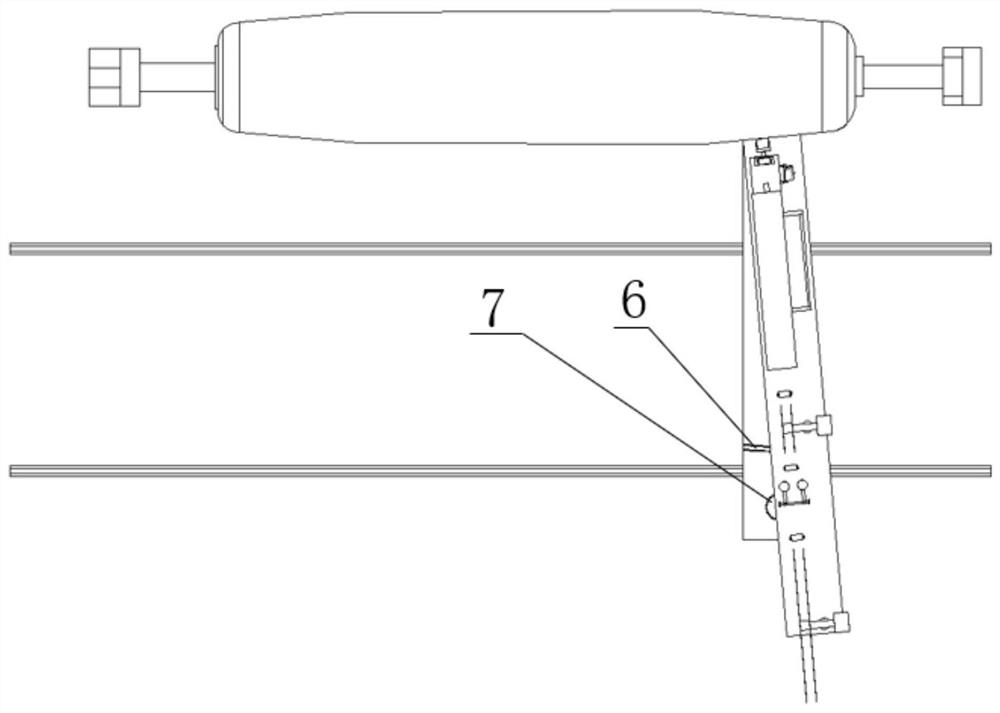

[0041] This embodiment relates to a kind of solid rocket motor insulation layer automatic winding equipment, such as figure 1 , 2 , shown in 3, mainly includes, a kind of solid rocket motor thermal insulation layer automatic winding equipment, it is characterized in that, mandrel supporting device 1, mandrel 2, lateral (X direction) translation guide rail 3, lateral movement (X direction) relay Platform 4, longitudinal movement (Y direction) relay platform 5, arc-shaped guide rail 6, rotating motor 7, arc-shaped rack 8, rotating platform 9, rotating shaft 10, release film recovery device 11, winding pressure roller 12, winding Laying device 13, correction device 14, tape position detector 15, tape heating device 16, protective film recovery device 17, ultrasonic cutting device 18, tape guide wheel 19, double-backed tape 20, tape reel 21.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com