Load-bearing self-locking mine logistics equipment

A mine and logistics technology, applied in mining equipment, mining vehicles, mining equipment, etc., to achieve the effects of simple structure, improved safety, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

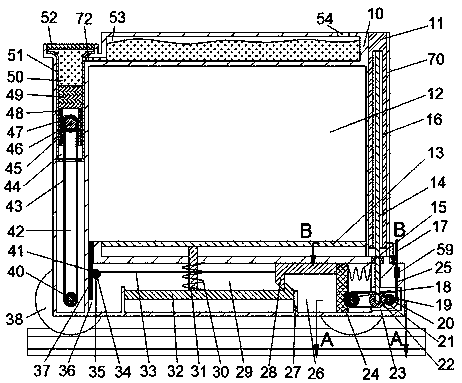

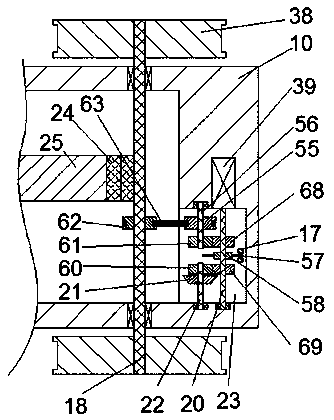

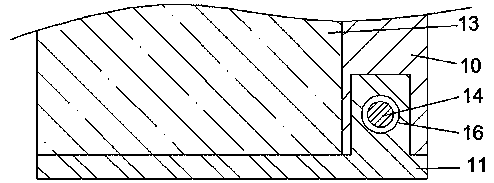

[0021] Combine below Figure 1-6 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are consistent.

[0022] combined with Figure 1-6 The load-bearing self-locking mine logistics equipment includes a vehicle body 10, the vehicle body 10 is provided with a loading chamber 12 with an opening forward, and the inner top wall of the loading chamber 12 is provided with a water tank 53. The inner wall on the left side of the object chamber 12 is provided with a sprinkler tank 51, and the sprinkler tank 51 is provided with a liquid storage chamber 50 that penetrates up and down. The lower side of a transmission chamber 44 is provided with a second transmission chamber 42, and a bearing plate 13 is slidably provided in the loading chamber 12, and a chute 70 with an outward opening is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com