AGV carrying device and method

A handling device and foot post technology, applied in the field of AGV handling devices, can solve the problems of inconvenient access to vehicles and complicated conveying devices, and achieve the effects of cost reduction, good stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

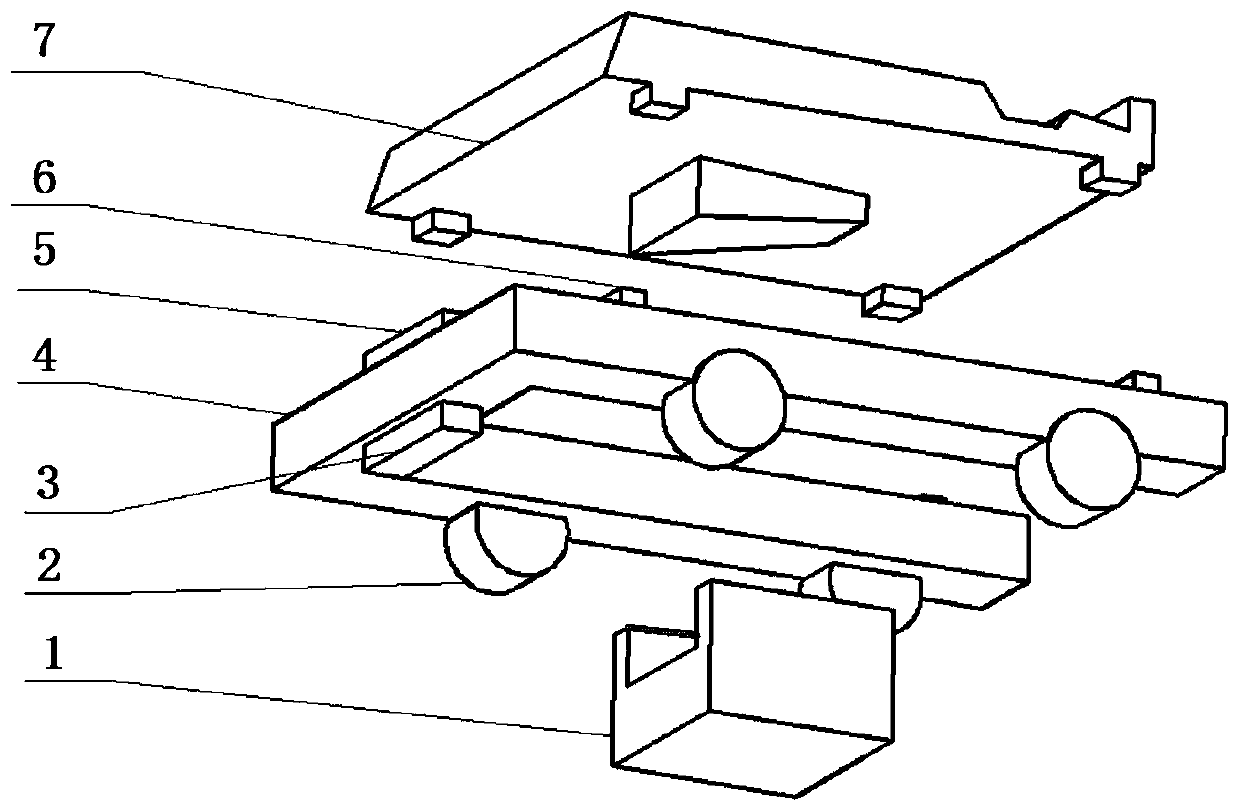

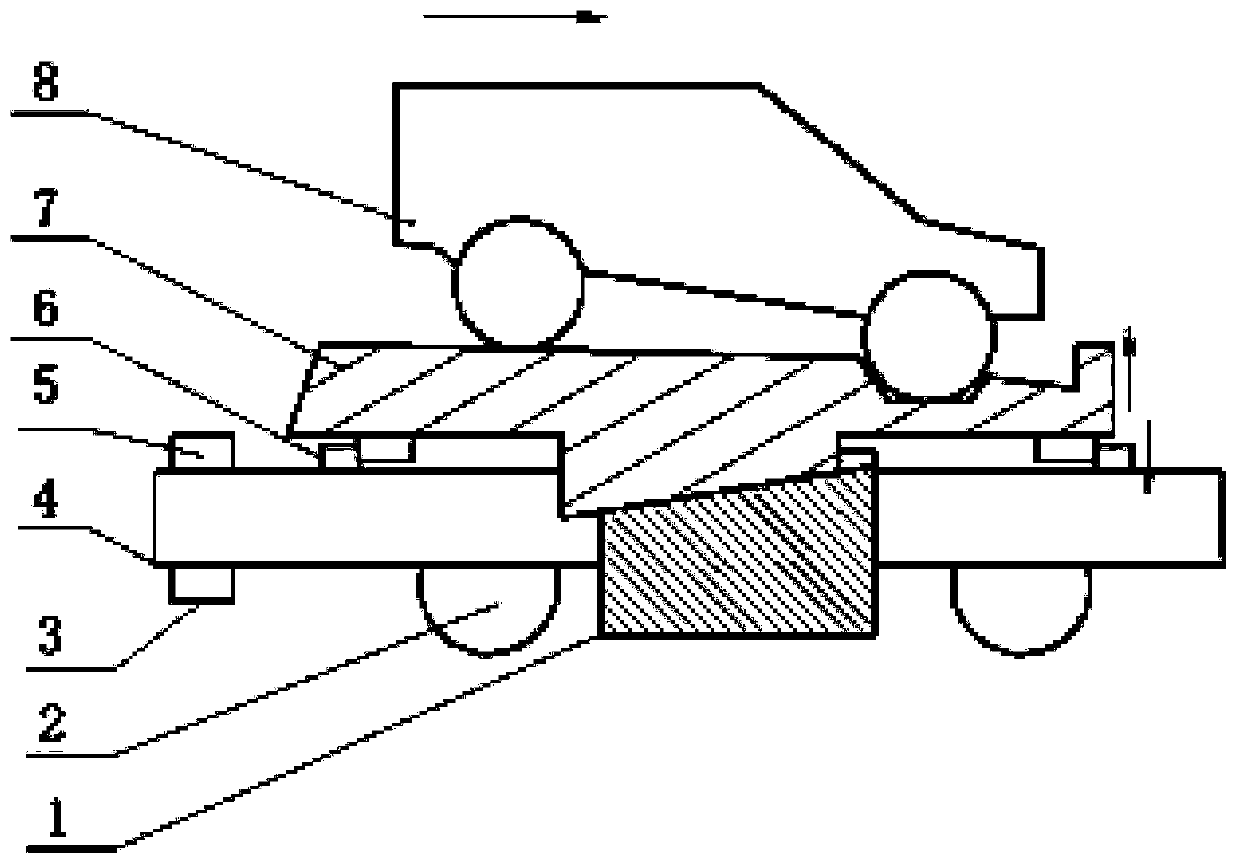

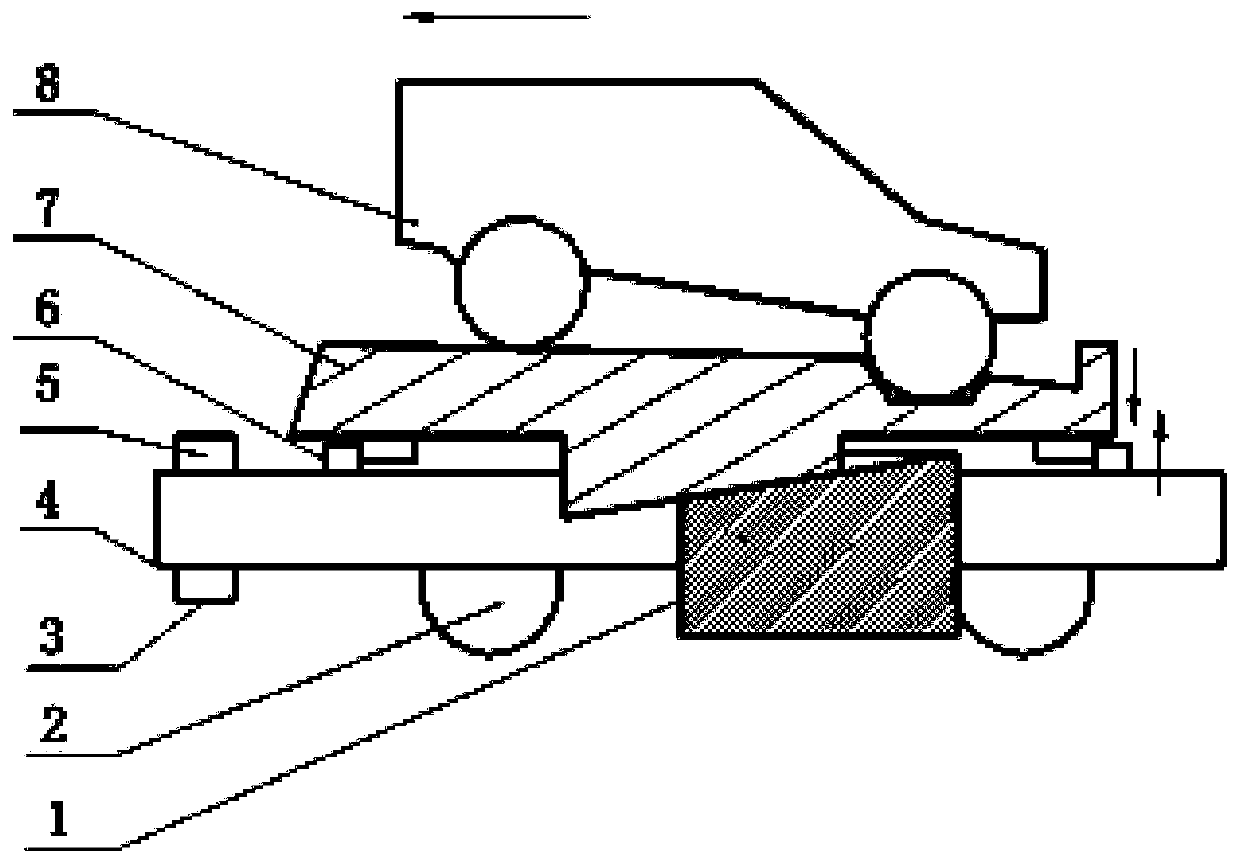

[0031] An AGV handling device for handling heavy loads in and out of the warehouse, such as figure 1 and Figure 6 , including a bracket 7, a trailer and a parking platform 1 arranged in sequence from top to bottom, the trailer includes a carrier board 4 and a control assembly and a drive wheel 2 on the carrier board 4, the carrier board 4 is U-shaped, and the lower surface of the bracket 7 A guide slider 701 and a number of supporting feet 703 are provided. The guide slider 701 contacts the parking platform 1 after passing through the U-shaped notch of the carrier plate 4. The contact surface between the guide slider 701 and the parking platform 1 is a guiding The inclined surface can realize self-locking, guide the inclined surface from low to high along the storage direction, and at least 2 liftable stoppers 6 are provided on the carrier board 4, and the two stoppers 6 are respectively close to the supporting feet 703 towards the storage direction side and the side facing ...

Embodiment 2

[0039] This embodiment proposes a handling method for the handling device of an AGV handling device corresponding to Embodiment 1, which is used for the out and in of the vehicle 8, specifically:

[0040] The vehicle 8 is placed on the bracket 7, the front wheel of the vehicle 8 is placed in the fixed groove 702 on the bracket 7, the bracket 7 is placed on the carrier plate 4 through 4 supporting feet 703 at the bottom, and the controller 5. Control all the stoppers 6 to protrude, and the stoppers 6 limit the four supporting legs 703 to fix the bracket 7;

[0041] The process of placing the vehicle 8 on the bracket 7 is as follows: set up two platforms with a height difference, the vehicle 8 is placed on the high platform, the trailer is placed on the low platform, the bracket 7 is placed on the trailer and the bracket 7 Just level with the elevated platform, the vehicle 8 is moved onto the carriage 7 .

[0042] Such as figure 2 When entering the warehouse, the controller 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com