Valve with linkage type switches

A linkage type, switch technology, applied in valve details, multi-way valve, valve device and other directions, can solve the problem of unable to achieve cyclic reciprocating liquid supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

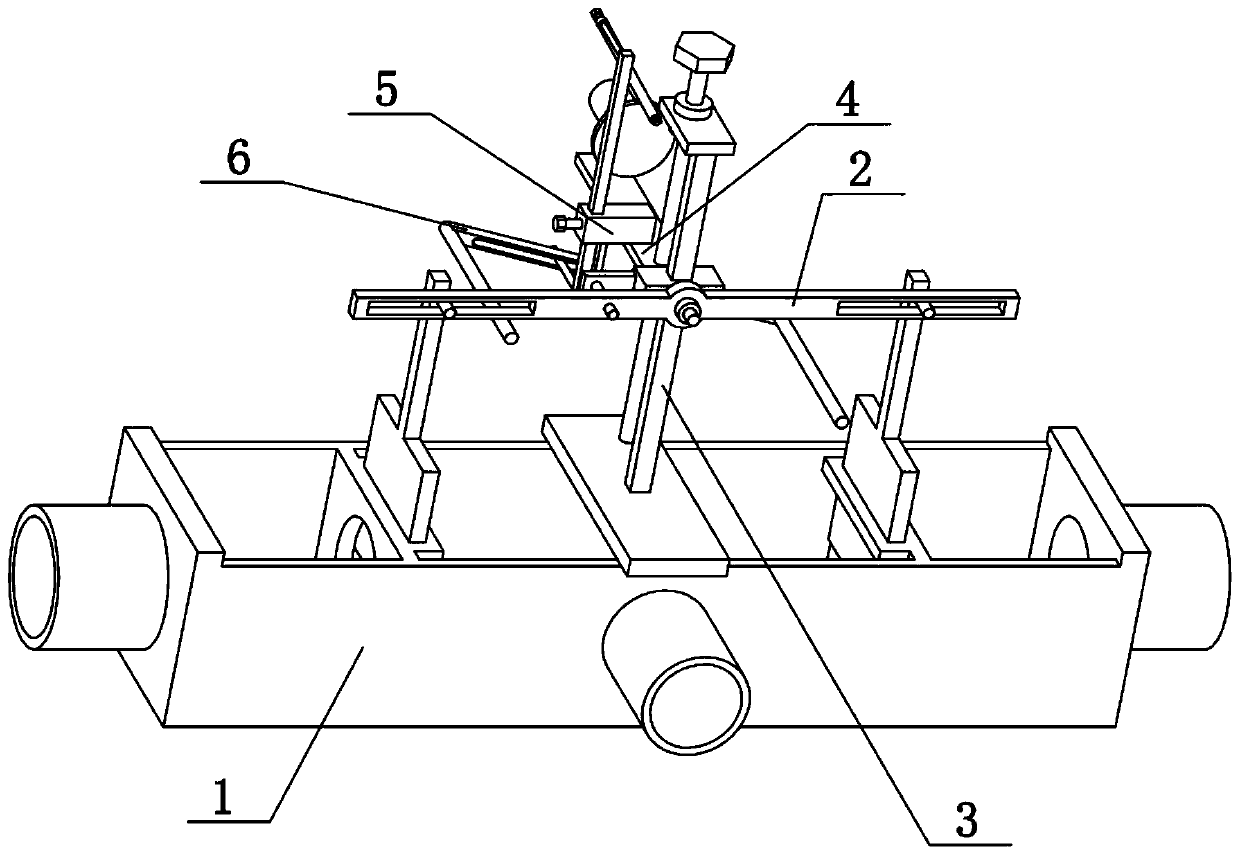

[0028] Combine below Figure 1-7 Description of this embodiment, the present invention relates to a valve, more specifically a valve with a linkage switch, including a square cylinder shell 1, a water inlet 101, a water hole 102, a side water outlet 103, a baffle 104, Rectangular sleeve 105, water storage tank 106, lever 2 and gate 204, the present invention is a three-way valve, the two switches of the present invention can be linked, can be opened and closed at the same time; To achieve the effect of reciprocating liquid supply in two directions.

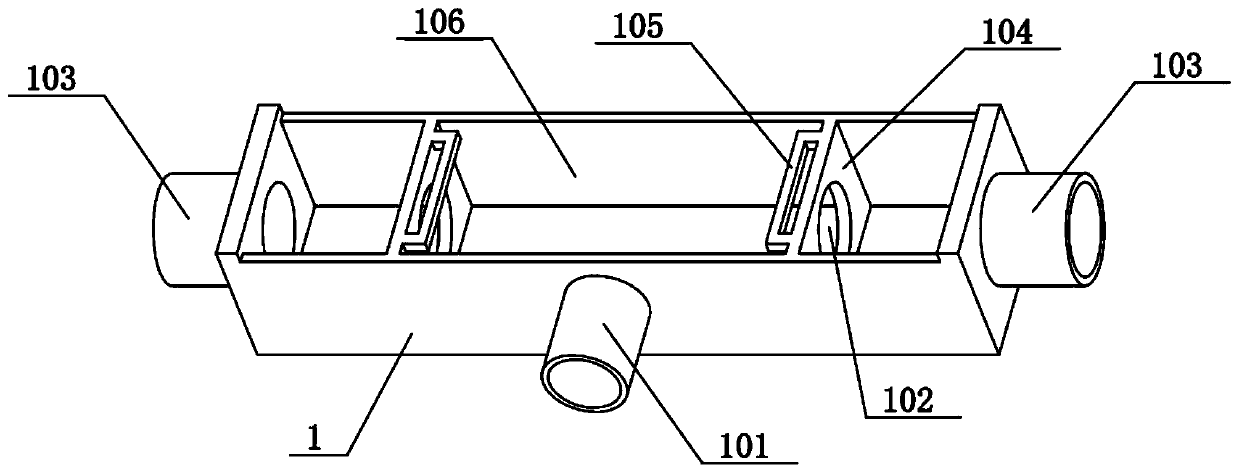

[0029] The square cylinder shell 1 is a hollow cuboid structure, and the inside of the square cylinder shell 1 is symmetrically provided with two baffles 104, and the two baffles 104 are provided with water holes 102 penetrating left and right, and the two baffles The upper ends of 104 are fixedly connected with rectangular sleeves 105, a water storage tank 106 is formed between the two baffles 104, and a water inlet 101 is arran...

specific Embodiment approach 2

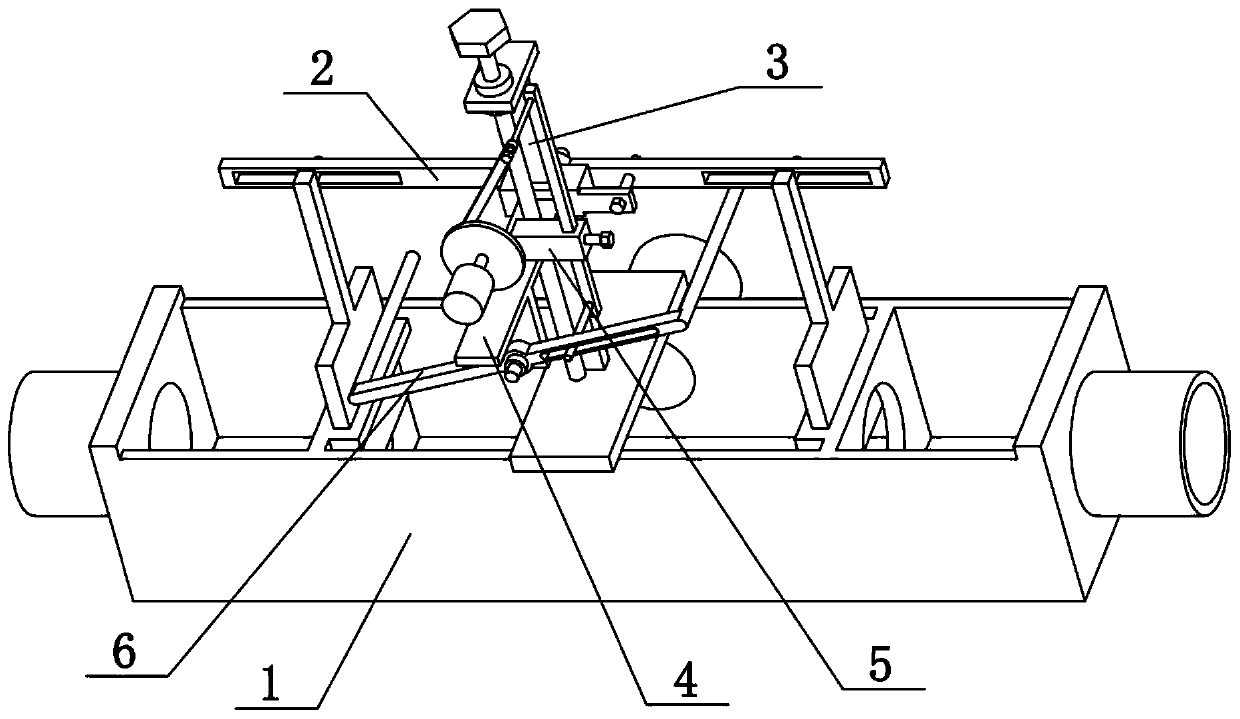

[0031] Combine below Figure 1-7 To illustrate this embodiment, the valve of the linkage switch also includes a sliding hole 202, a vertical column 203 and a fixed column 205, the upper parts of the two gates 204 are fixedly connected with the vertical column 203, and the upper ends of the two vertical columns 203 are fixed A fixed cylinder 205 is connected, and the left and right sides of the lever 2 are provided with sliding holes 202 , and the two fixed cylinders 205 are respectively inserted into the two sliding holes 202 . When the lever 2 is fixed in a horizontal state, when the lever 2 is raised or lowered, the two fixed cylinders 205 are driven up and down, and then the two vertical columns 203 and the two shutters 204 are simultaneously opened and closed. Lift the lever 2 and the two gates 204 upwards by a certain distance, so that the lever 2 rotates around the center of the lever, and then when the lever 2 rotates, it will drive the two fixed cylinders 205 to move i...

specific Embodiment approach 3

[0033] Combine below Figure 1-7 To illustrate this embodiment, the valve of the linkage switch also includes a vertical guide rail 3, a lifting seat 301 and a beam plate 307. The upper middle part of the square cylinder shell 1 is fixedly connected to the beam plate 307, and the upper side of the beam plate 307 is fixedly connected to Vertical guide rail 3 is arranged, vertical slide is connected with lift seat 301 on the vertical guide rail 3, and the middle part of lever 2 is hingedly connected to the front side of lift seat 301. Lifting base 301 can slide up or down on vertical guide rail 3, and lever 2 can be rotated on the front side of lifting base 301, and lifting base 301 raises or lowers and can drive raising or lowering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com