Method for measuring aircraft skin surface state physical characteristics

A technology of surface state and measurement method, which is applied in the field of crack identification and detection technology, and can solve problems such as facility hazards and affecting the performance of aircraft skins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not restricted in any way. Any changes or substitutions made based on the teachings of the present invention belong to the protection scope of the present invention.

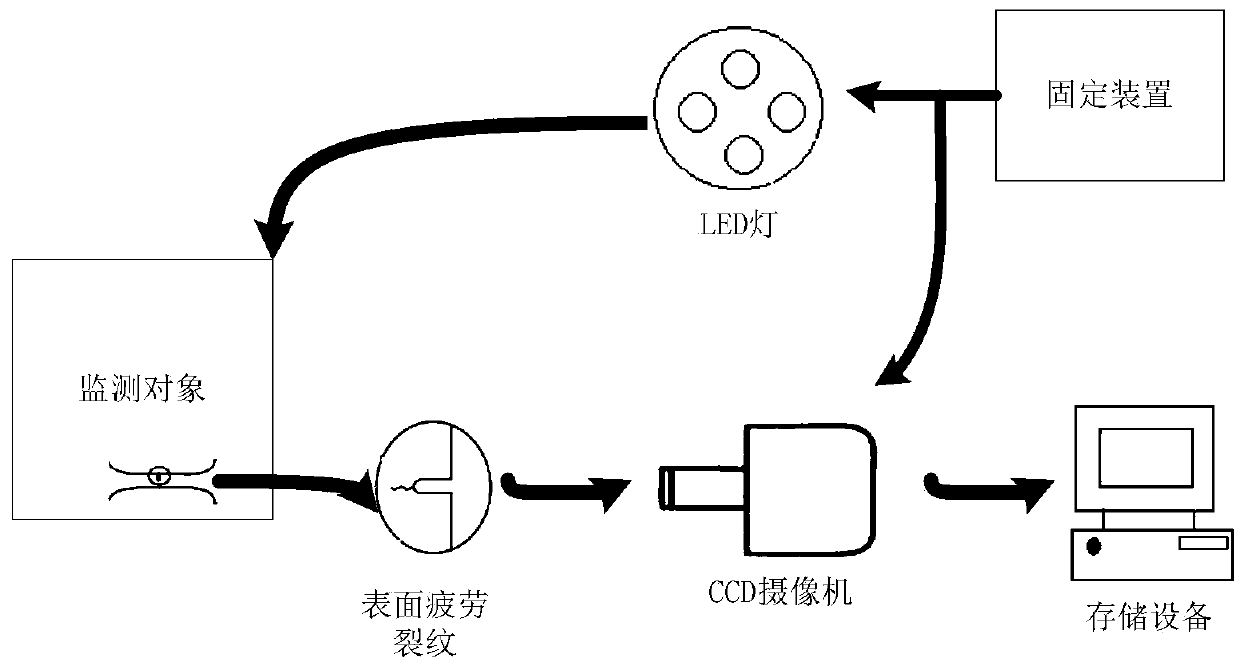

[0048] Such as figure 1 As shown, the image acquisition system is mainly composed of various optical equipment, mechanical instruments and data storage facilities. The image acquisition system is mainly used to acquire the surface crack images of the monitored object and store it for subsequent processing and analysis. The image recognition system is mainly based on software. The image recognition system mainly completes the recognition of characteristic values such as the length and width of surface cracks.

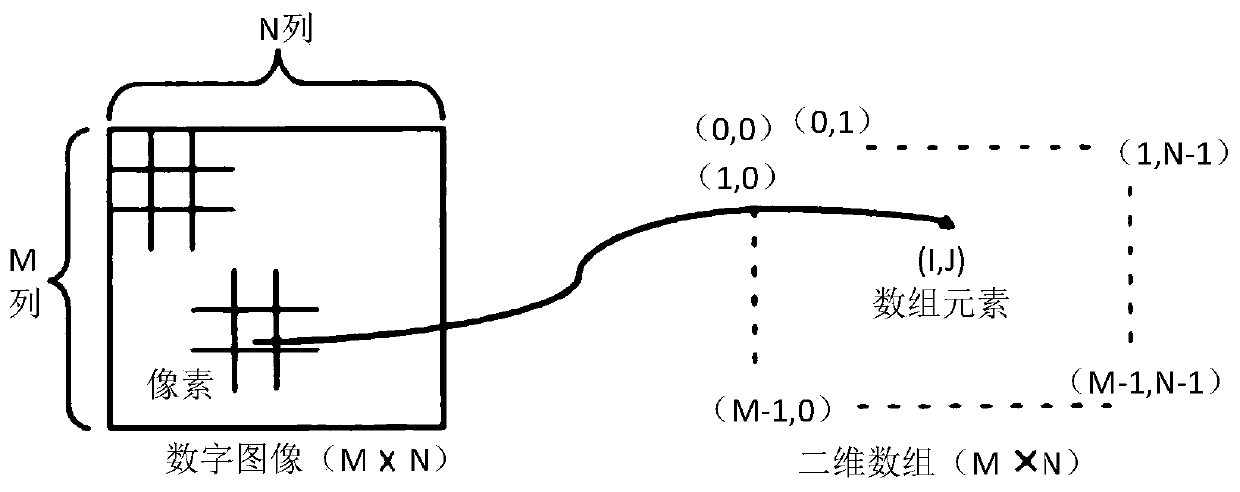

[0049] The image acquisition system mainly includes CCD cameras, LED lights, fixtures, video acquisition cards and computers. figure 2 The schematic diagram of the crack ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap