Turbine small shaft bending vibration and torsional vibration parallel measurement method based on overspeed protection signals

A technology of overspeed protection and measurement method, applied in the directions of linear/angular velocity measurement, velocity/acceleration/shock measurement, measurement device, etc., which can solve the inconvenient installation of sensors, increase the cost of sensors and the measurement channel of detection instruments, and do not design and install bending vibration. and torsional vibration measurement probes, to avoid equipment installation problems and reduce equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In the following, combined with the accompanying drawings and taking the overspeed protection simulation signal of a steam turbine unit as an example, a parallel measurement method for bending and torsional vibration of the small shaft of the machine head based on multiple overspeed protection signals is carried out. The specific implementation process is as follows:

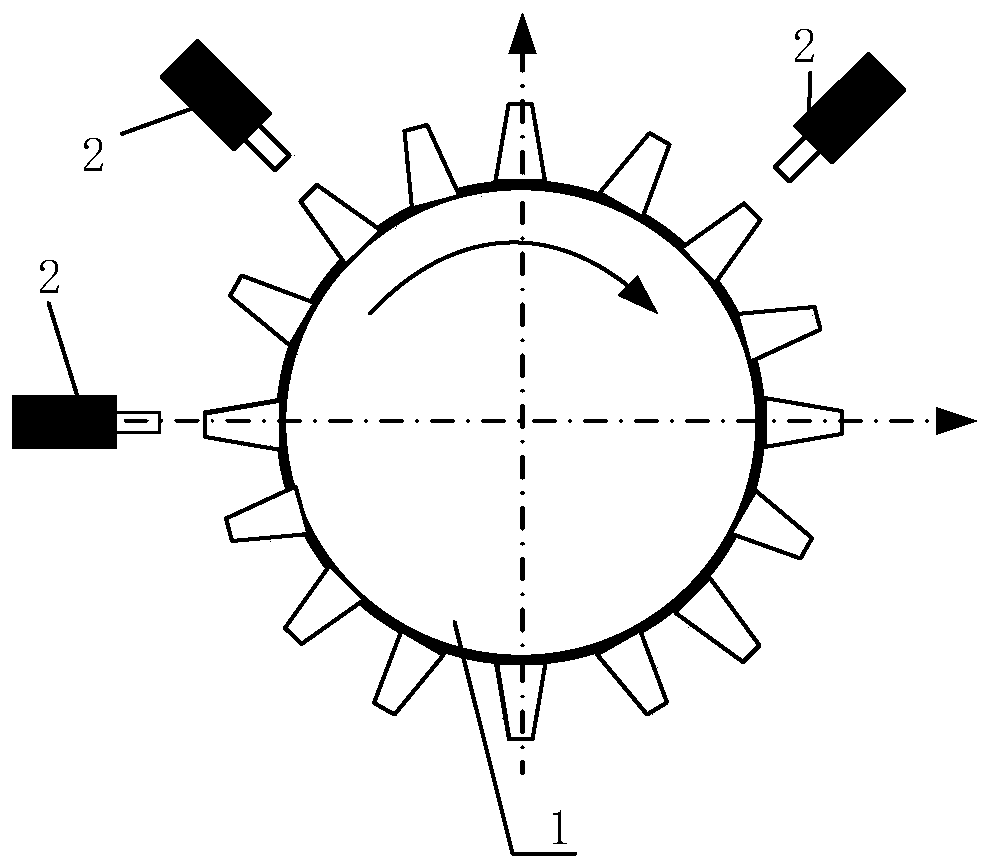

[0042] (1) if figure 1 As shown, the static technical parameters of the existing speed measuring gear device at the small shaft of the steam turbine head are obtained, including the number of teeth of the speed measuring gear plate 1 or the interval number of other equal parts, the radius of the shaft section, the existing eddy current sensor, photoelectric The installation angle of the velocity sensor 2 of the forms such as sensor, magnetoresistive sensor. In this example, the number of teeth of the speed measuring gear is 180 teeth, the radius of the shaft section is 200mm, and the reverse rotation dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com