A group anchor effect model test device and detection method

A model test device and effect technology, which is used in measurement devices, preparation of test samples, instruments, etc., can solve problems such as the inability to accurately simulate the real current situation of field bolts, and achieve the effect of improving test accuracy and accurate group anchor effect coefficients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

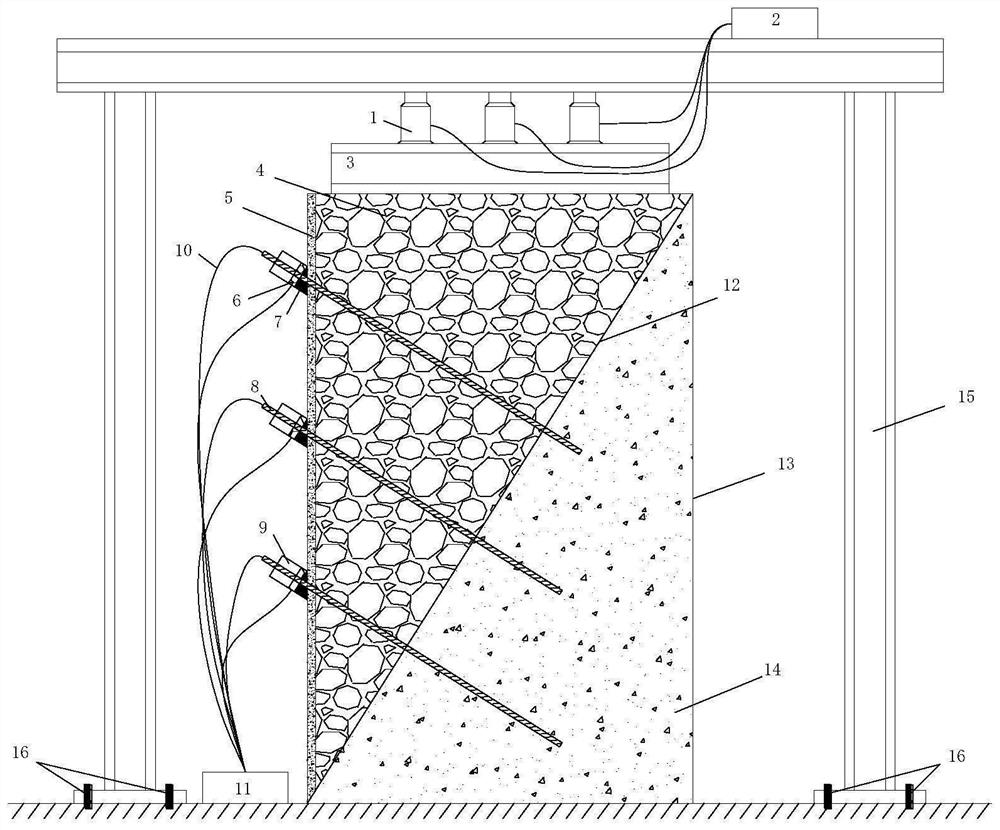

[0024] Such as figure 1 As shown, the present invention includes a model box 13, which facilitates model making and fills simulated formations to form a simulated interface. Model box 13 periphery is provided with reaction force frame 15, and the bottom of reaction force frame 15 both sides is fixed on the ground by anchor bolt 16, makes reaction force frame 15 and ground reliable connection. The reaction frame 15 and the anchor bolts 16 belong to the auxiliary structure of the load loading system, and are mainly used to reliably transmit the loading reaction force of the loading system. The reaction frame 15 can be a steel frame, bent frame or other structures, and only the reaction force The deformation of the frame 15 and the anchor bolts 16 is slight to negligible when the load is applied. The top of the model box 13 is fixed with a load-loading rigid cushion 3, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com