Equipment health index construction and life prediction method based on data fusion network

A technology of health indicators and integrated networks, applied in electrical testing/monitoring, testing/monitoring control systems, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Below in conjunction with accompanying drawing, further describe the present invention through embodiment, but do not limit the scope of the present invention in any way.

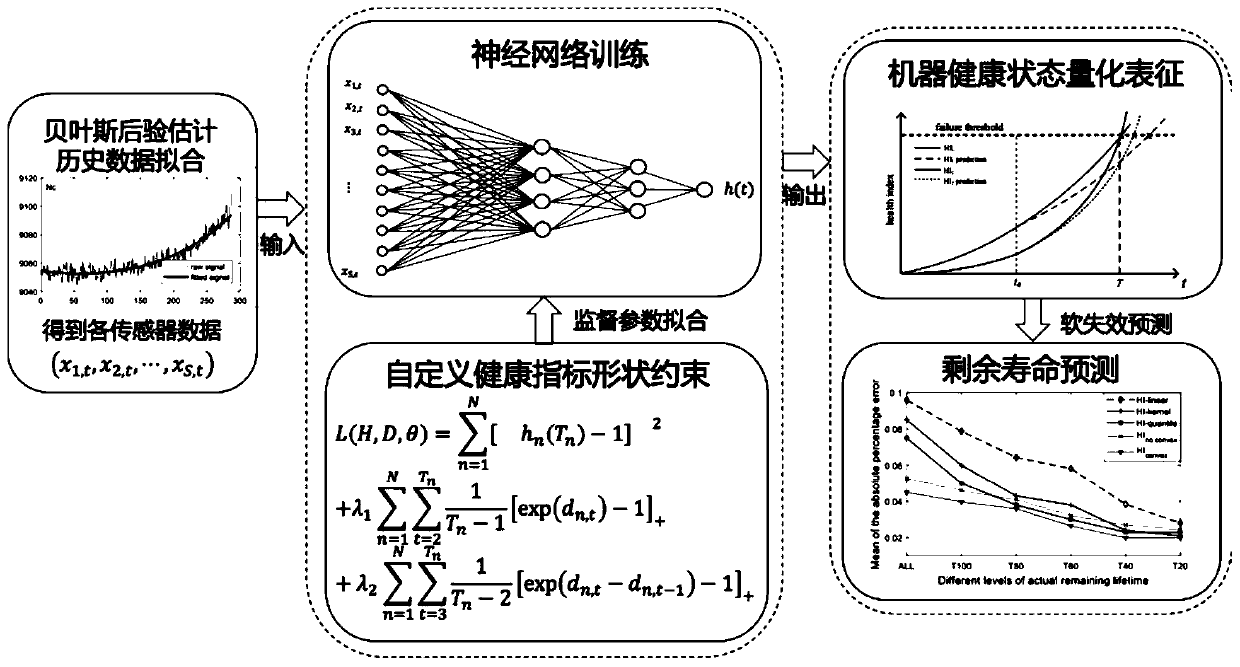

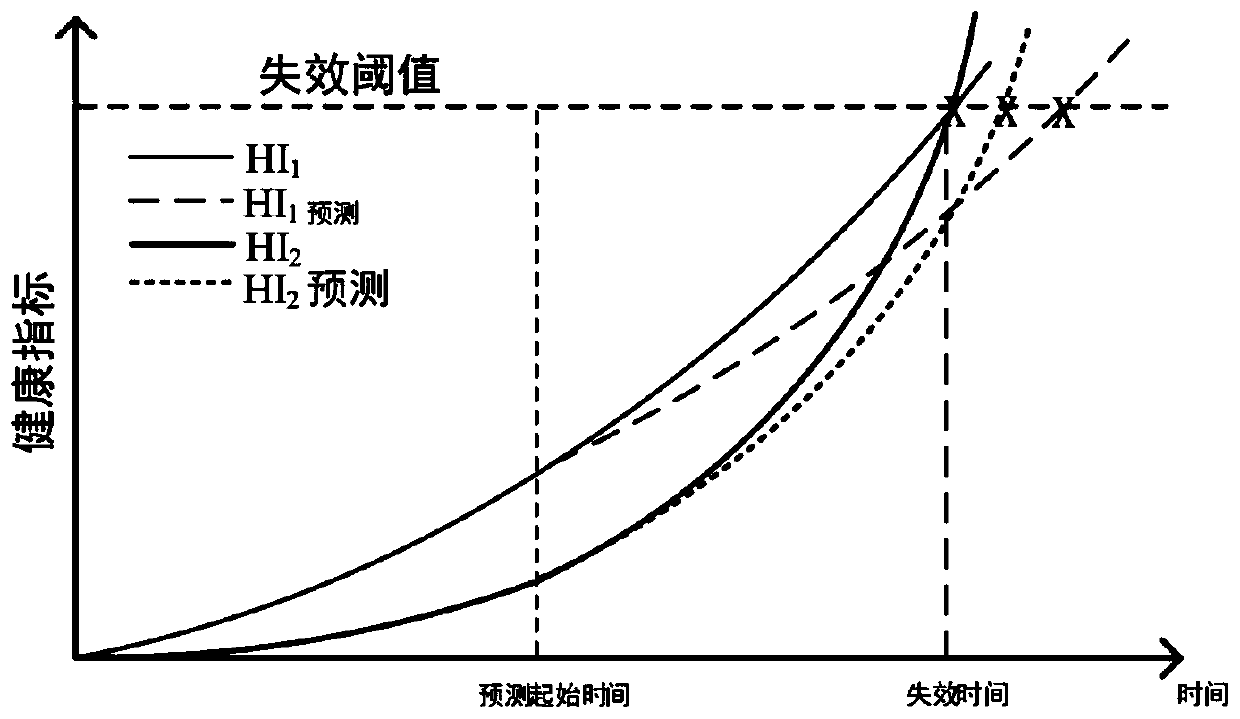

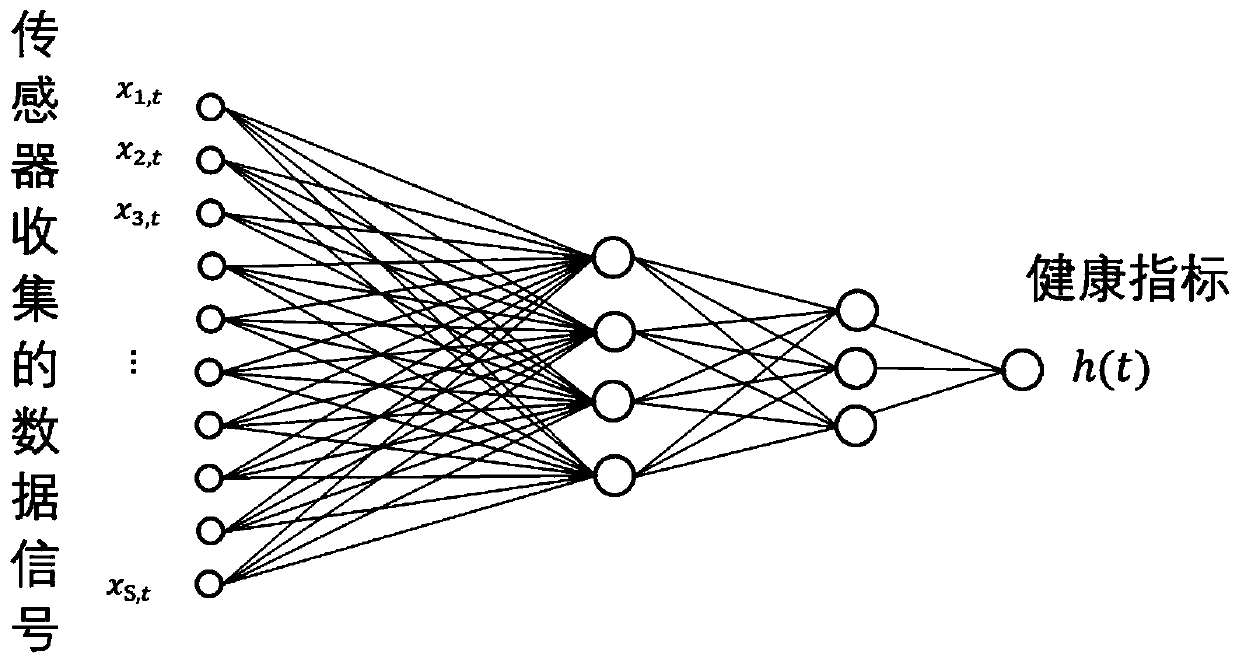

[0068] The invention provides a method for constructing equipment health index and online prediction of remaining life based on Bayesian inference and neural network. The collected sensor signals are fused nonlinearly through the neural network to obtain a comprehensive health status characterization, and based on this health index, the Bayesian inference method is used to predict the remaining service life of the machine. figure 1 Schematic flow chart of the model method provided by the present invention.

[0069] The method of the invention mainly includes two stages, constructing the health index by using the collected sensor data signals of the equipment; and predicting the remaining service life of the machine equipment by using the constructed health index. The present invention specifically c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com