A kind of elastomer with flexible region constructed by hydrogen bond and preparation method thereof

An elastomer and flexible technology, which is applied in the field of flexible polymer elastomer preparation, can solve the problems of poor elastic properties, weak strength, and poor mechanical properties, and achieve improved mechanical strength, increased elastic properties, and good repeated recovery and recycling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0189] The preparation method of the elastic body with the flexible region constructed by hydrogen bonds, the polymer P and the polymer Q are respectively dissolved and mixed at a temperature of 40 to 50 ° C, and after mixing evenly, they are poured into a polytetrafluoroethylene mold, or coated on polytetrafluoroethylene. On the vinyl fluoride plate, the solvent is removed to obtain an elastomer with a flexible region constructed by hydrogen bonds;

[0190] The solvent used for dissolving is N,N dimethylformamide (DMF), N,N dimethylacetamide (DMAC), dimethyl sulfoxide (DMSO) or nitrogen methylpyrrolidone (NMP);

[0191] The dissolved concentration is between 5% and 20% by weight;

[0192] The solvent removal refers to volatilizing most of the solvents in an environment of 40-50° C., and finally drying thoroughly.

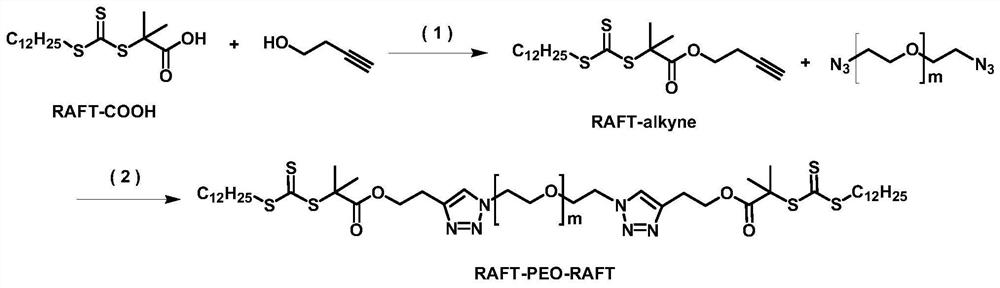

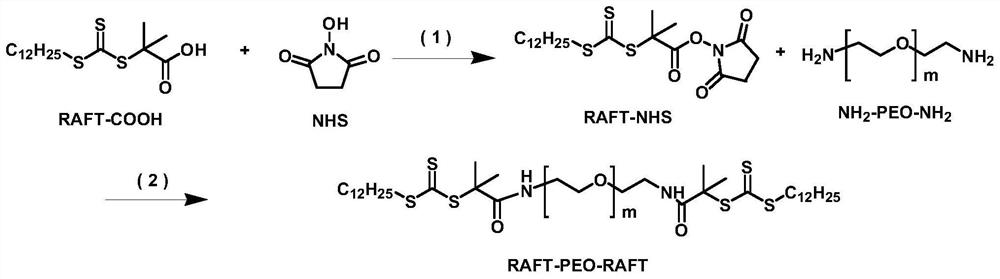

[0193] When A in the polymer P is PEO, the preparation steps of the polymer P are as follows:

[0194] (1) Prepare macromolecular chain transfer reagent RAFT-PEO...

Embodiment 1

[0224] Method for constructing elastomers from triblock polymer polystyrene-polyacrylic acid-polystyrene (PS-PAA-PS) and homopolymer polyethylene oxide PEO:

[0225] The molecular weight of PAA is Mn=78000, the molecular weight of PEO is Mn=40000, and the mass fraction of PS accounts for 15wt% of PS-PEO-PS / PAA;

[0226] Dissolve PS-PEO-PS and PAA respectively in the solvent DMF (the dissolved concentration is 5wt%) and mix them at a temperature of 40°C. After mixing evenly, pour them into a polytetrafluoroethylene mold, and volatilize all Solvent, an elastomer with flexible regions constructed by hydrogen bonds is obtained.

[0227] The strength of the elastic body constructed by the hydrogen bond to construct the flexible region is 6MPa under the environment of 40% humidity, the elongation at break is 600%, and the elastic recovery rate is 91%. It has humidity responsiveness (as the humidity increases, the softer) and pH responsiveness.

Embodiment 2

[0229] Method for constructing elastomers from triblock polymer polystyrene-polyethylene oxide-polystyrene (PS-PEO-PS) and homopolymer polyacrylic acid PAA:

[0230] The molecular weight of PEO is Mn=70000, the molecular weight of PAA is Mn=84000, and the mass fraction of PS accounts for 20wt% of PS-PAA-PS / PEO;

[0231] Dissolve PS-PAA-PS and PEO respectively in the solvent DMF (the dissolved concentration is 10wt%) and mix them at a temperature of 45°C. After mixing evenly, inject them into a polytetrafluoroethylene mold, and volatilize at 50°C Solvent, and finally completely dried to obtain an elastomer with a flexible region constructed by hydrogen bonds.

[0232] The strength of the elastic body constructed by the hydrogen bond to construct the flexible region is 6MPa under the environment of 60% humidity, the elongation at break is 600%, and the elastic recovery rate is 93%. It has humidity responsiveness (as the humidity increases, the softer) and pH responsiveness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com