Pulping machine millstone, pulping machine, rotor and pulping machine

A technology of refiner and grinding disc, which is applied in pulp beating/refining method, textile and papermaking, fiber raw material processing, etc. It can solve the problems of reducing binding capacity, etc., and achieve reduced cutting, high fiber-to-fiber binding capacity, and effective energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

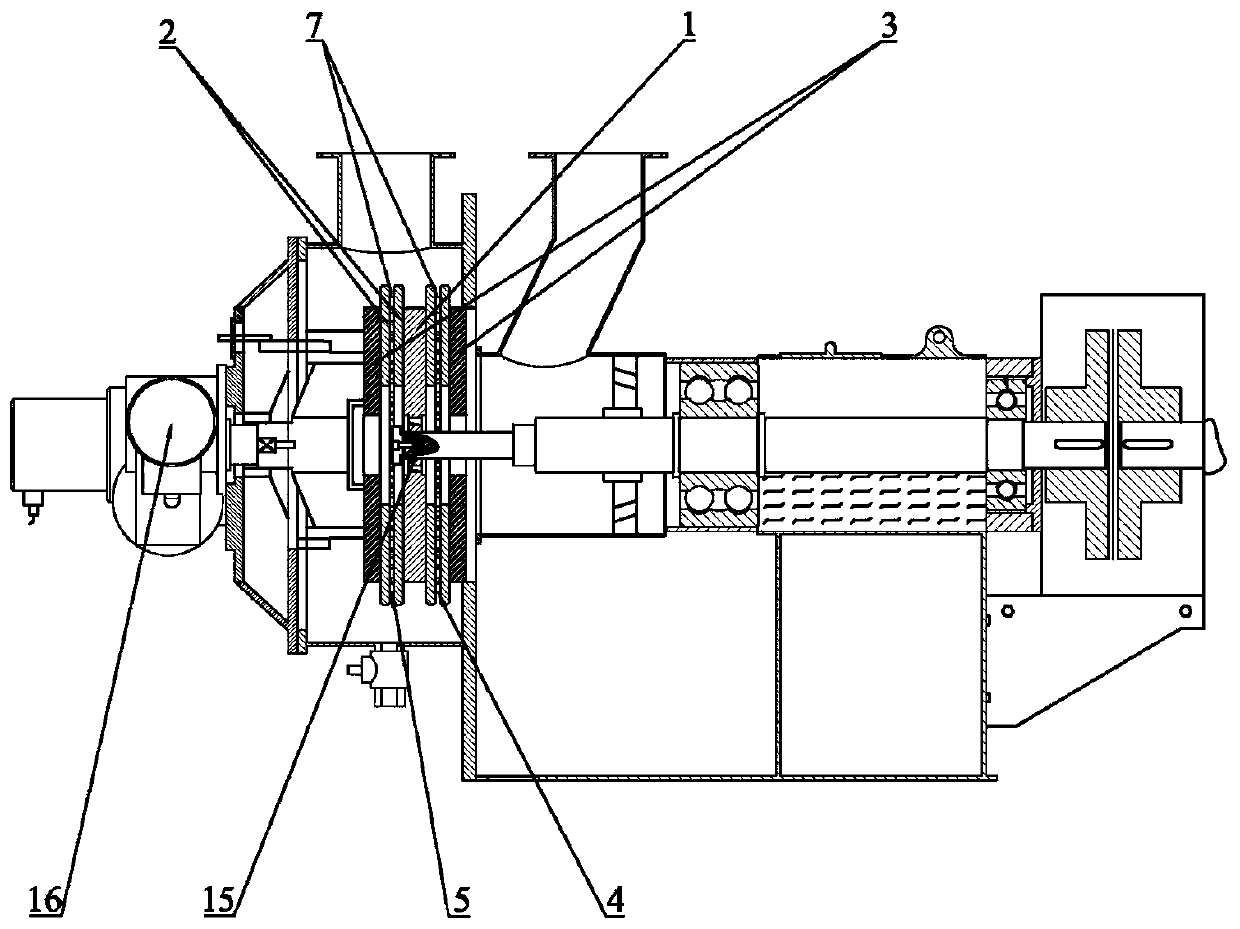

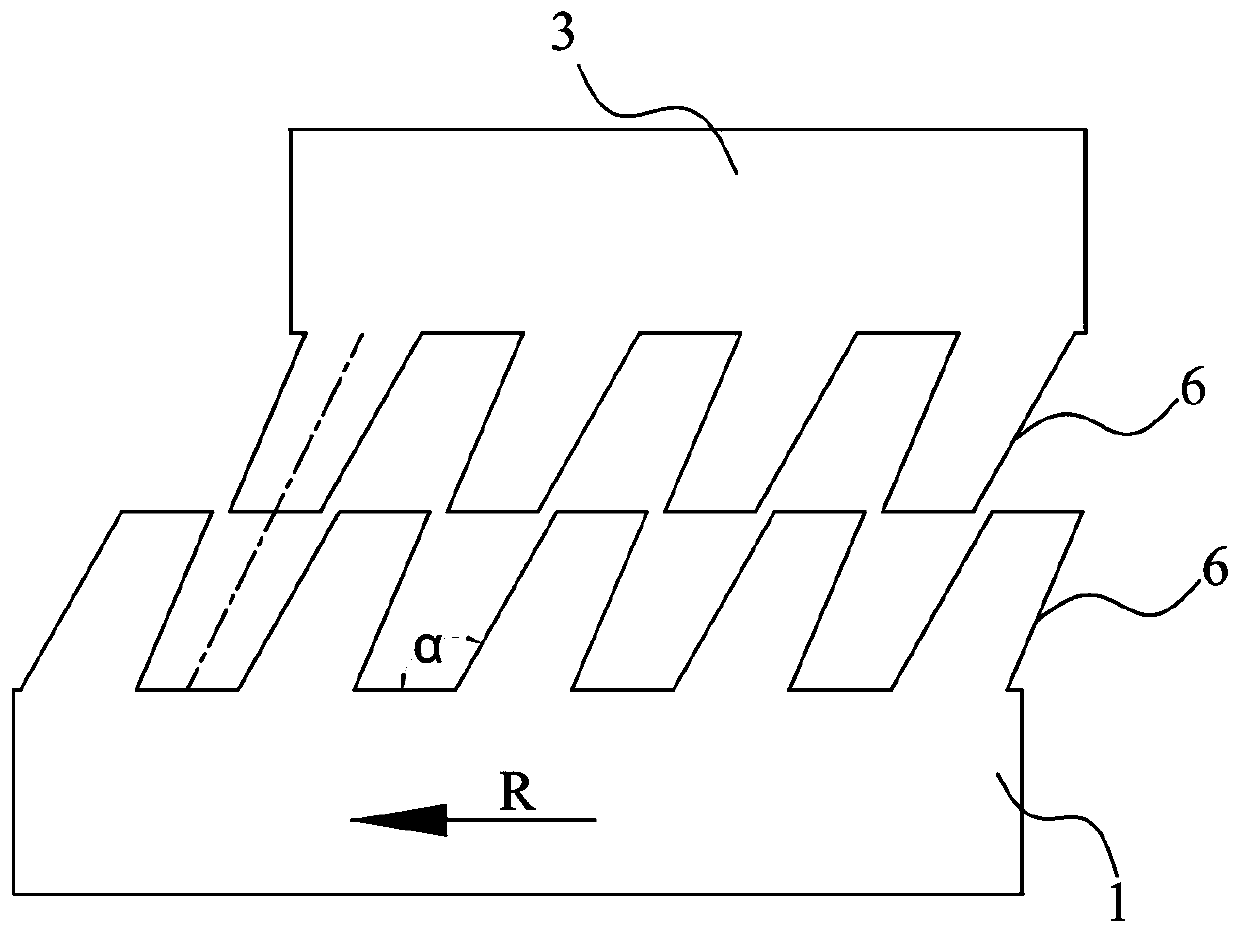

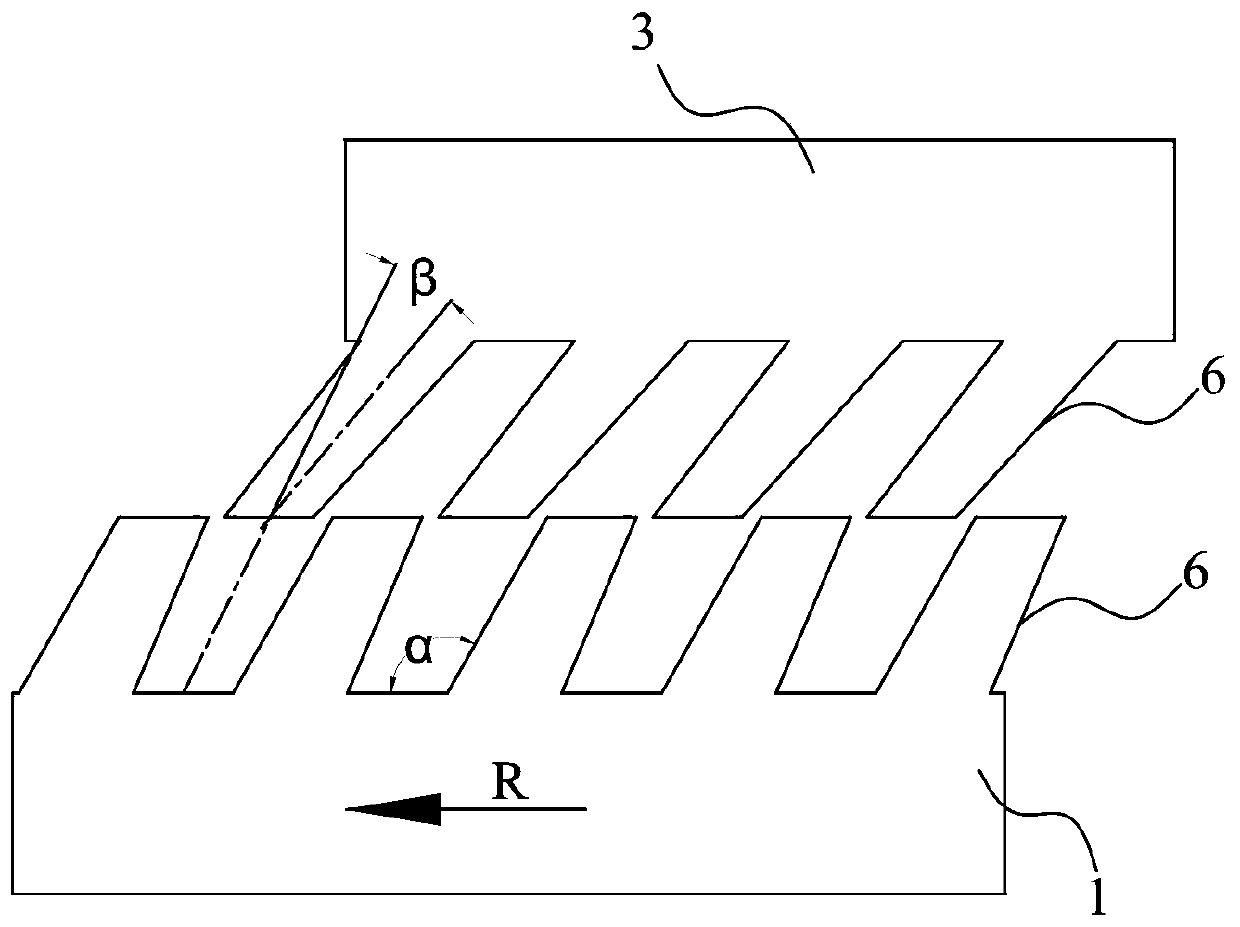

[0027] figure 1 The main configuration of the double disc refiner is schematically shown. Its refiner rotor comprises: rotor main body 1, and described rotor main body 1 has the drive motor side 4 facing the drive motor when installed and the gap adjustment side 5 facing away from the drive motor (refiner door side, gap adjustment device 16 is installed ), both sides of the rotor main body 1 are arranged with grinding discs 2 with several sharpening blades 6; two stators, the rotor main body 1 is designed to be suitable for rotating between these two stators 3, wherein, Each of the stators 3 is provided with a grinding disc 2 with a sharpening edge 6 on the side facing the rotor main body 1, whereby the rotor main body 1 on the drive motor side 4 and the gap adjustment side 5 are respectively The main body 1 and the corresponding stator 3 form a refining zone 7 ; wherein the rotor main body 1 is designed to be adapted to be floatingly connected with a central area on a rotati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap