Method for designing sole model of sole heel area buffer structure

A buffer structure and model design technology, applied in design optimization/simulation, CAD numerical modeling, etc., can solve the problems of high cost and low efficiency, and achieve the effect of cost saving and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below through specific embodiments.

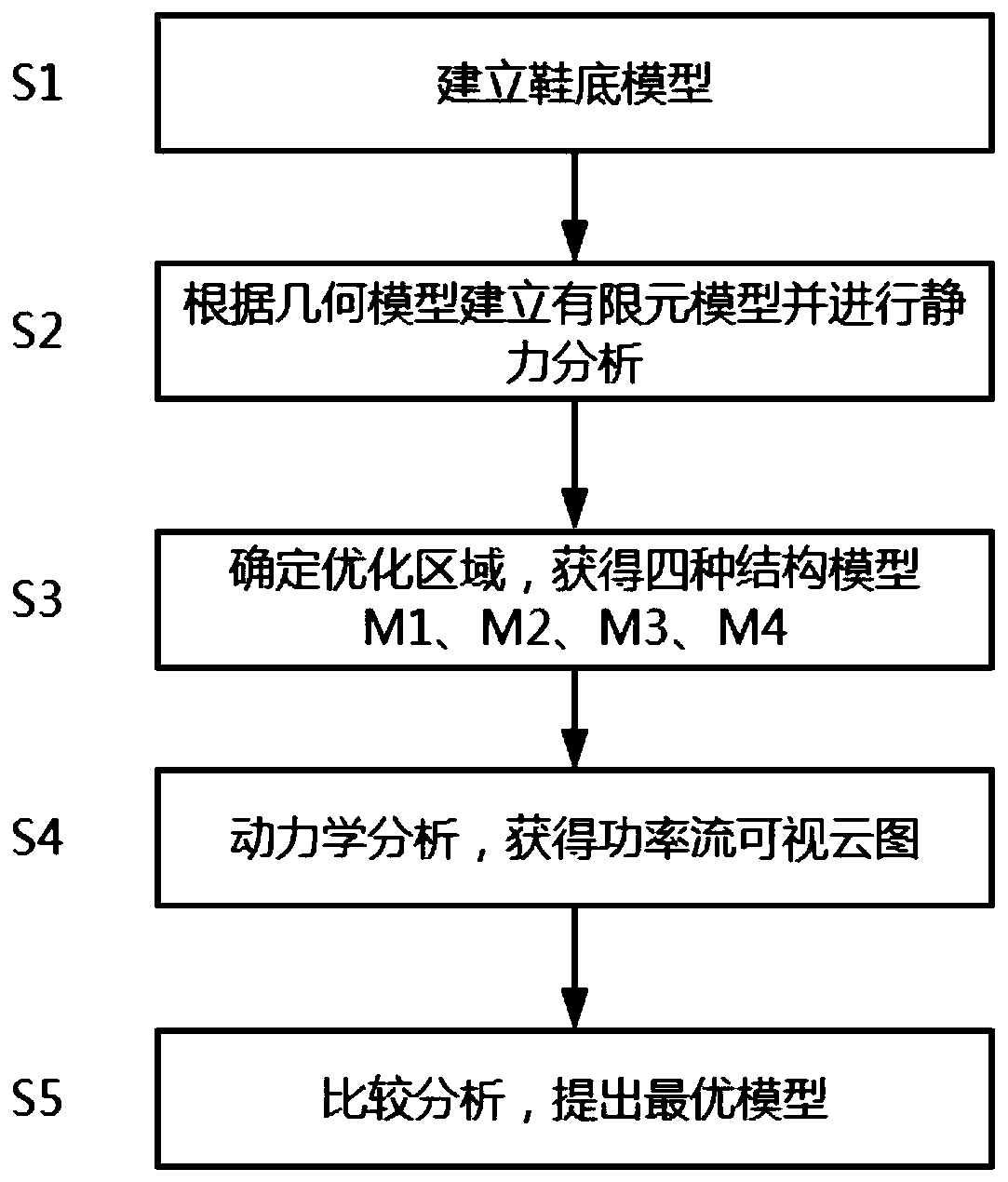

[0048] A kind of sole model design method of heel region cushioning structure, such as figure 1 and figure 2 shown, including:

[0049] Step S1: Establish the sole model before optimization in UG.

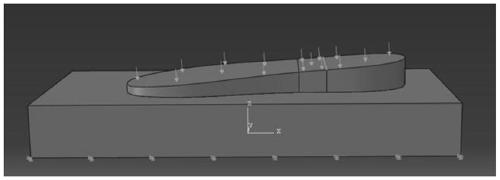

[0050] Step S2: Establish the finite element model of the sole model in step S1 and perform static analysis, such as image 3 shown, including:

[0051] Step S21: Import the sole model and bottom surface model into abaqus. Abaqus is a set of powerful finite element software for engineering simulation, including a rich cell library that can simulate arbitrary geometric shapes, and has various types of material model libraries, which can simulate the performance of typical engineering materials.

[0052] Step S22: Assign material properties to the sole model and the ground model respectively, wherein the material properties include mass density, Young's modulus and Poisson's ratio, so ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap