Extra High Voltage DC Power Cable

A power cable and ultra-high voltage technology, applied in the field of ultra-high voltage DC power cables, can solve the problems of accumulated space charge and electric field distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

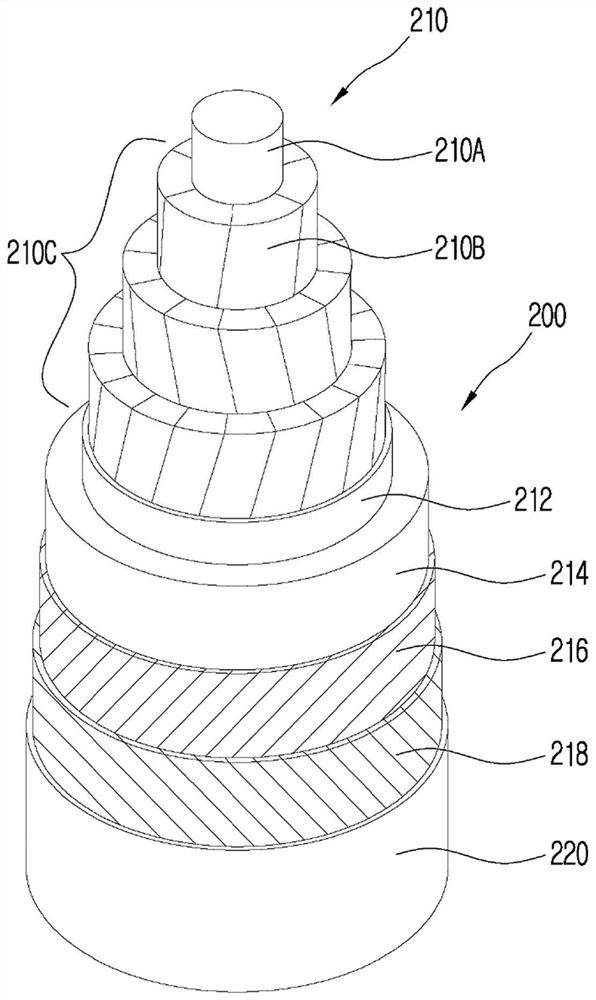

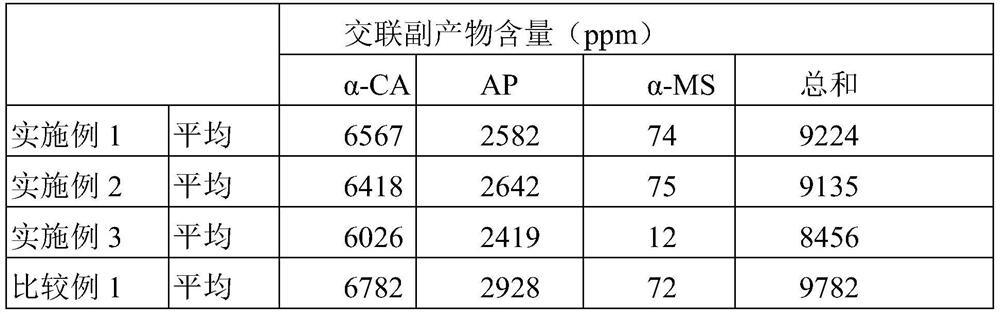

[0074] As a cable including an inner semiconductive layer, an insulating layer, and an outer semiconductive layer, by adjusting the content of a crosslinking agent and the content of inorganic particles added to the insulating layer, and by adjusting crosslinking by-products by crosslinking and degassing Thus, the average value of each layer of the content of the cross-linked by-products of the cross-linked by-products of the inner layer, the middle layer and the outer layer that is divided into three equal parts by the thickness of the insulating layer is produced and adjusted as The cables of the embodiment and comparative example shown in Table 1. The content of the cross-linked by-products is measured by extracting a test piece at an arbitrary position in the middle of each layer.

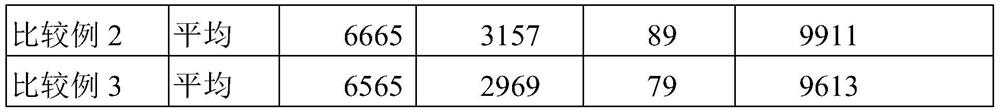

[0075] 【Table 1】

[0076]

[0077]

[0078] Volume resistance evaluation

[0079] After extracting an insulation test piece with a thickness of about 170um from the insulation layer of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com