Worm wheel type ratchet wheel type hoisting mechanism

A technology of hoisting mechanism and worm gear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

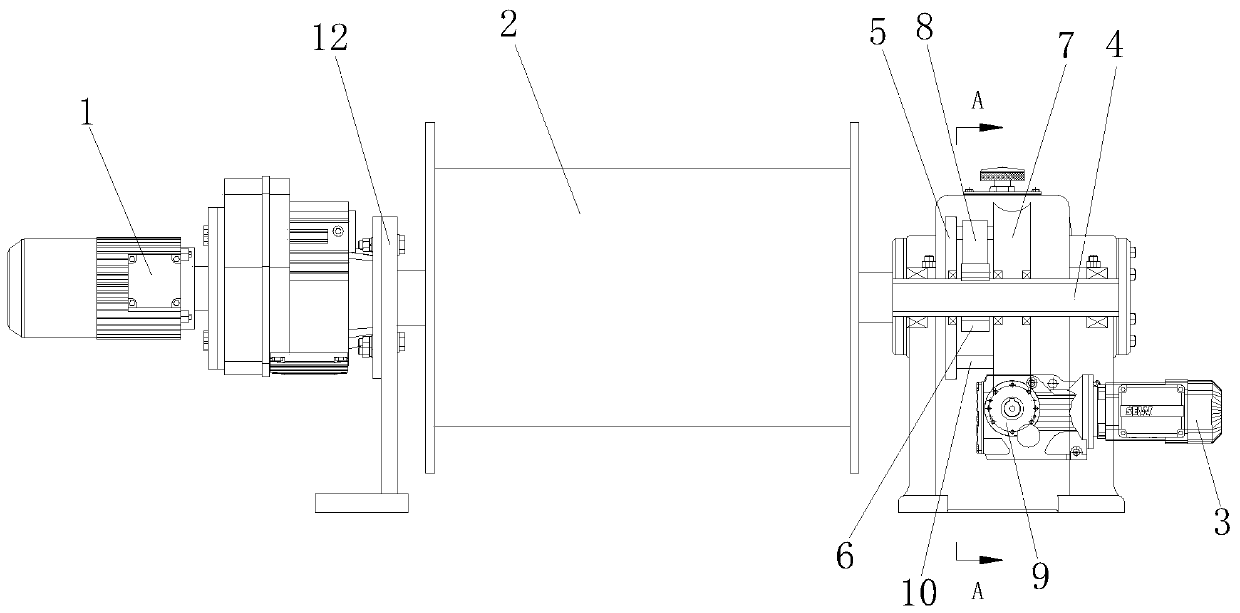

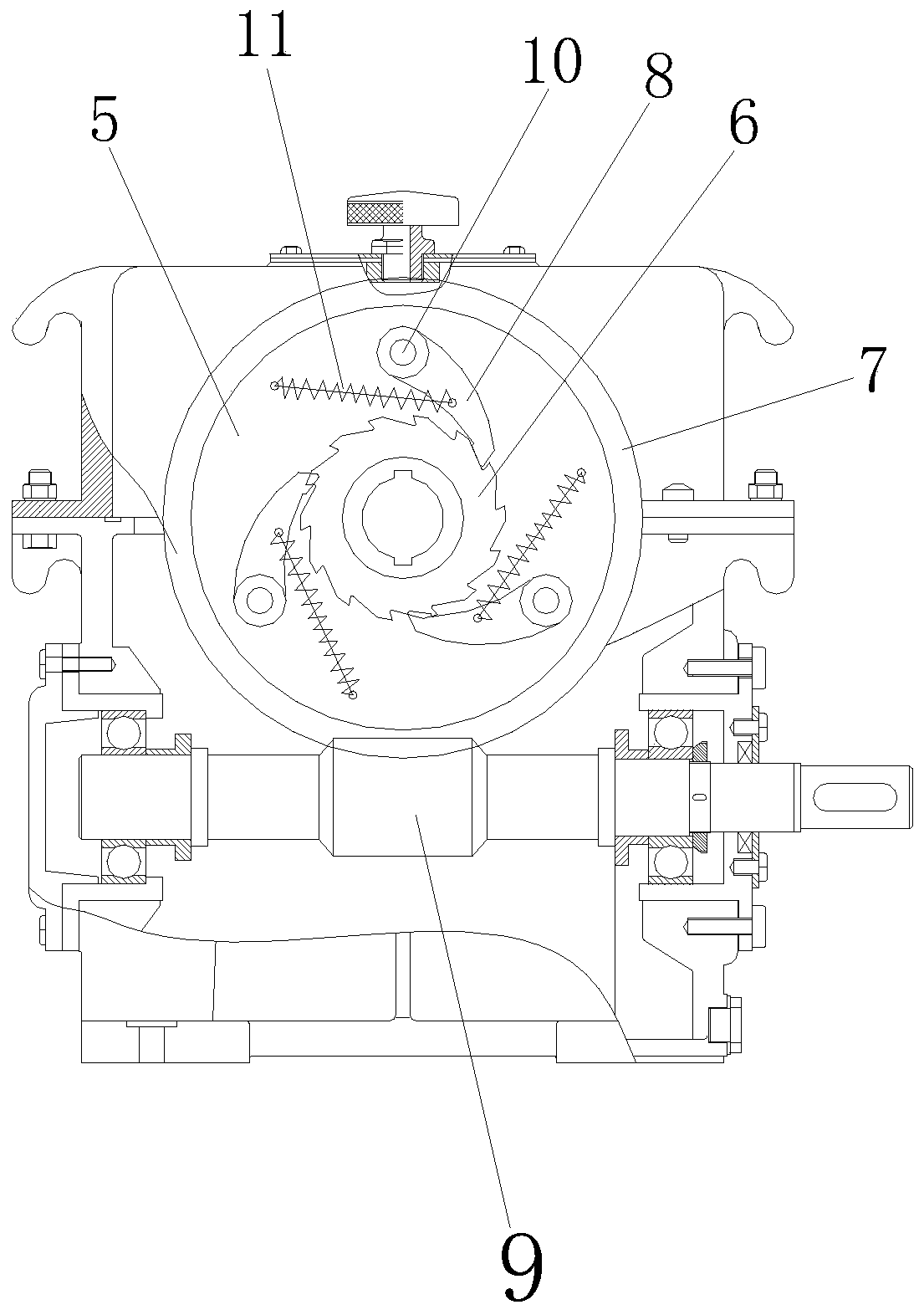

[0011] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0012] As shown in the figure, the worm-wheel-type ratchet-type hoisting mechanism of the present invention is provided, including a motor and a reel 2, and it also includes a pawl-type worm gear and worm one-way power transmission reduction mechanism, and the motor includes a lifting motor 1 and a falling motor 3, The ratchet type worm gear one-way power transmission speed reduction mechanism includes an output shaft 4, a centering disc 5, a ratchet 6, a worm wheel 7, a pawl 8, and a worm 9, and the ratchet 6 is fixed on the output shaft 4 and rotates with the output shaft 4 , the centering disc 5 and the worm wheel 7 are sleeved on the output shaft 4 through bearings but do not rotate with the output shaft 4, the centering disc 5 is located on the left side of the ratchet 6, the worm wheel 7 is located on the right side of the ratchet 6, and one end of the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com