Combined cylinder cover with built-in separated gasket sleeve

A technology of gaskets and gaskets, which is applied in the field of hydraulic cylinders and can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

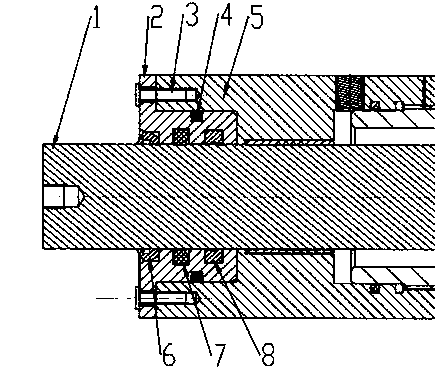

[0015] Below in conjunction with accompanying drawing illustrate specific embodiment, as figure 1 Said, the combined cylinder head with built-in split gasket cover includes a cylinder cover (5) and a gasket cover (2), and it is characterized in that a gasket cover groove is opened at one end of the cylinder cover (5). The gasket cover (2) is installed in the gasket cover groove and connected by screws (3).

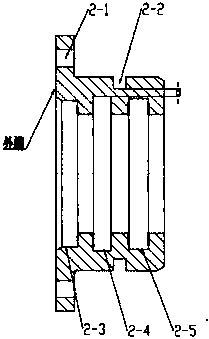

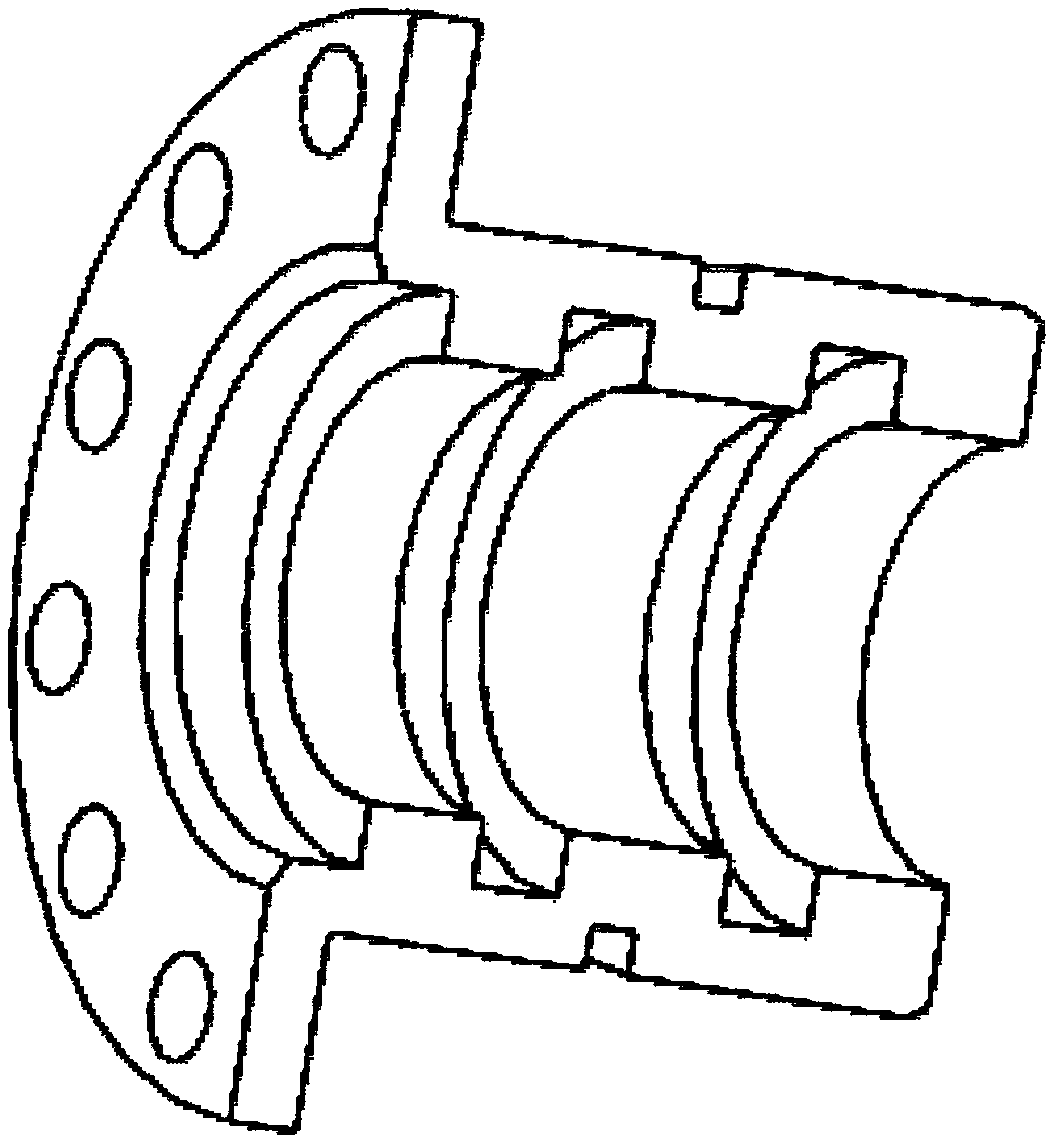

[0016] Such as figure 2 , Shown in 3, said is characterized in that the gasket sleeve (2) is a split structure, which is composed of two symmetrical gasket sleeves (2).

[0017] Such as figure 2 As shown, the sizes, tolerances, and surface roughness of all the grooves provided by the two symmetrical gasket sets (2) are exactly the same, and the inner side of the gasket sets (2) is sequentially provided with dust ring grooves (2-3), The first sealing ring groove (2-4), the second sealing ring groove (2-5), and the dustproof ring groove (2-3) are opened at the outer end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com