Worm and gear type detection probe carrying device and oil pipe field electromagnetic flaw detection method

A technology for detecting probes, worm gears and worms, applied in the direction of material magnetic variables, etc., can solve the problem of inability to detect vertical oil pipe flaws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

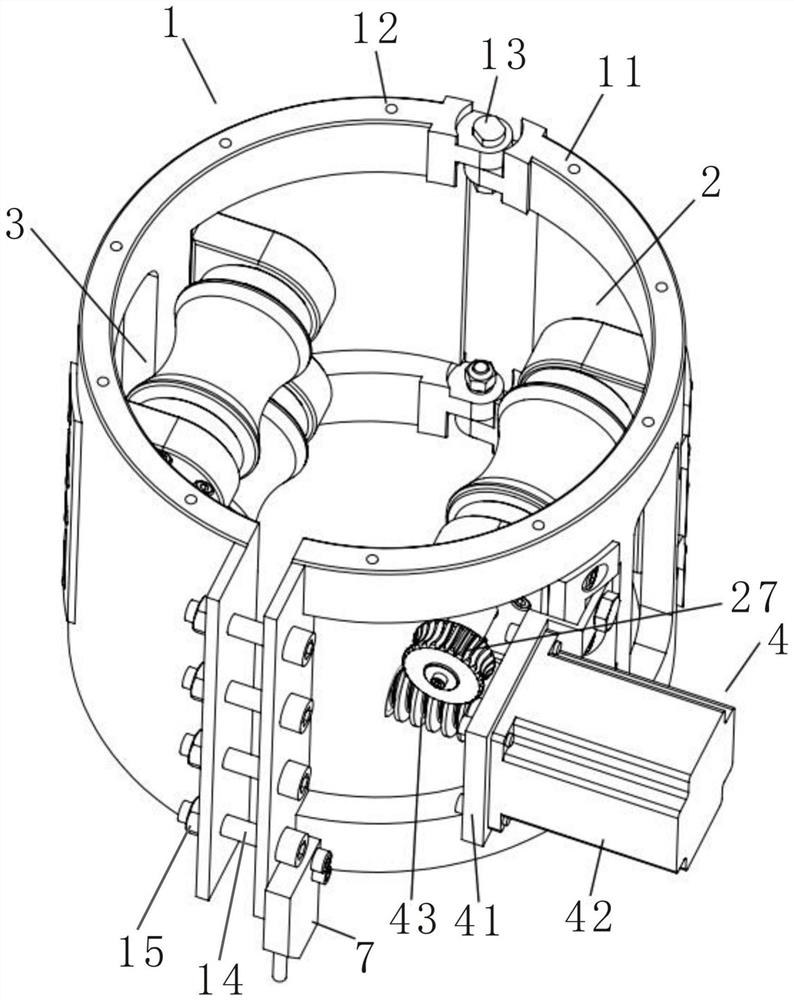

[0044] like Figure 1-4 As shown, the embodiment of the present invention discloses a worm gear type detection probe carrying device, which is sleeved on the oil pipe 5 placed vertically on site, and includes: a frame 1, a driving wheel mechanism 2, a driven wheel mechanism 3 and a power mechanism 4;

[0045] The frame 1 is a semi-open structure, which is composed of a first semi-cylindrical frame structure 11 and a second semi-cylindrical frame structure 12 to form a whole cylindrical frame structure; an electromagnetic flaw detection probe 6 is installed on the outer upper end of the frame 1;

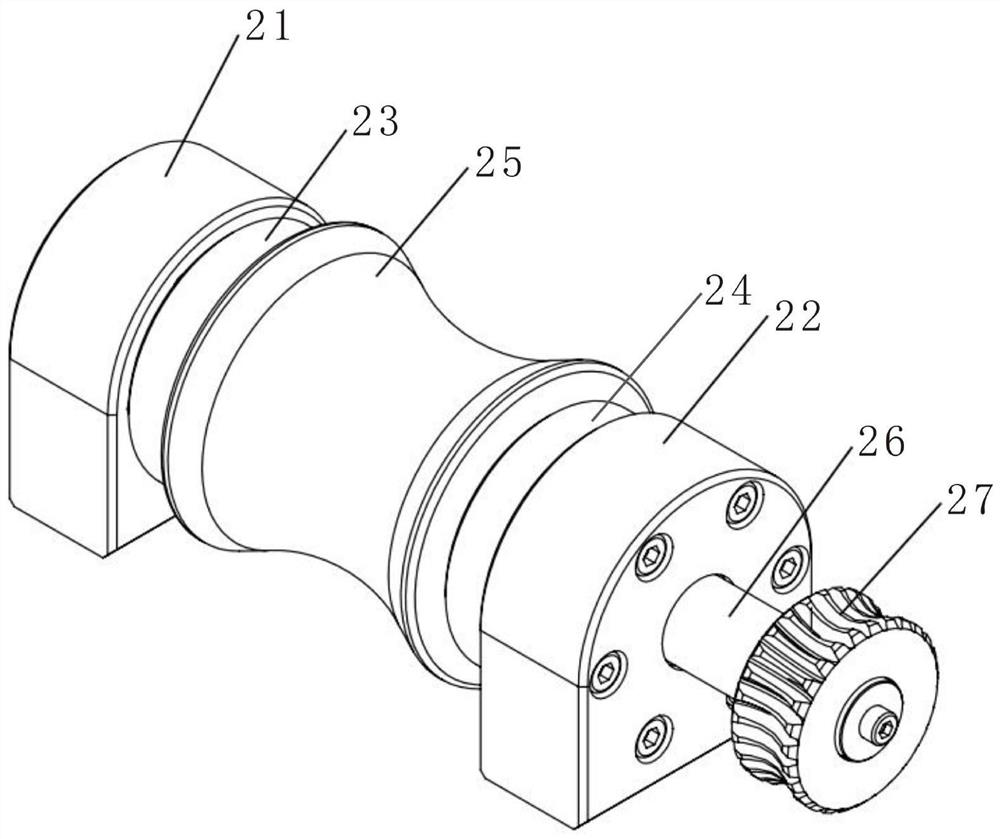

[0046] The driving wheel mechanism 2 comprises a first driving wheel support seat 21, a second driving wheel support seat 22, a first driving wheel end cover 23, a second driving wheel end cover 24, a driving wheel roller 25, a driving wheel shaft 26 and a worm wheel 27, the driving wheel The axial direction of the wheel shaft 26 is horizontal and one end of the driving wheel shaft 2...

Embodiment 2

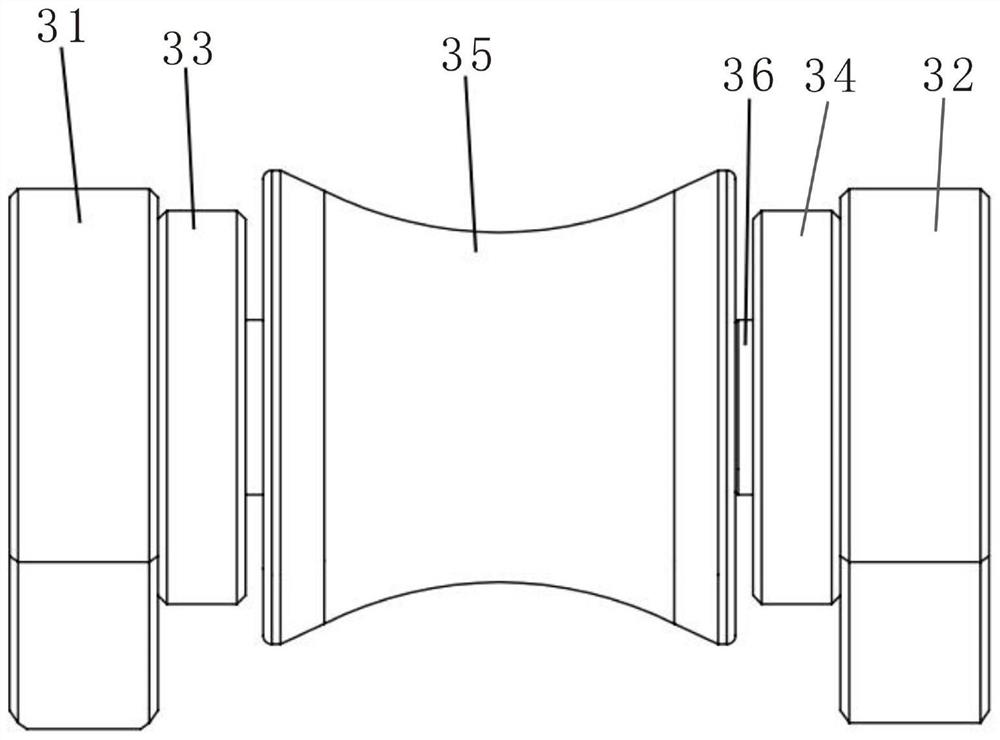

[0058] The structure of the worm gear type detection probe carrying device in this embodiment is basically the same as that in Embodiment 1, the difference is that there are three driven wheel mechanisms 3 in this embodiment, including a main driven wheel mechanism and a set of auxiliary Passive wheel mechanisms, such as figure 1 As shown, the main driven wheel mechanism is opposite to the position of the driving wheel mechanism 2 in the frame 1, and the remaining auxiliary driven wheel mechanisms are installed in pairs on the first semi-cylindrical frame structure 11 and the second semi-cylindrical frame structure 12, and are aligned with the main The installation positions of the passive wheel mechanism and the driving wheel mechanism 2 correspond up and down and have a certain distance.

[0059] On the basis of the above technical solution, multiple sets of auxiliary driven wheel mechanisms can also be provided, and the installation positions of each set of auxiliary driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com