Pre-charging circuit fault detection method and device

A pre-charging circuit, fault detection technology, applied in battery circuit devices, circuit devices, electronic circuit testing and other directions, can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Note that the aspects described below in conjunction with the drawings and specific embodiments are only exemplary, and should not be construed as limiting the protection scope of the present invention.

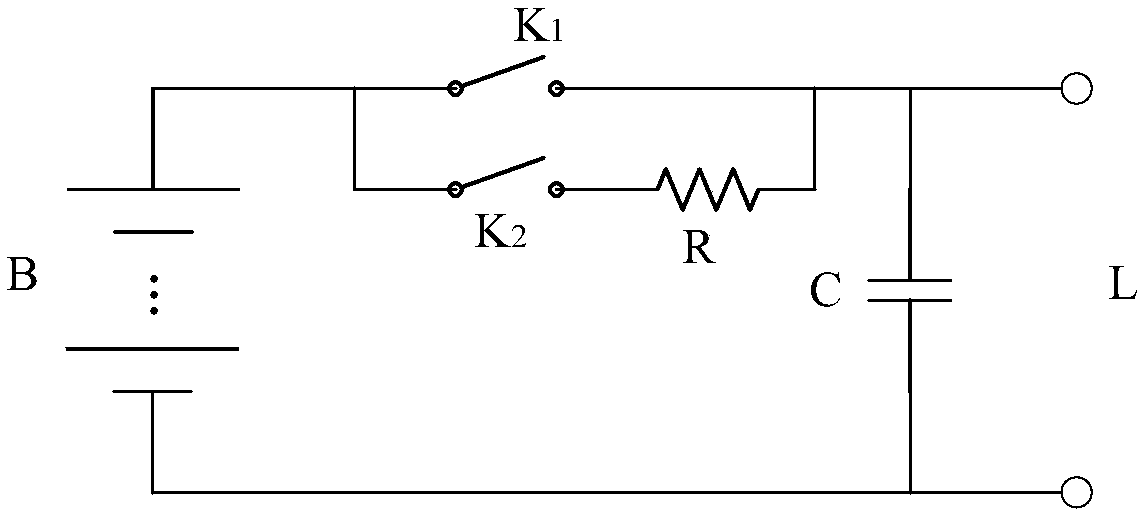

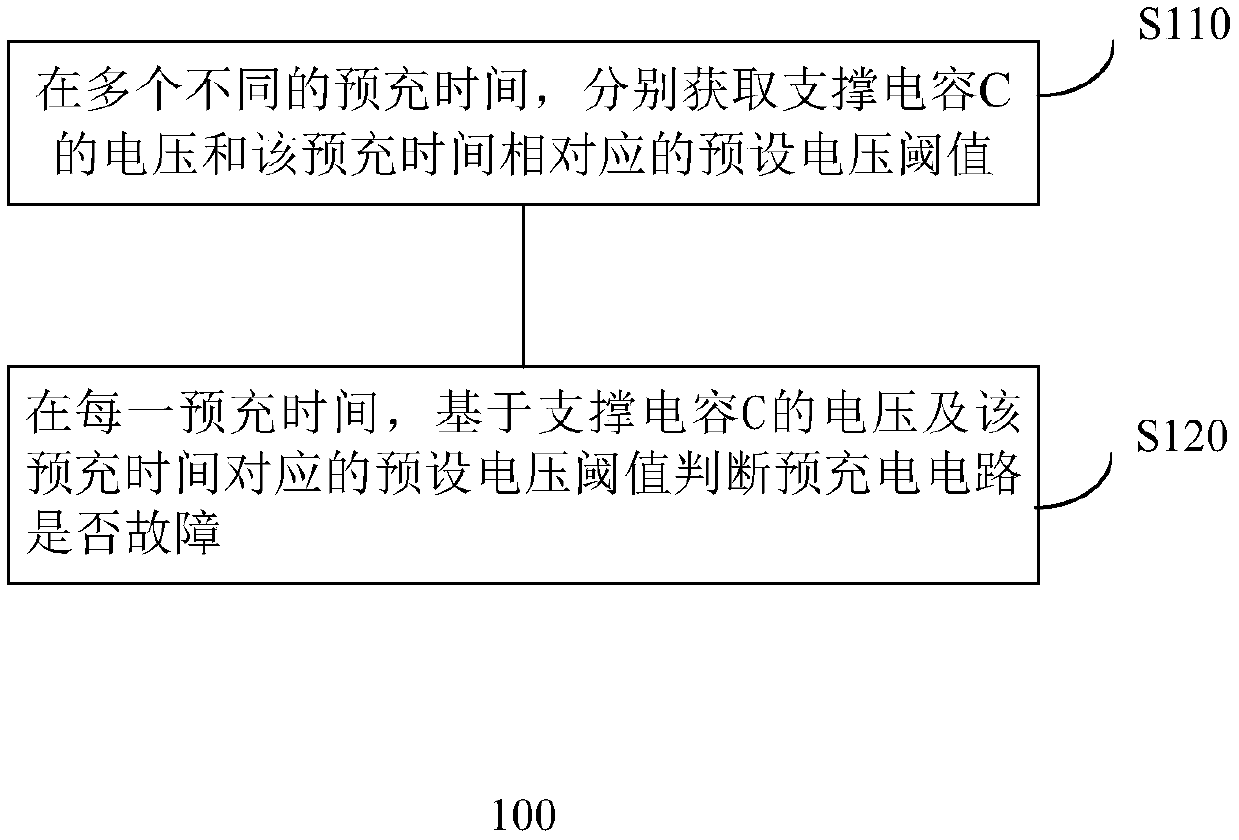

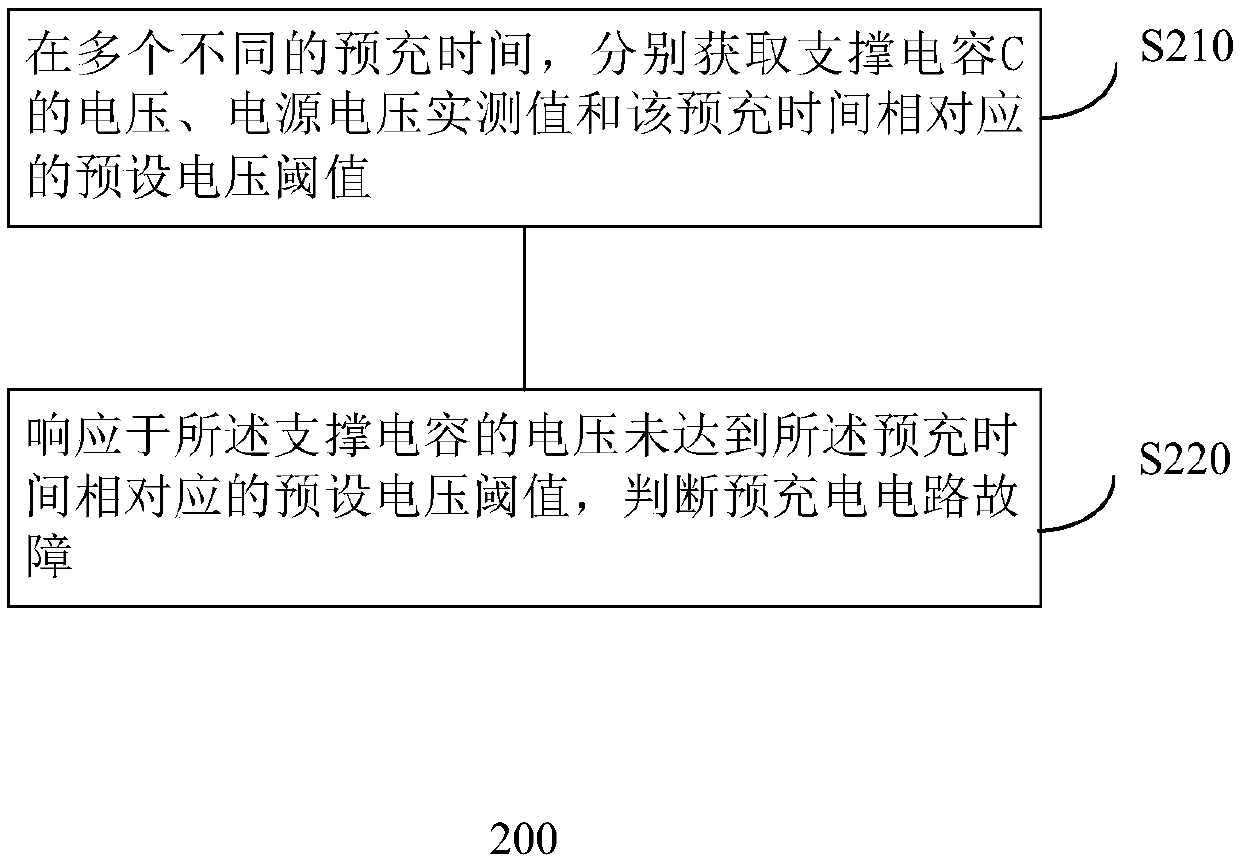

[0047] Because in the prior art, it is only possible to judge whether the charging process is completed by judging whether the voltage of the supporting capacitor is equal to the power supply voltage when the pre-charging time reaches the time required for the pre-charging circuit to complete the pre-charging process, and at the same time, if the supporting If the voltage of the capacitor is not equal to the power supply voltage, it can be judged that the pre-charging circuit may be faulty, but it cannot be judged whether the pre-charging circuit is faulty during the pre-charging process. Therefore, according to one aspect of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com