Multidisciplinary Optimal Design Method for Suspension System Based on Brake Judder and Road Noise Performance

A suspension system and optimization design technology, applied in multi-objective optimization, design optimization/simulation, computer-aided design, etc., to achieve the effects of reducing the risk of design changes, low cost, and saving R&D costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

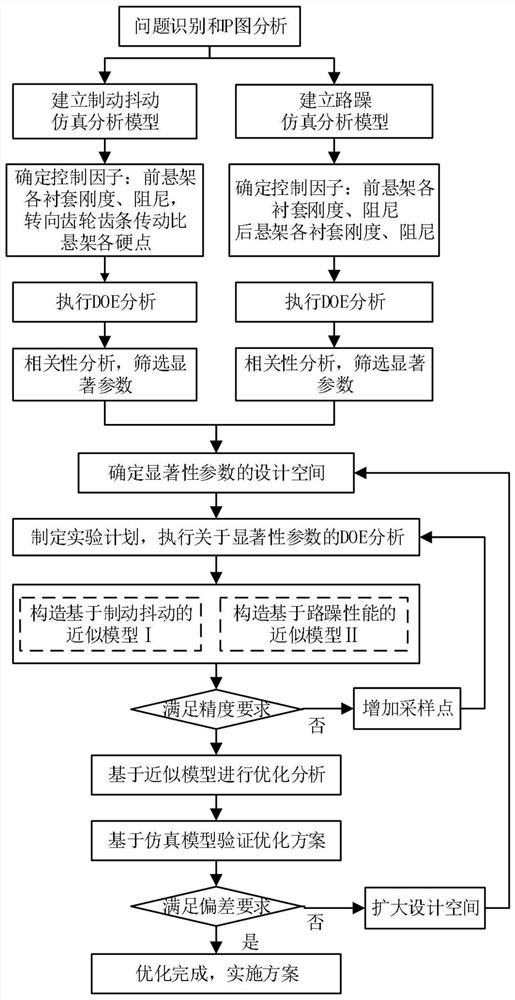

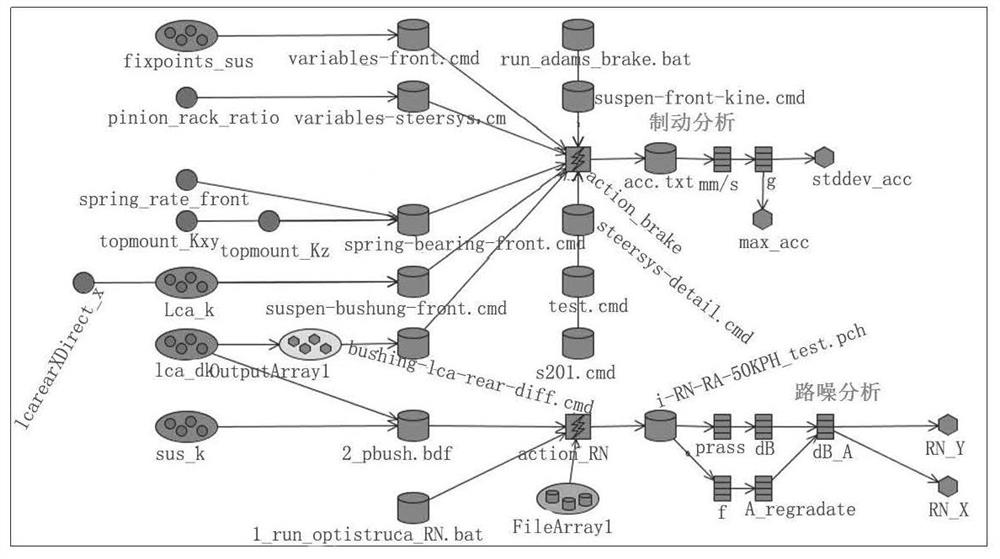

[0031] Such as figure 1 A suspension system multidisciplinary optimization design method based on brake vibration and road noise performance is shown, including the following steps: Step 1, problem identification and P-diagram analysis, to determine the relevant parameters of the suspension system multidisciplinary optimization design;

[0032] There are many factors that affect the performance of brake vibration and road noise, such as: time influence, external ambient temperature, interaction between various systems of the vehicle (suspension system change, tire pressure change), system error (hard point size error, etc. ) and user usage. Through the analysis of the P diagram, the relevant parameters of the multidisciplinary optimal design of the suspension system are determined as follows:

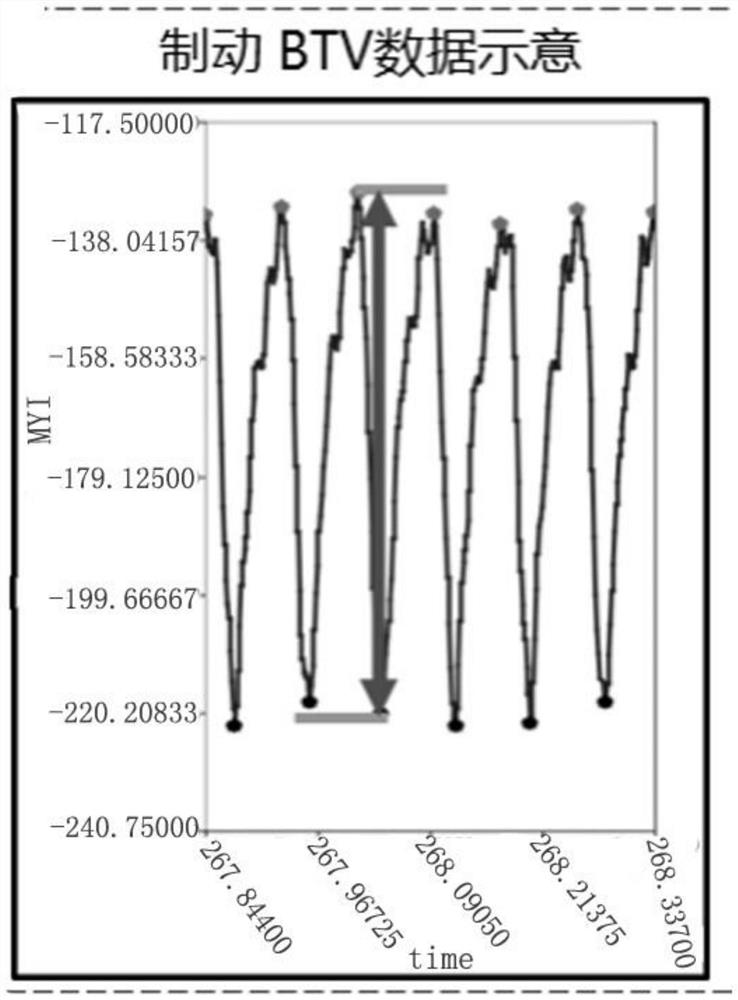

[0033] The input signal includes the BTV data of the brake disc under the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com