Fire protection cart

A cart and fire-fighting technology, applied in fire rescue and other fields, can solve problems such as loss of control of electromagnetic response, failure to find fire source in time, deflagration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

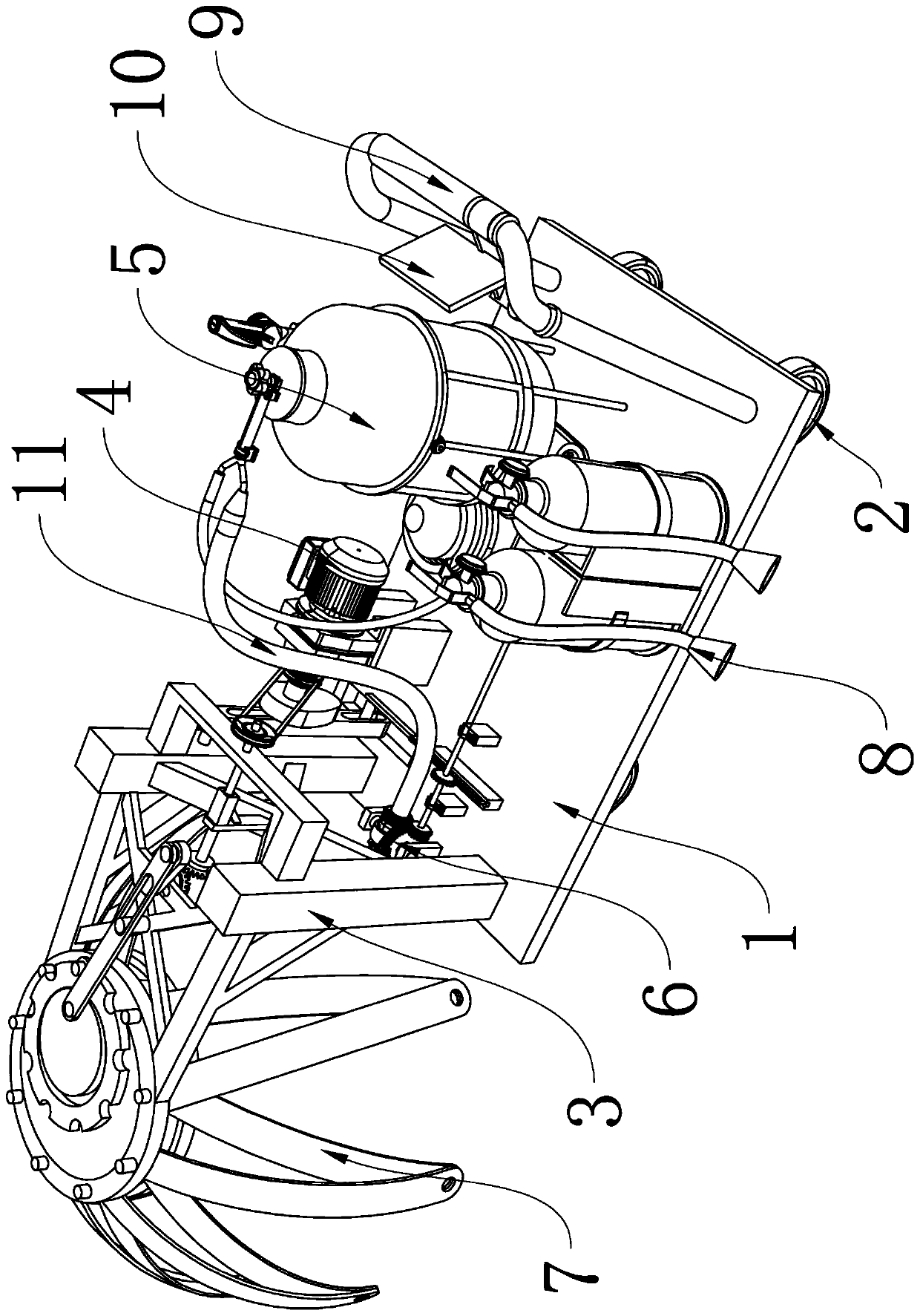

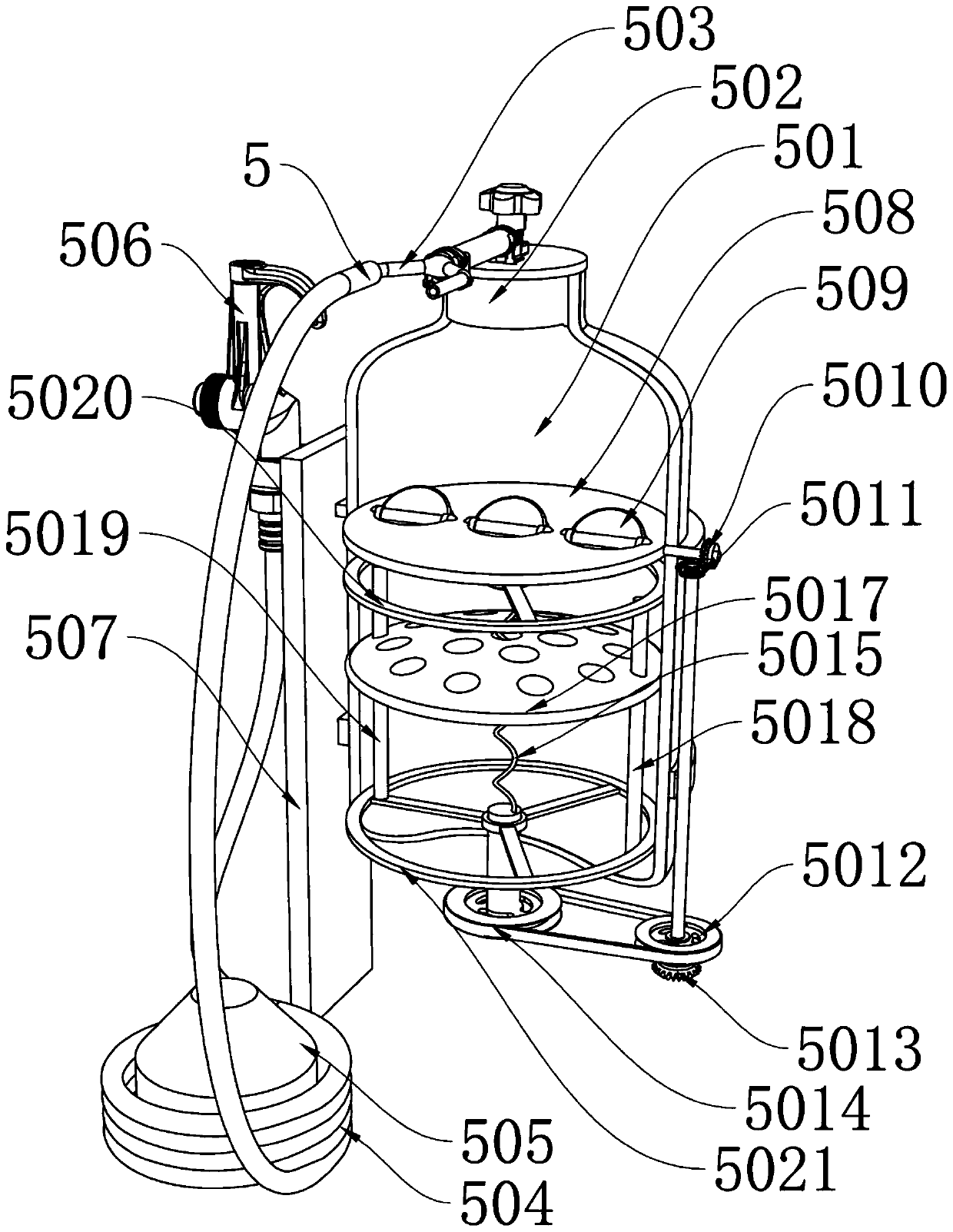

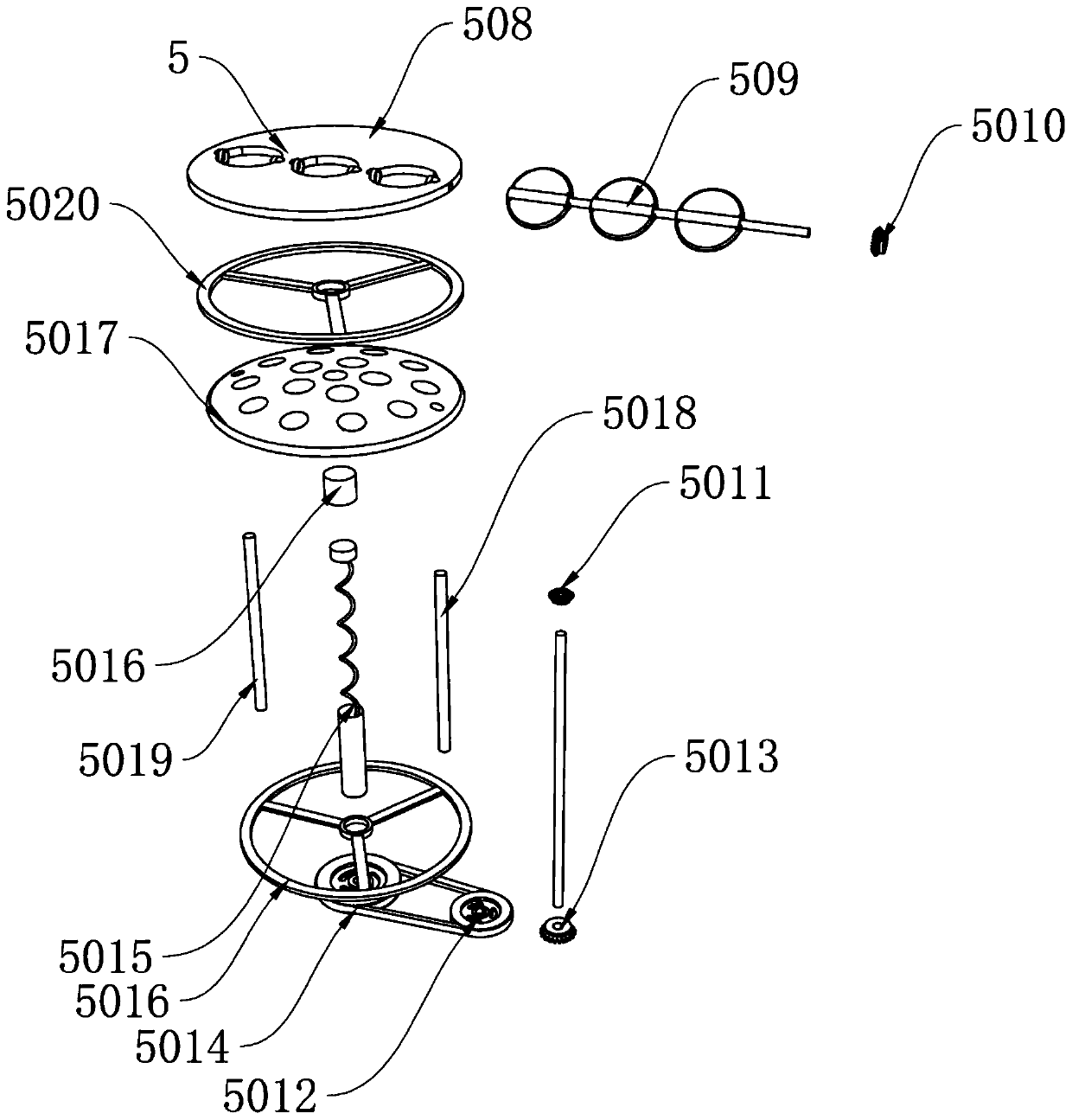

[0026] A fire truck such as Figure 1-5As shown, it includes the cart bottom plate 1, the wheels 2, the external support 3, the motor 4, the solution speed reaction mechanism 5, the fire source root aiming mechanism 6, the oxygen barrier diffusion mechanism 7, the fire extinguisher 8, the push handle 9, the control switch 10 and the first Hose 11; the four corners of the bottom end of the cart bottom 1 are bolted to the wheel 2; the top left part of the wheel 2 is welded with the external bracket 3; the top rear left part of the cart bottom 1 is bolted to the motor 4; the top of the cart bottom 1 is connected by bolts The right middle portion is welded with the solution speed reaction mechanism 5; the top left middle portion of the cart bottom plate 1 is provided with a fire source root aiming mechanism 6, and the rear middle portion of the fire source root aiming mechanism 6 right end is connected with the motor 4, and the fire source root aiming mechanism 6 The top of the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com