Method for preparing highly pure aqueous hydroxylamine solutions

A pure hydroxylamine and aqueous solution technology, applied in the fields of hydroxylamine, inorganic chemistry, distillation and separation, etc., can solve the problems of high price and difficult preparation of hydroxylamine aqueous solution, and achieve the effect of greatly increasing the operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

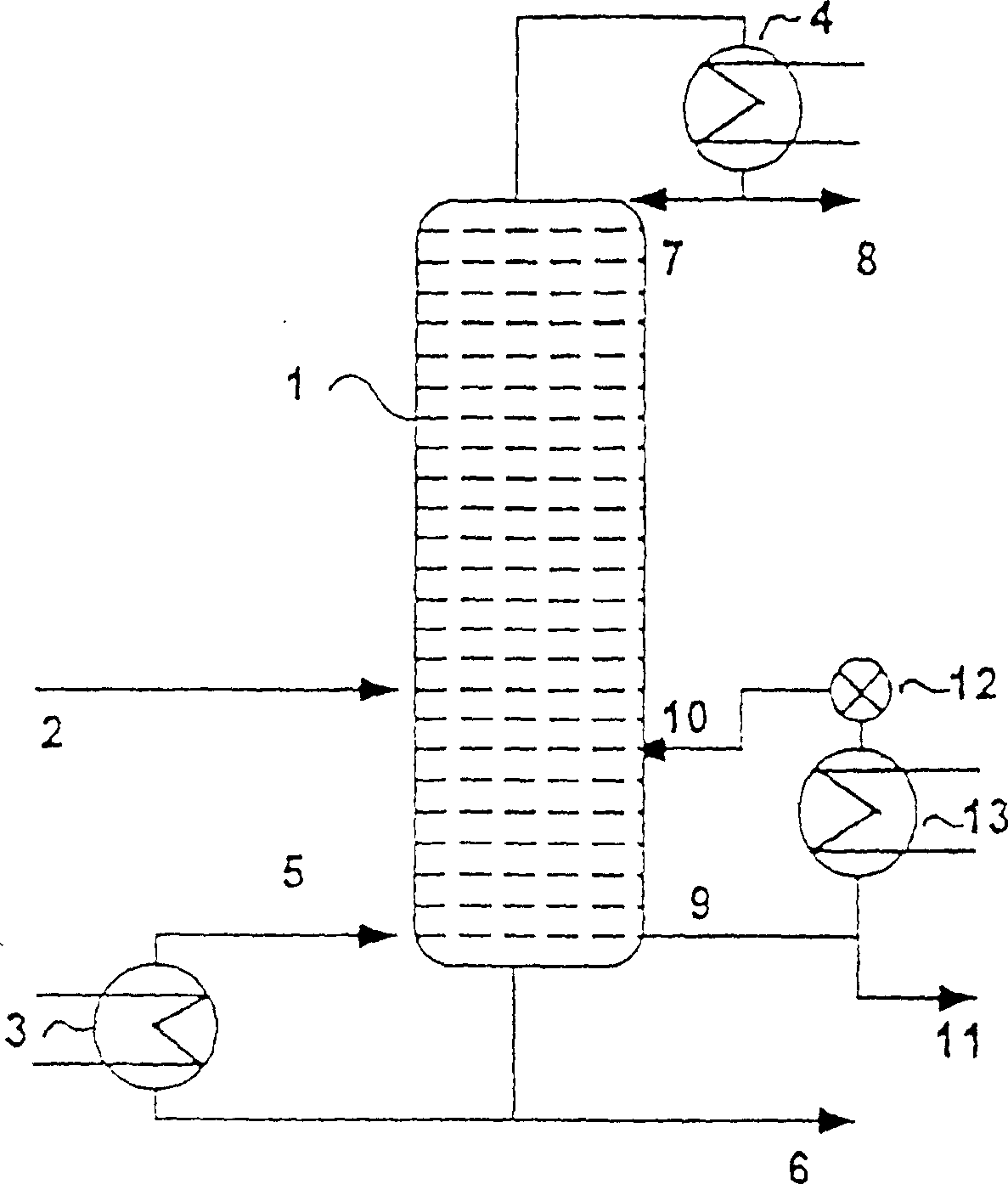

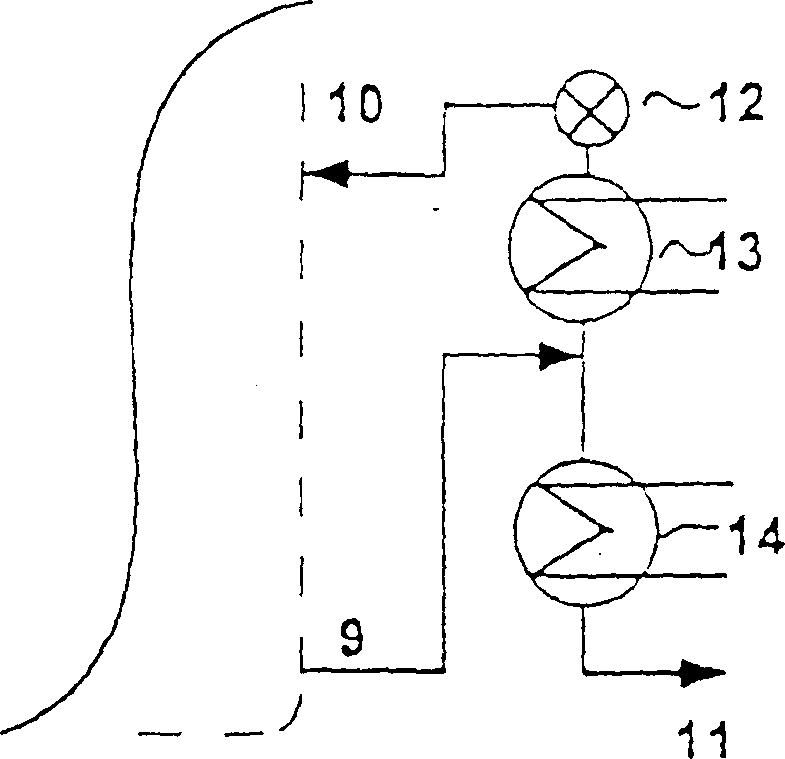

[0046] 1600 g / h of a 3.2% strength by weight, substantially salt-free, stabilized aqueous hydroxylamine solution 2 was fed into a glass bubbler tray column 1 with a diameter of 50 mm and 30 bubbler trays, the feed inlet being on plate 8. The column was operated at 300 mbar. Take a small amount of the same stabilizer that has been dissolved in the hydroxylamine solution, and meter it into column 1 on the No. 30 plate at the top. Water 8 is distilled from the top of tower 1, and the reflux ratio is 0.5. The distillate still contained 0.06% by weight residual hydroxylamine. Approximately 70 ml / h of a 50% strength by weight hydroxylamine solution 6 is pumped off from the bottom of the column. The bottom discharge contained up to 45 ppm sodium sulfate. Below the No. 1 plate at the bottom of the tower, there is also a transfer area leading to the side condenser 13. The back pressure generated by the pressure loss of the sieve plate in the tower causes the steam to be forced to b...

Embodiment 2

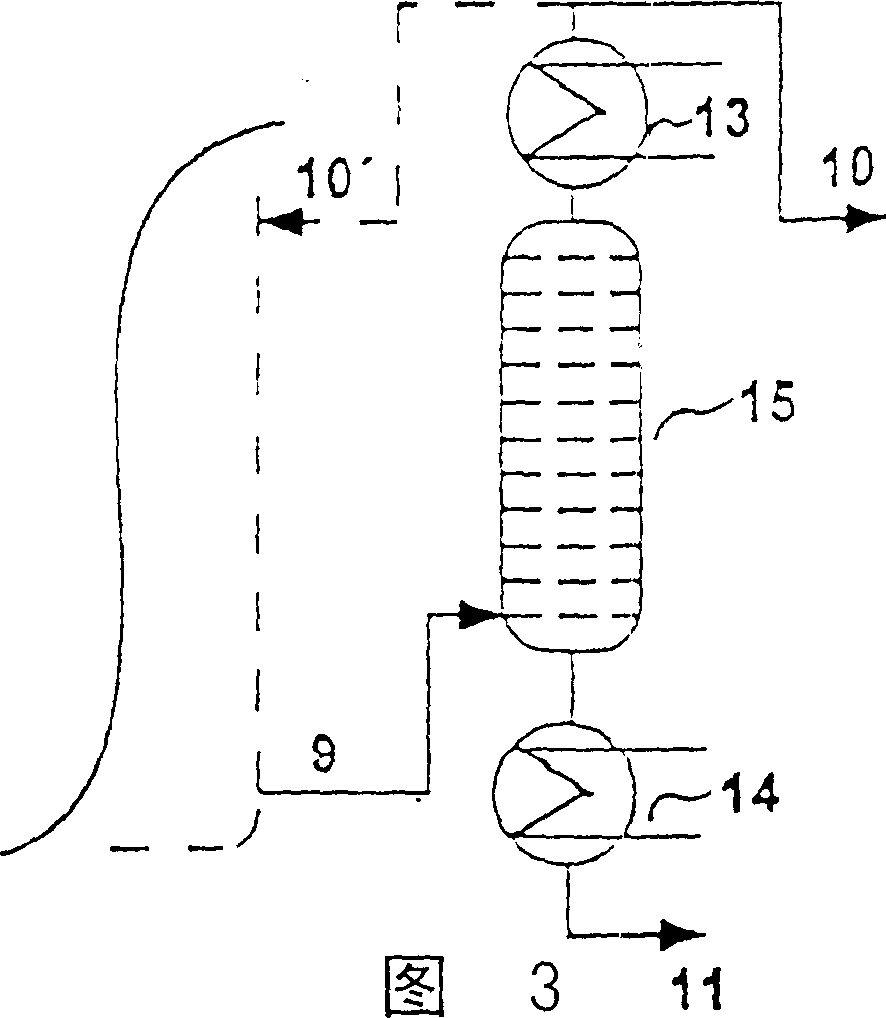

[0048] A hydroxylamine solution with a concentration of about 10% by weight was concentrated to 50% by weight in a 5-meter-high, 0.3-meter-diameter glass bubbler tray at about 77° C. and 0.3 bar. The steam is removed from the bottom of the tower through the PTFE pipe, and sent to the side storage container 51 with double jacket cooling device. Part of the vapor condenses here. The uncondensed vapor returns to the fifth plate of the tower through the PTFE pipeline. The amount of steam is manually limited with a throttle valve. The vapor condensed in the cooling storage tank was concentrated again to 50% by weight (high purity product).

[0049] The obtained hydroxylamine solution (both 50% by weight) has the following composition (metal content is in mg / kg: analytical precision: 0.1 mg / kg):

[0050] Standard product High purity product

[0051] (without side stream production) (with side stream production) boron 3.0 <0.1 sodium 9.0 <0.1 potassi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com