Robot for industry

A technology for industrial robots and detection sensors, which is applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as indoor heat generation, drive source heat generation, and rising cooling costs, and achieve efficient cooling costs, improved action safety, and cooling The effect of cost containment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

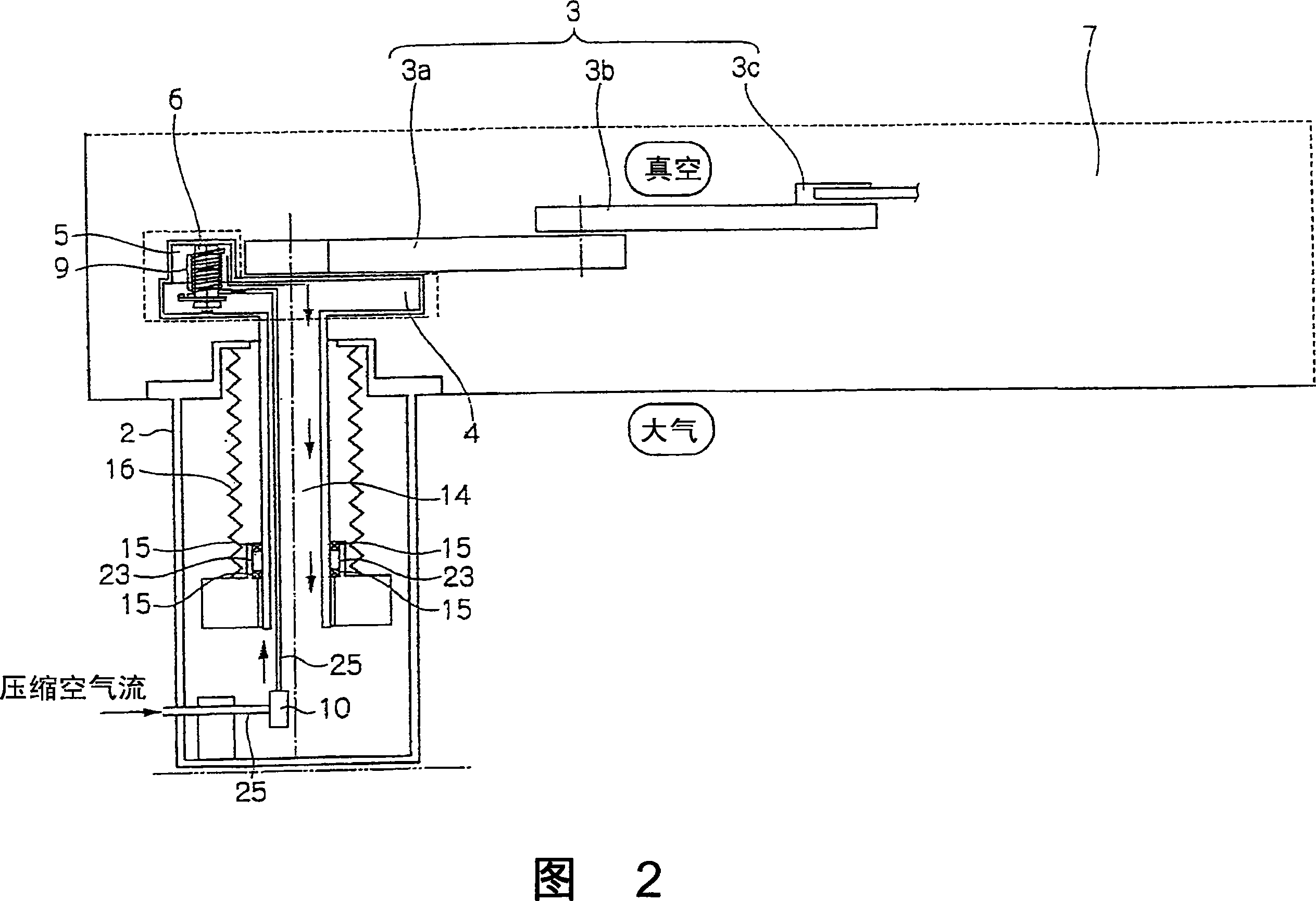

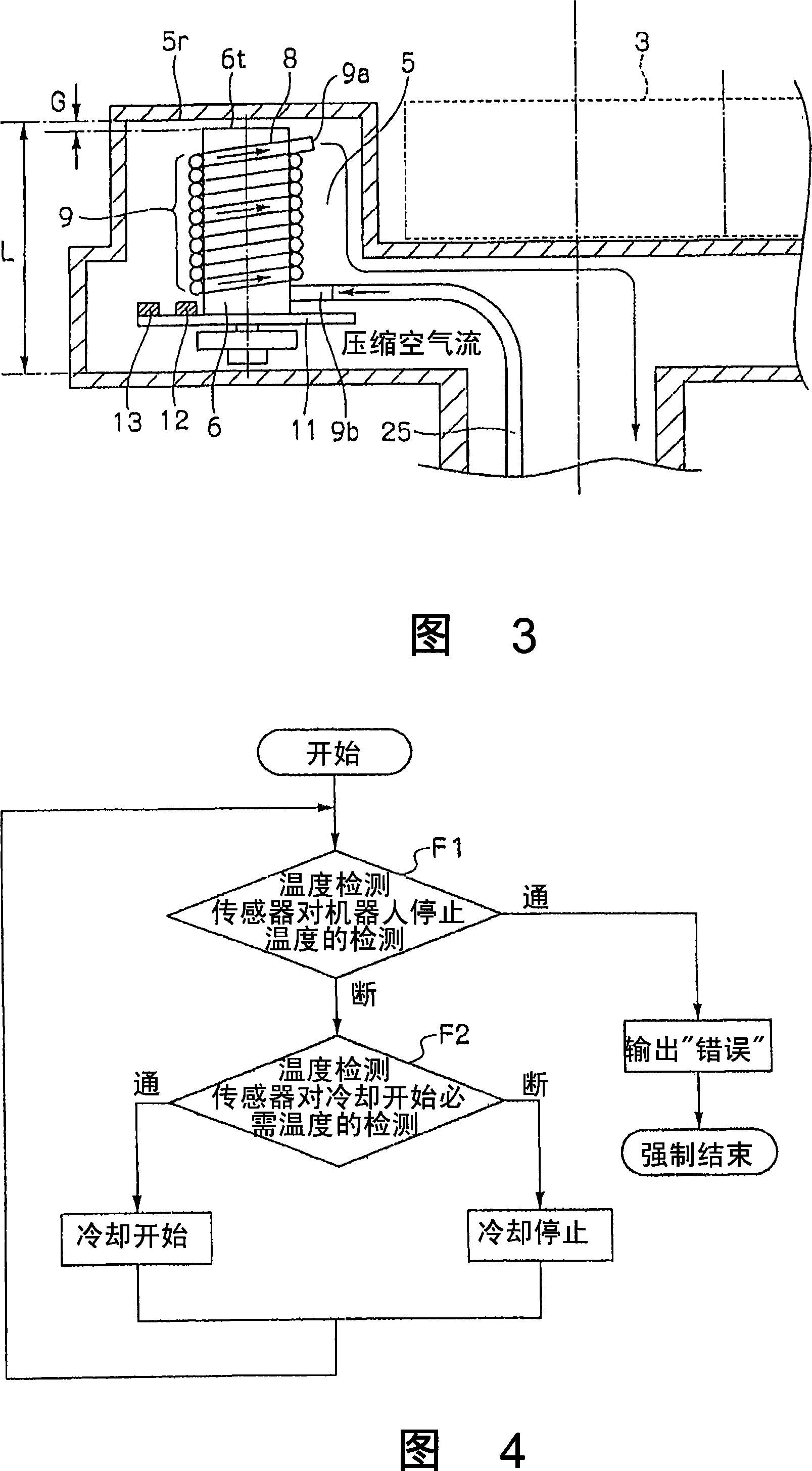

[0060] The best mode for carrying out the present invention will be described below with reference to the drawings. The industrial robot of the present invention is not limited to the following description and drawings insofar as it has its technical features. In the following description, a generally used motor (motor for driving an arm) is described as an example of a drive source, but of course, the drive source used in the present invention is not limited to a motor. In addition, corresponding to the description given by taking the motor as an example, the storage chamber for accommodating the driving source is referred to as a "motor storage chamber". Similarly, the portion of the storage chamber that accommodates the drive source is referred to as a "motor storage portion".

[0061] [First Embodiment]

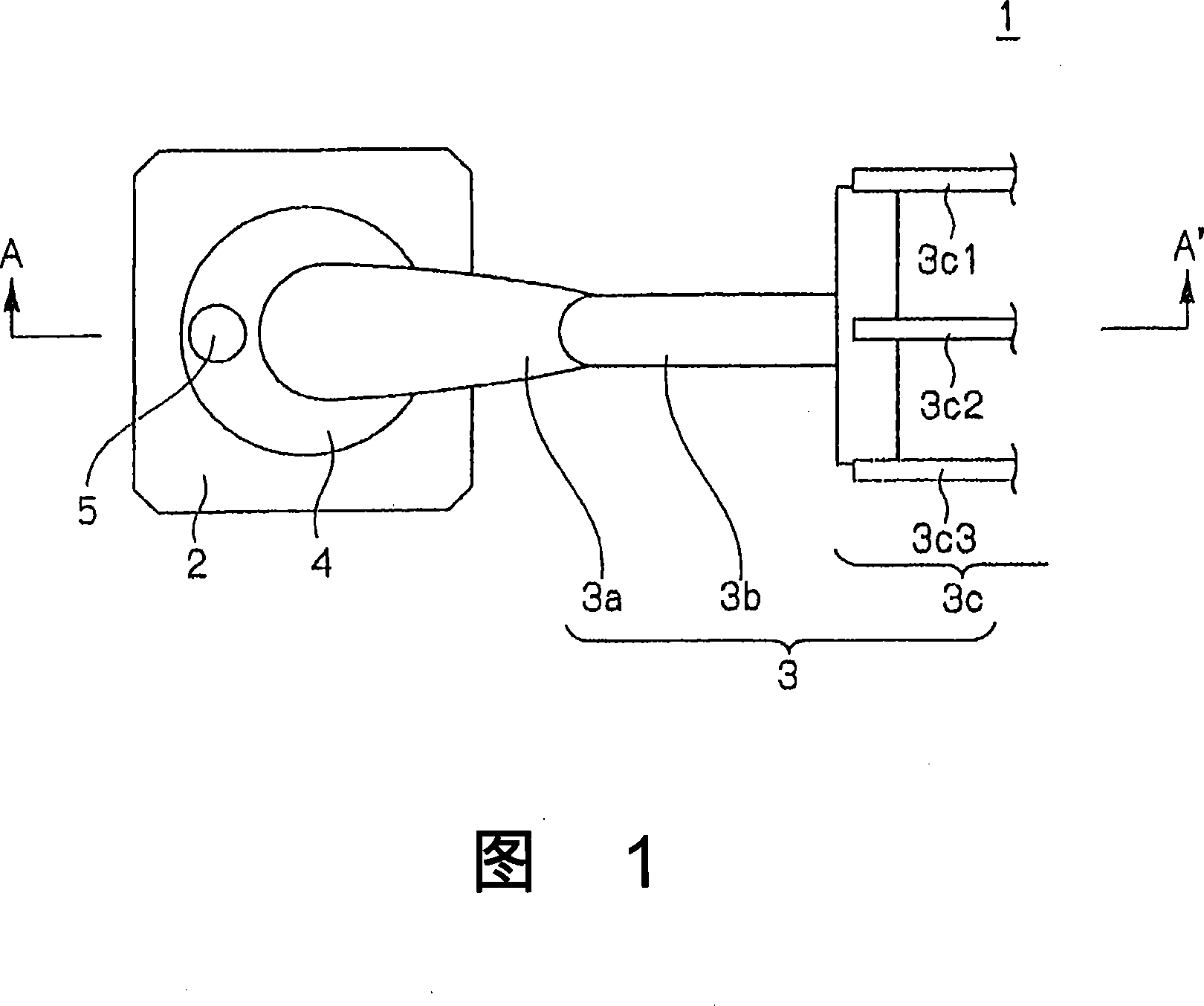

[0062] FIG. 1 is a schematic plan view of an industrial robot according to a first embodiment of the present invention. The industrial robot 1 shown in FIG. 1 is a typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com