Tooling comprising a mould cavity made of porous material, a patty forming machine and mould cavity washing machine comprising such tooling

A technology of forming machine and washing machine, applied in slaughtering, meat processing equipment, food science and other directions, can solve the problem of cleaning cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

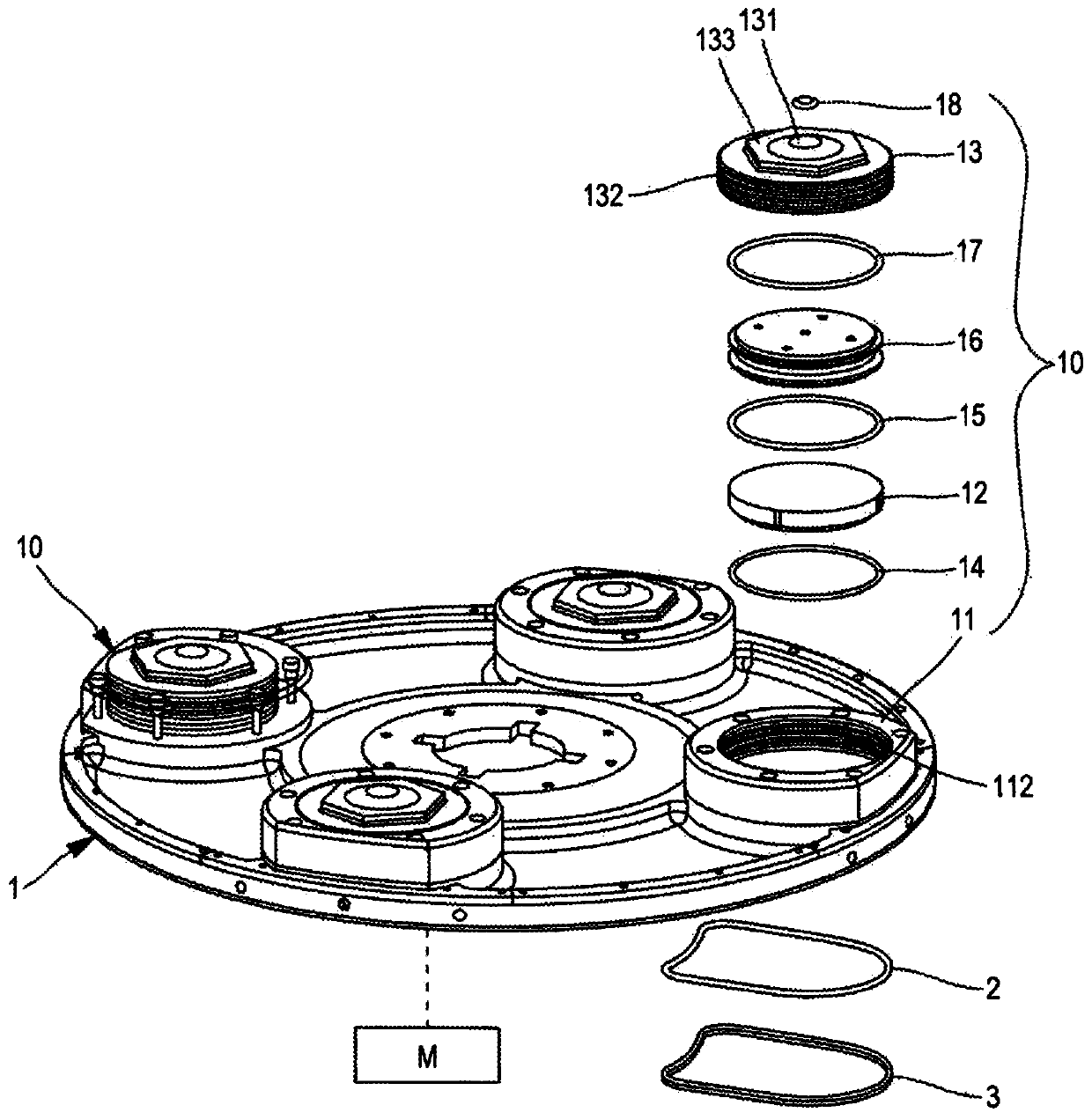

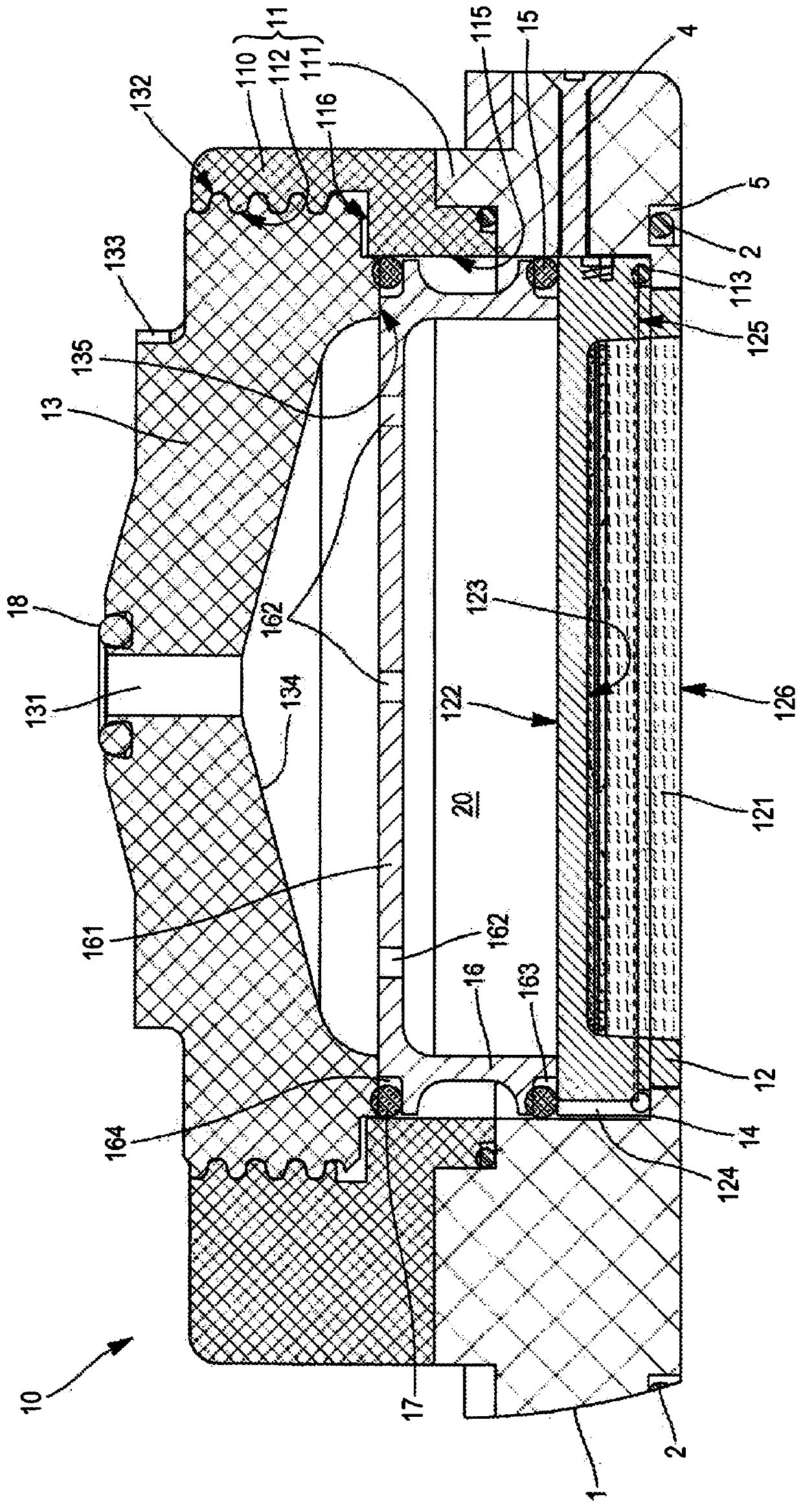

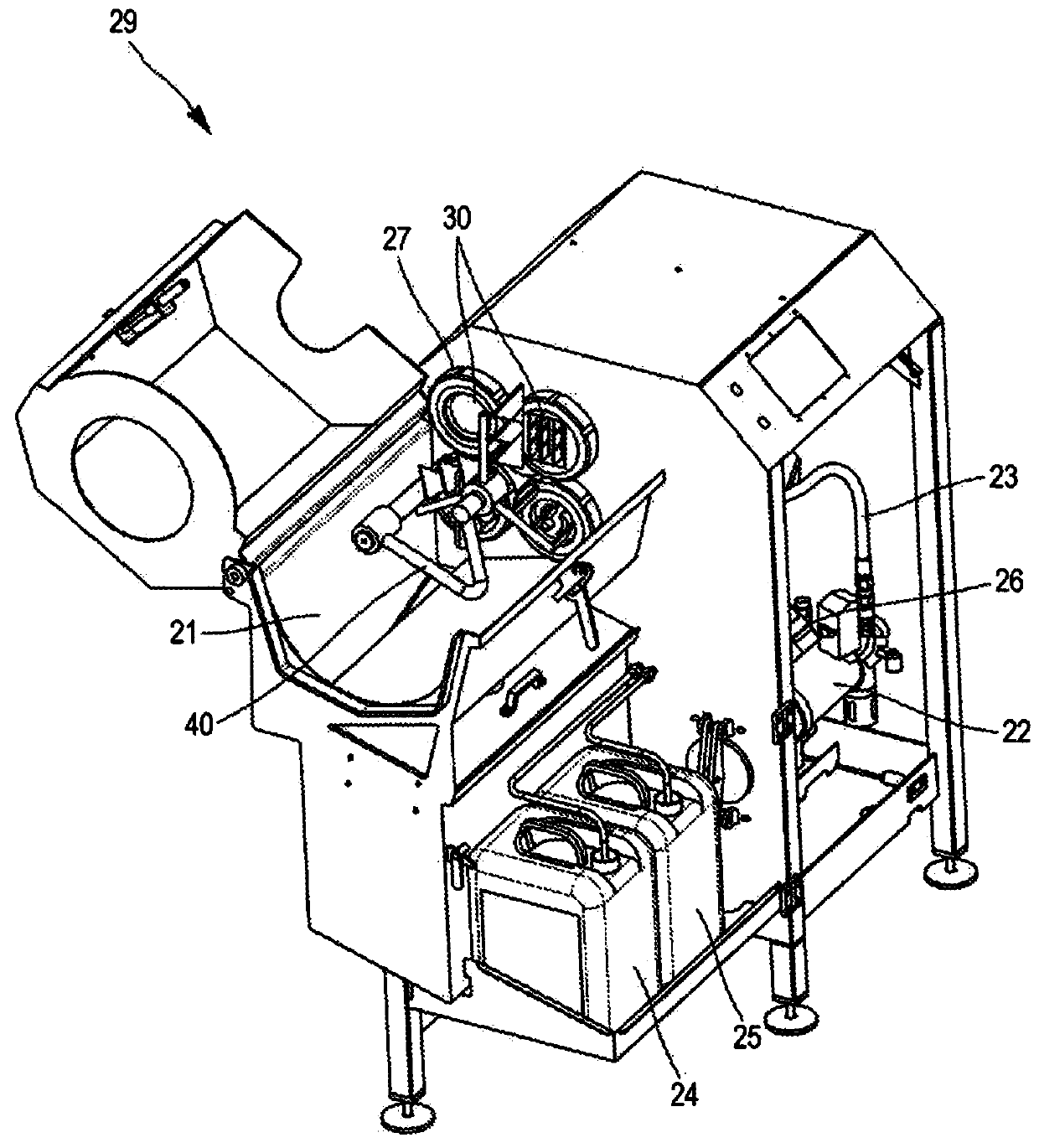

[0043] refer to figure 1 and figure 2 , a first embodiment of the device 10 according to the invention and its use in a machine M for shaping pies will be described. The mold (here in the form of a circular disc 1 ) is rotating, on which a series of devices 10 according to the invention are positioned, preferably evenly distributed over the circumference of the circular disc 1 . exist figure 1 In the embodiment shown, the circular disc 10 comprises four sets of devices 10 according to the invention. This type of mold is used to supply food pieces from below, a sealing system is provided to ensure the supply, said sealing system consists of a joint 2 and a core (jonc) 3, both housed in a groove 5, the groove 5 An opening is formed on the inner surface of the circular disc body 1 surrounding the device 10 .

[0044] The device 10 according to the invention is therefore intended for forming pies from food scraps. Here it includes:

[0045] - The cavity holder 11 fastened ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com