A vibrating grading sieve

A grading sieve and sieve technology, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc., can solve problems such as adjustment, inability to realize output, and horizontal distribution of materials without vibrating grading sieve, so as to achieve uniform lateral distribution and high angle Easy and fast adjustment, convenient screen angle adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

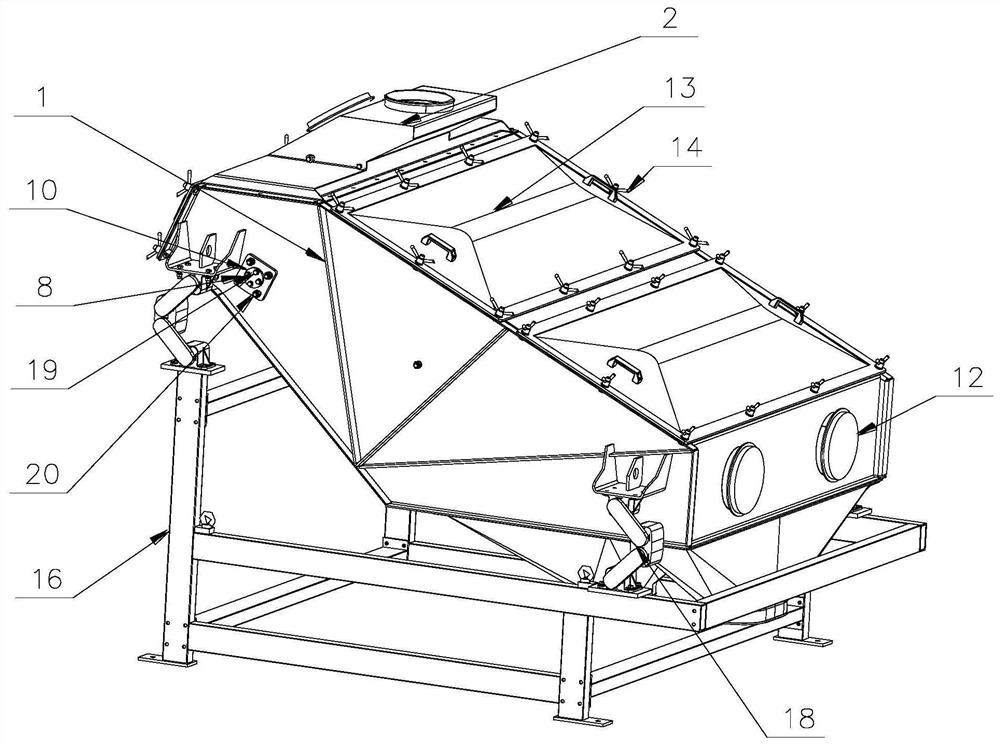

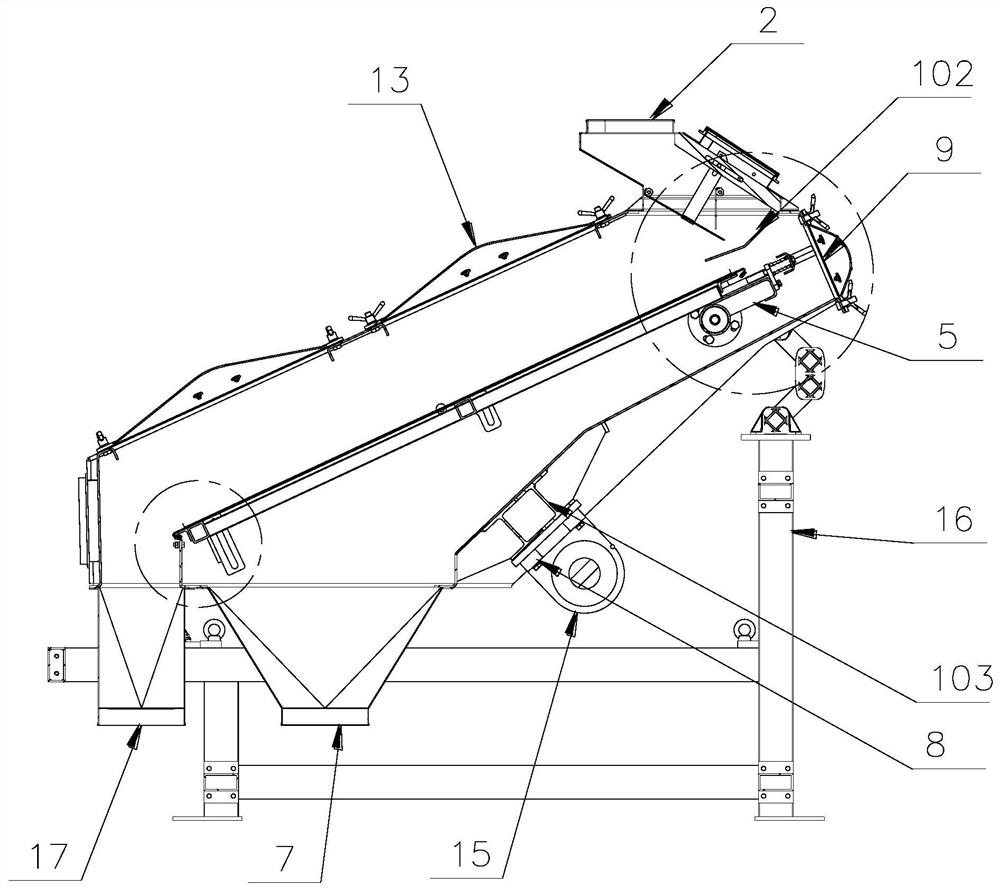

[0074] see Figure 1-Figure 17 , a vibrating grading screen, comprising a sieve ship weldment 1, a feed assembly 2, a screen assembly 3, a screen hanger assembly 4, a screen hanger assembly support weldment 5, a screen adjustment bracket 6, a finished product port 7, and an anti-loosening pad Sheet 8, small operating door 9, screen assembly fixed pin 10, material retaining plate 11, observation hole cover 12, upper cover assembly 13, double handle handle 14, vibration motor 15, frame 16, small miscellaneous opening 17, rubber Support 18, shaft head fixing bolt 19, reinforcement seat fixing bolt 20;

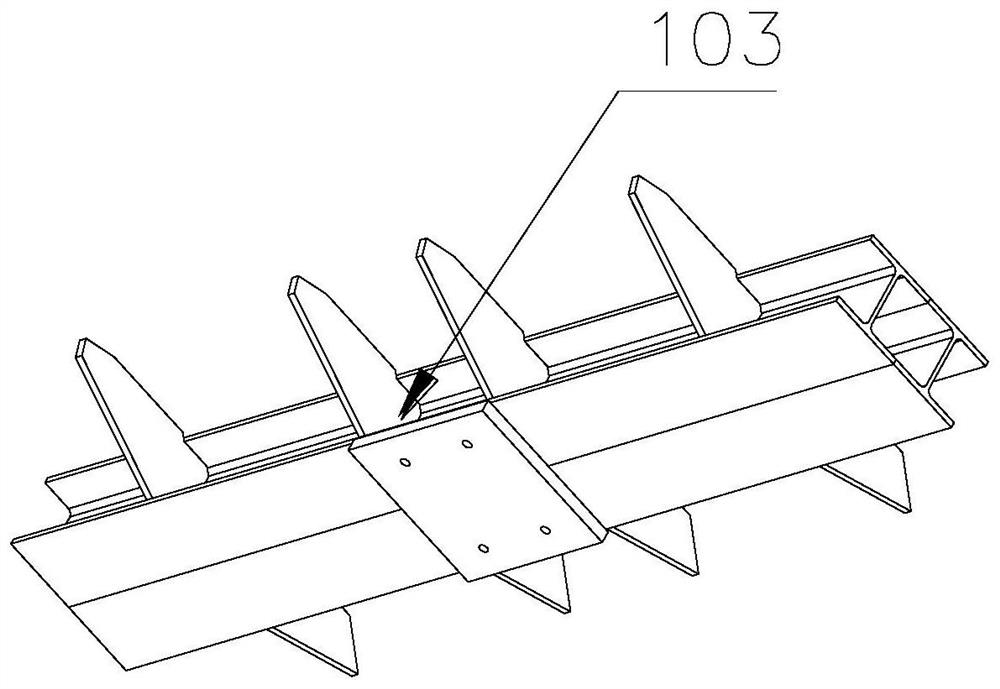

[0075] The sieve ship weldment 1 includes a sieve ship reinforcement seat 101, a sieve ship spreading board 102, a motor installation beam assembly 103, a sieve ship side plate 1 104, a sieve ship side plate 2 105, a top cover fixing bolt 106, and a sieve ship support seat 107 , Partition plate 108, sieve ship bottom plate 109.

[0076] The reinforcement seat 101 of the sieve sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com