Lapper with air feeding device for cotton passing face

A technology of air supply device and lapping machine, which is applied in the direction of lapping mechanism, textile and paper making, fiber processing, etc. It can solve the problem that the unevenness of cotton laps is difficult to reach the ideal value, destroying the uniform distribution of cotton layers, rolling and crowding of cotton blocks and other problems, to achieve the effect of reducing the transverse unevenness, improving the quality of laps, and ensuring the quality of yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

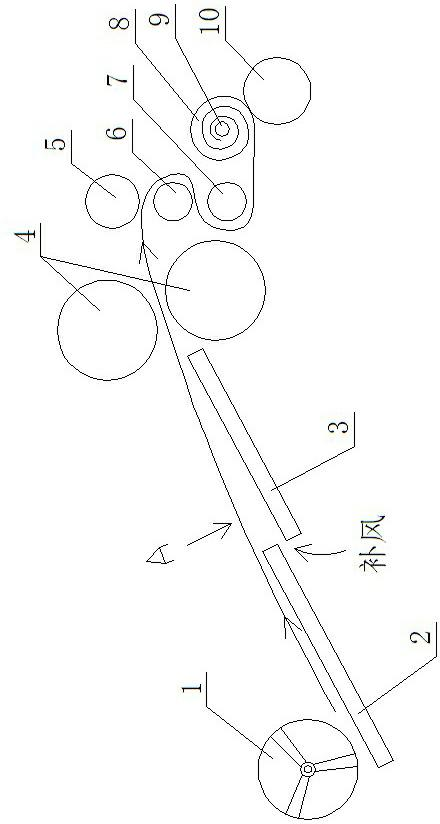

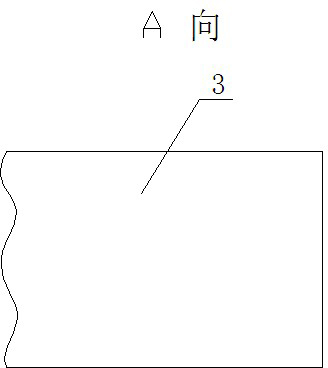

[0010] Such as figure 1 As shown, the lapping machine with the cotton curved surface supplementary air device includes a beater support plate 2, a comprehensive beater 1 is arranged above the front end of the beater support plate 2, a cotton board 3 is arranged at the rear end of the beater support plate 2, and a cotton board 3 is arranged at the rear end of the beater support plate 2. The front end gap is arranged on the rear end below of the beater supporting plate 2, and the front end face of the cotton board 3 is a curved surface. Such as figure 2 shown.

[0011] A pair of dust cages 4 for agglomerating the cotton layer are arranged at the rear end of the cotton passing board 3, and the rear side of the pair of dust cages 4 are three pressing rollers 5, 6, 7. The cotton block output by the comprehensive beater 1 is adjusted by the curved surface air supply plate 3 to form a uniform cotton block adsorbed on the surface of a pair of dust cages 4, and merged into a uniform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com