Submersed nozzle for continuous casting moulds

A continuous casting crystallizer and immersion technology, which is applied in the direction of casting molten material container, casting equipment, metal processing equipment, etc., can solve the problem of not being able to alleviate mold slag agglomeration and corner cracks, and it is difficult to greatly reduce stream damage, etc. problems, to achieve the effect of improving the continuous casting process, improving the quality of the slab, and reducing the effect of cold steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

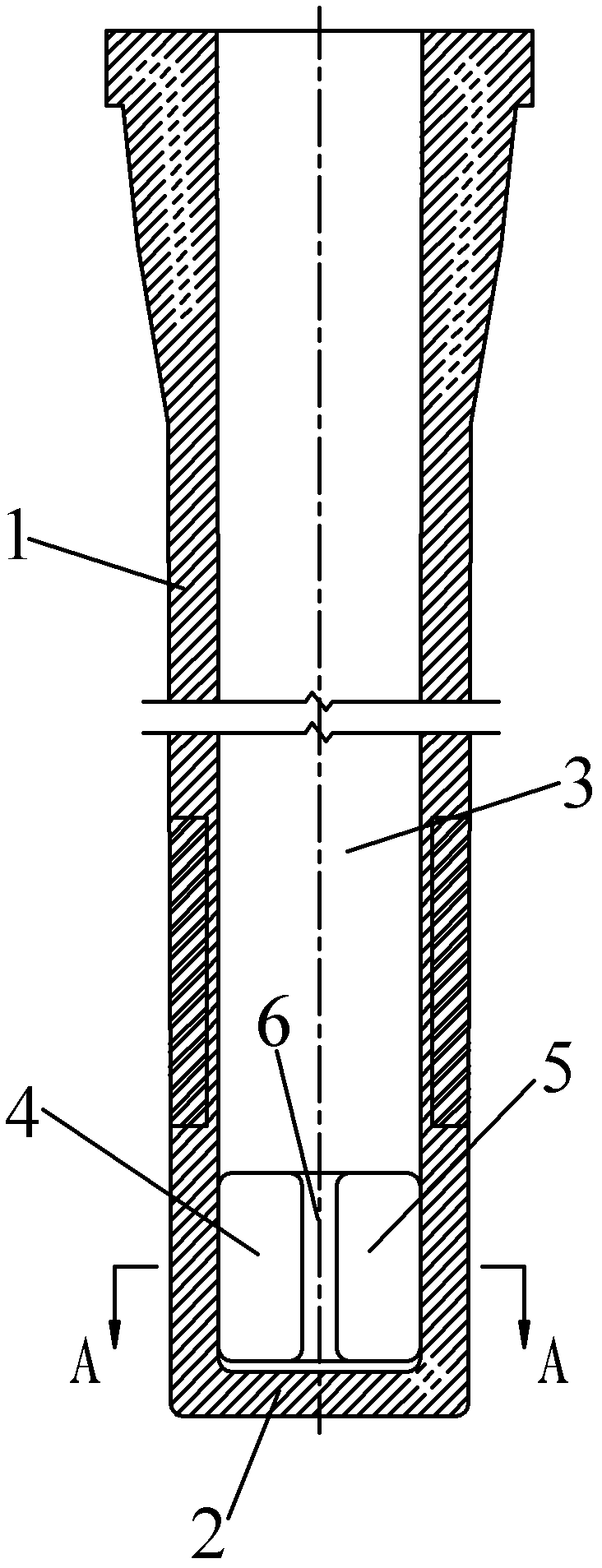

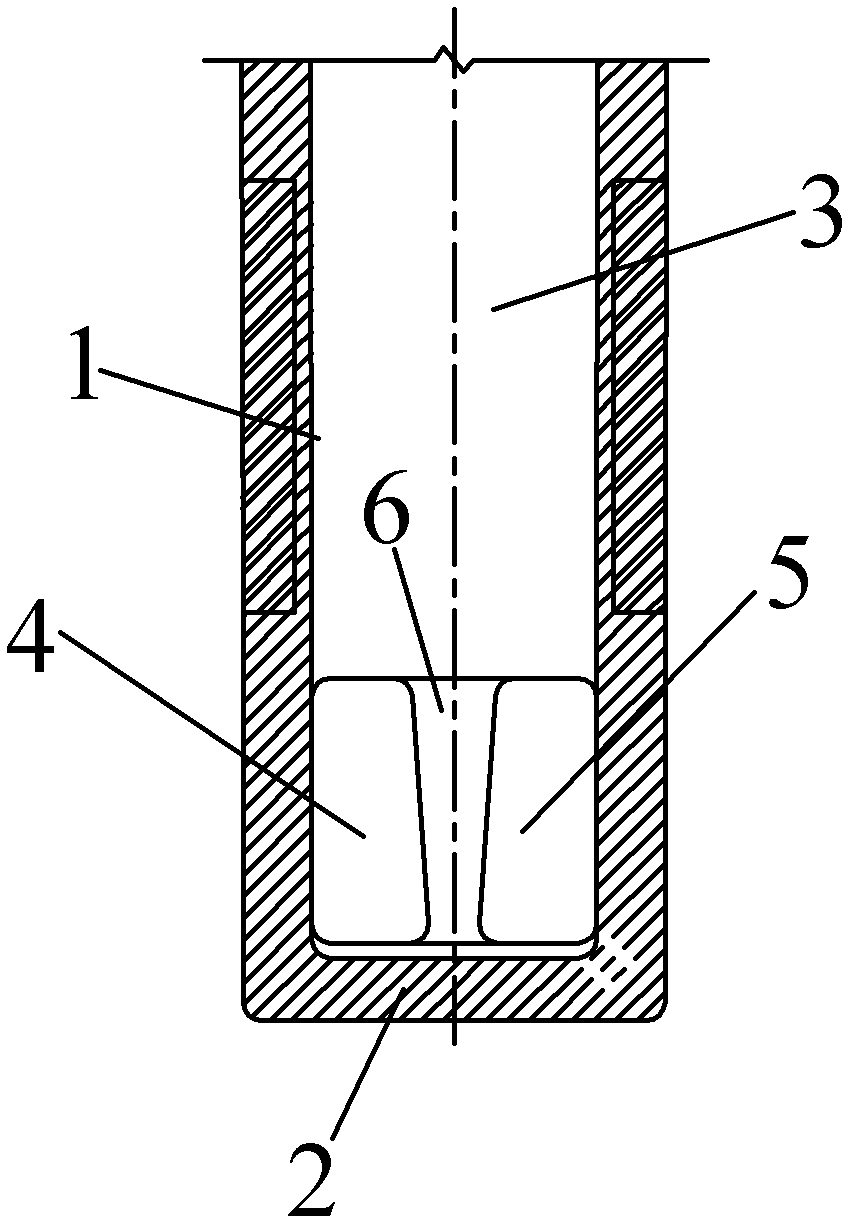

[0030] When pouring the slab, you can use such as Image 6 The shown two-sided four-hole submerged nozzle is used for pouring, and the cross-sections of the submerged water side wall 1 and the inner cavity 3 are both flat with front and rear planes and left and right arc surfaces. The bottom 2 of the submerged nozzle is set in a concave shape, the inclination angle of the upper and lower walls of the first side hole 4 and the second side hole 5 is -15°, the inclination angle of the outer wall surface is 20°, and the side holes are chamfered square, The chamfer radius is 10mm. The width of the spacer 6 between the holes on both sides is 15mm. During pouring, the spacer 6 is aligned with the center of the narrow surface of the slab crystallizer 7, and the molten steel enters from the upper opening of the inner cavity 3 and flows out from the first side hole 4 and the second side hole 5, which can reduce the temperature of the high temperature molten steel. The impact on the ce...

Embodiment 2

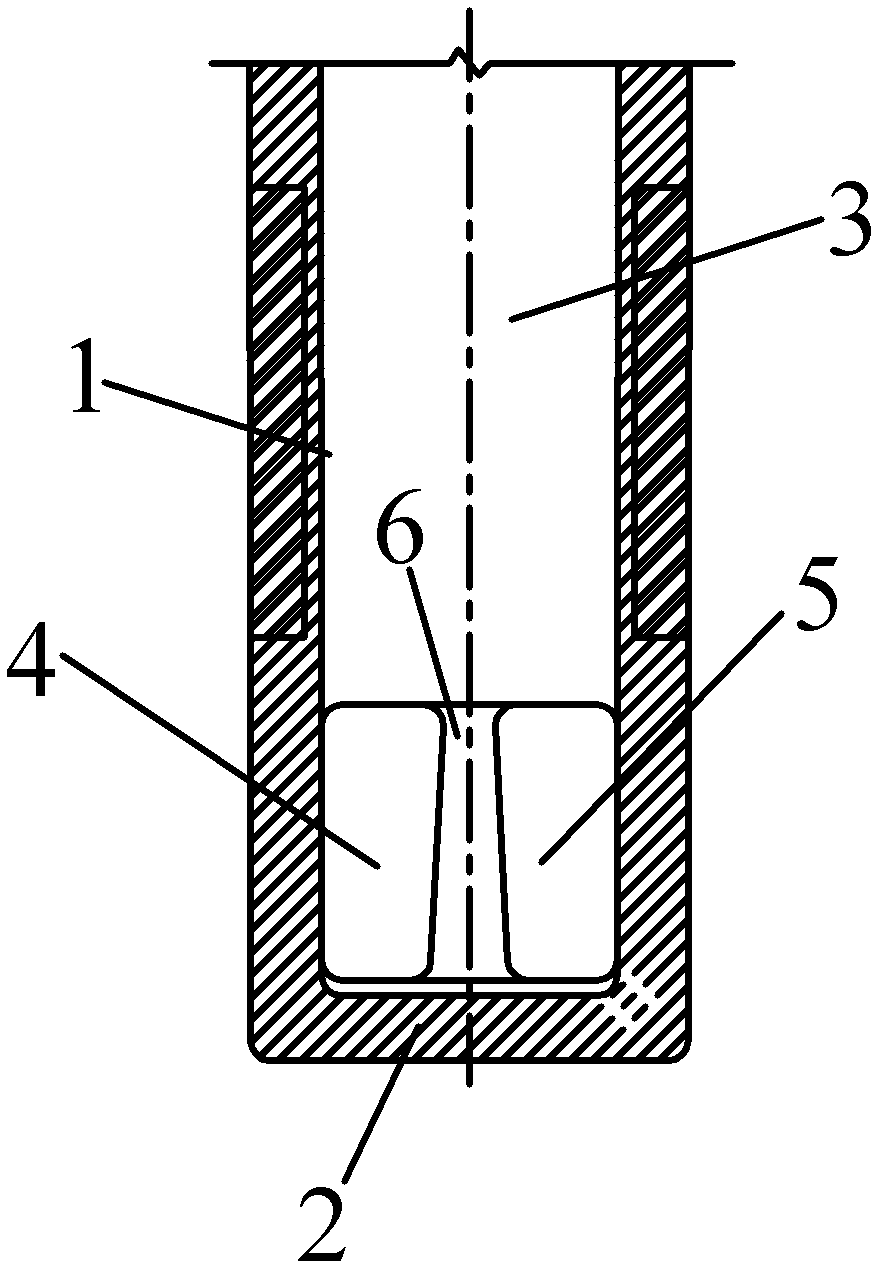

[0032] When pouring blooms, such as Figure 7The shown two-sided four-hole submerged nozzle is poured, and the cross-section of the submerged water side wall 1 and the inner cavity 3 is circular. The bottom 2 of the submerged nozzle is set in a concave shape, the inclination angle of the upper and lower walls of the first side hole 4 and the second side hole 5 is -10°, the inclination angle of the outer wall surface is 30°, and the side holes are chamfered square, The chamfer radius is 10mm. The width of the spacer 6 between the holes on both sides is 15 mm. When pouring, the spacer 6 is aligned with the center of the narrow surface of the bloom mold 8, and the molten steel enters from the upper opening of the inner cavity 3 and flows out from the first side hole 4 and the second side hole 5, which can reduce the temperature of the high temperature molten steel. The impact on the thinner billet shell in the center of the narrow face, and the temperature compensation for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com